Ring type dinner plate cleaning equipment

A technology for cleaning equipment and dishes, which is applied to cleaning equipment, tableware washing machines/washing machines, tableware washing machines/rinsing machine parts, etc. and other problems, to achieve the effect of smooth transmission process, improved cleaning effect and high cleaning quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

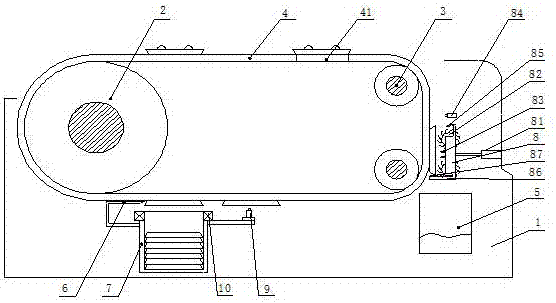

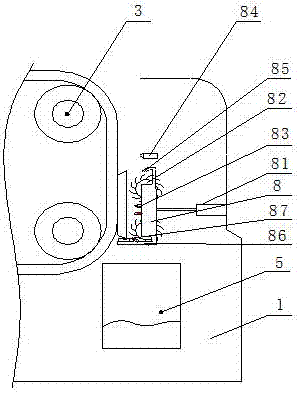

[0033] During specific implementation: if Figure 1-2As shown, a ring-type dish cleaning device includes a casing 1, a driving wheel 2 connected to one side of the casing 1, a driven wheel 3 connected to the other side of the casing 1, and a driven wheel 3 wound around the driving wheel 2 and driven The conveyor belt 4 on the moving wheel 3; the conveyor belt 4 is provided with a dinner plate fixing device 41 capable of fixing the dinner plate outside it, and below the position of the front side of the conveyor belt 4 in the direction of rotation, there is a swill for holding leftovers Container 5, on the housing 1 of conveyer belt 4 lower positions, be also provided with and be used to release the meal dish release mechanism 6 that meal dish is fixed, the below that the conveyer belt of meal dish release mechanism position is directly opposite is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com