A hierarchical core-pulling method for injection molds

An injection mold and mold technology, applied in the field of grading core pulling of injection molds, can solve problems such as large resistance, easy failure of core pulling action, and reduce reset resistance, and achieve the effects of ensuring reliability, avoiding action failure, and reducing reset resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: a kind of graded core-pulling method of injection mold, comprises the following steps:

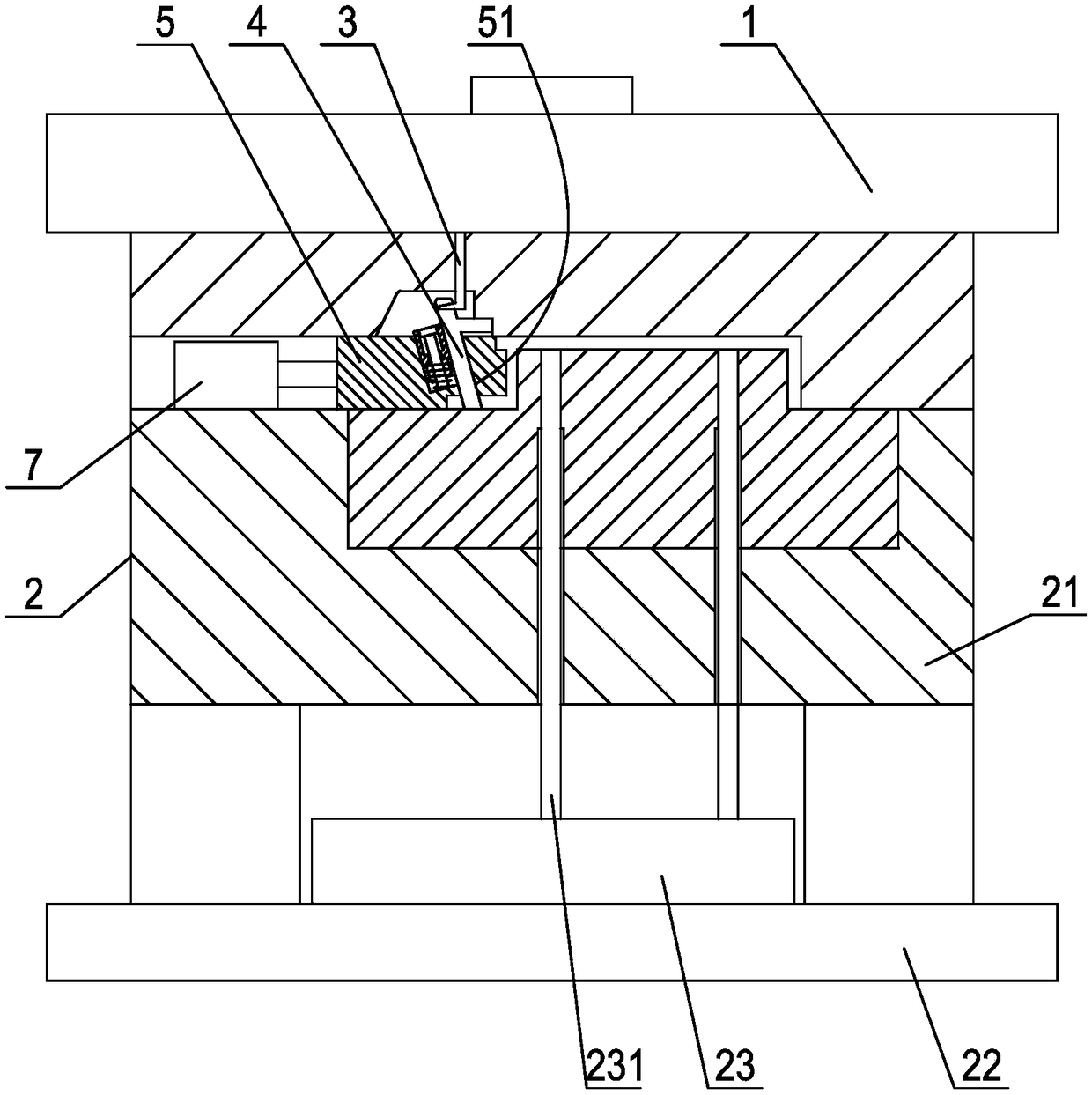

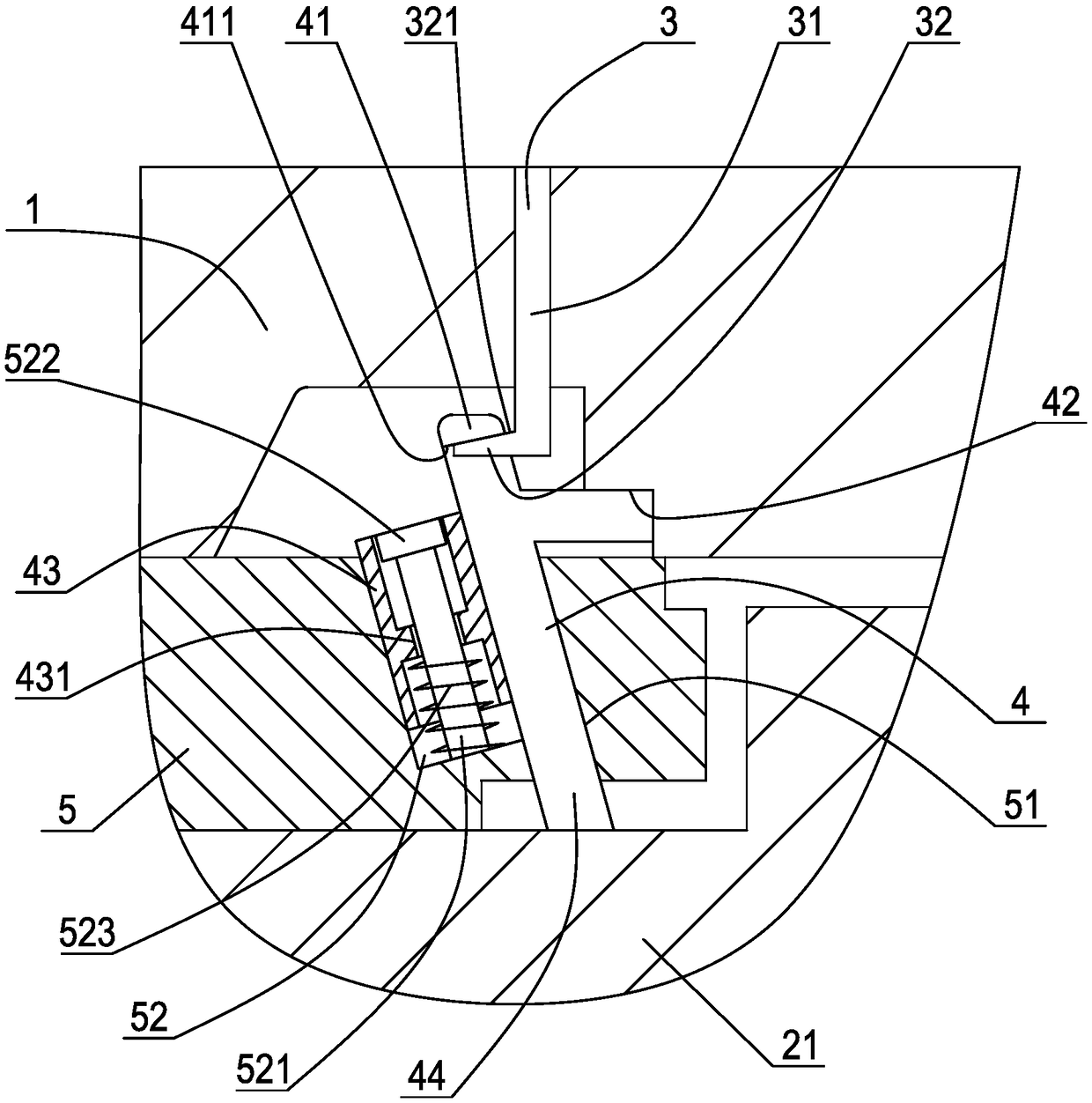

[0037] a. When the mold cavity in the mold closing state is filled with molten plastic and cooled and shaped, the movable mold retreats and separates from the fixed mold, and the lower end of a vertical core-pulling rod 3 fixed on the fixed mold is hooked The tail end of the core-pulling core allows the core-pulling core to move axially backward from the forming position obliquely in the inclined guide hole 51 of the core-pulling slider. The core-pulling slider is used to shape the lateral shape of the product. The core-pulling core is used for the inclined hole groove in the lateral shape of the molded product, and the core-pulling direction of the core-pulling slider and the core-pulling core is inconsistent. When the forming end of the front end of the core-pulling core withdraws from the inclined hole groove of the product and retracts into the guide hole, the firs...

Embodiment 2

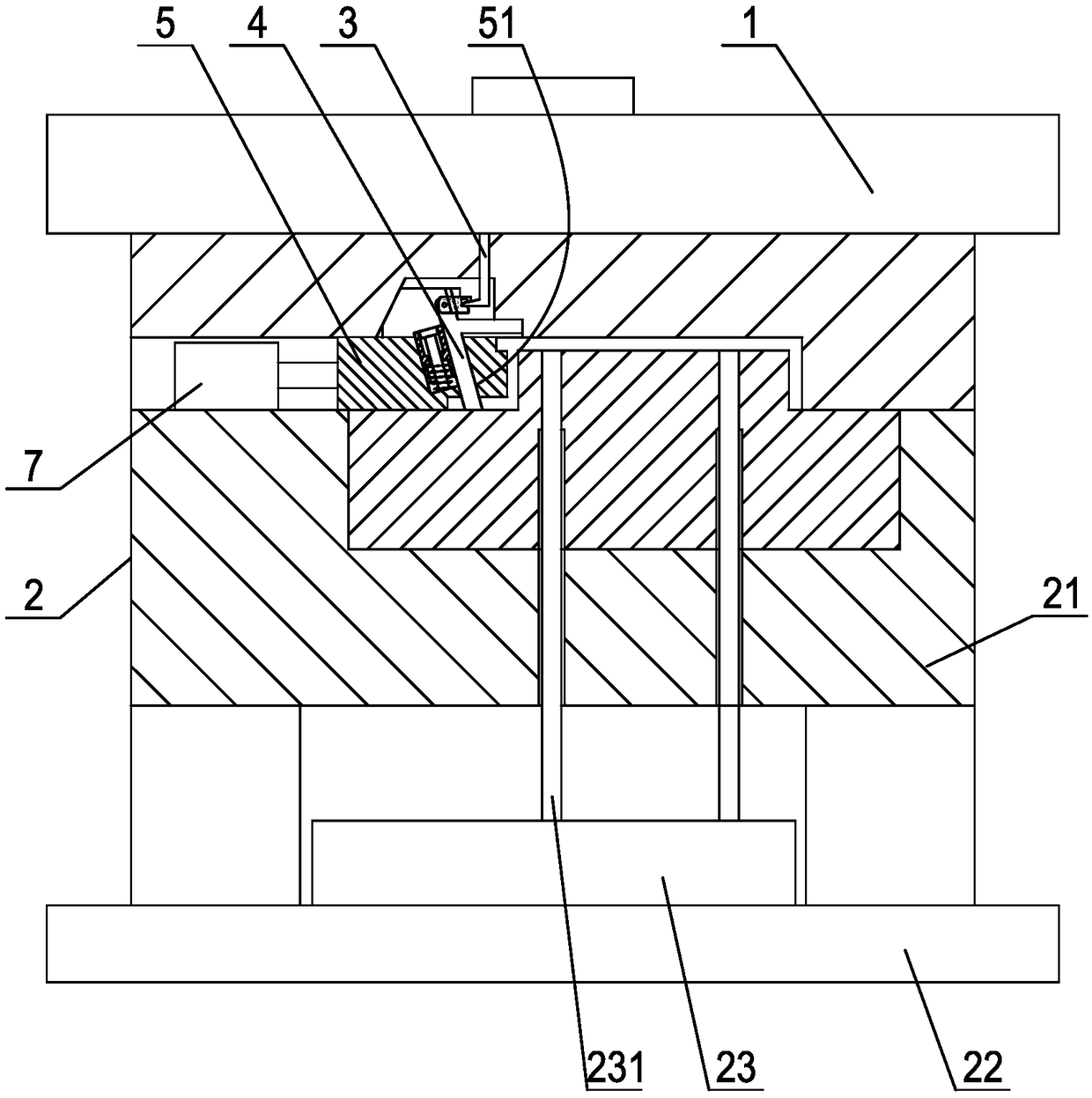

[0045] Embodiment 2: as image 3 , Figure 4 Shown, a kind of graded core-pulling method of injection mold comprises the following steps:

[0046]a. When the mold cavity in the mold closing state is filled with molten plastic and cooled and shaped, the movable mold 2 moves back and separates from the fixed mold 1, and the lower end of a vertical core-pulling rod 3 fixedly arranged on the fixed mold Hook the tail end of the core-pulling core 4 to move the core-pulling core obliquely and axially backward from the molding position in the inclined guide hole 51 of the core-pulling slider 5 . When the forming end of the front end of the core-pulling core withdraws from the inclined hole groove of the product and retracts into the guide hole, the first-level core-pulling of the product is completed. At this time, the tail end of the core-pulling core that moves obliquely forms a longitudinal displacement on the one hand. , producing a lateral displacement. The core pulling rod in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com