Method for manufacturing air spring

A technology of air springs and airbags, which is applied in the field of manufacturing air springs, can solve the problems of time-consuming and labor-intensive assembly process, increase the risk of air spring leakage, time-consuming and labor-intensive problems, and achieve good air tightness and simple installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] figure 1 A flowchart of the method of manufacturing the air spring 100 in this embodiment is shown. The method includes the following steps:

[0026] S10: inserting the first end of the straight cylindrical air-sac blastocyst into the clasp, so that the clasp abuts against the radially protruding convex ring on the second end of the air-sac blastocyst.

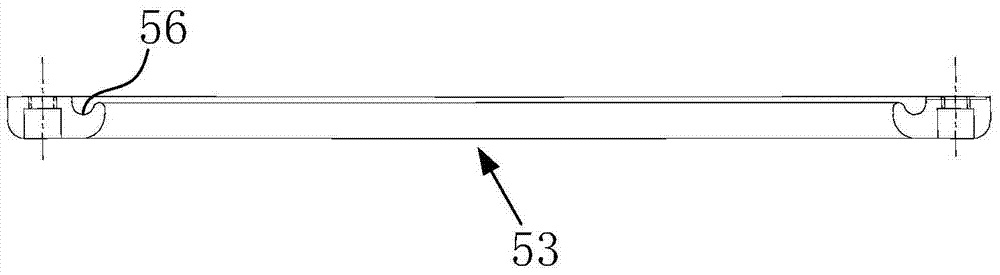

[0027] Such as figure 2 As shown, air spring 100 includes retaining ring 53 . The clasp 53 is a ring structure, preferably a ring. Buckle 53 generally adopts steel ring. The buckle 53 is provided with a plurality of through holes for bolts to pass through. The through hole is preferably a stepped hole. A plurality of through holes are uniformly distributed sequentially around the axis of the buckle ring 53 .

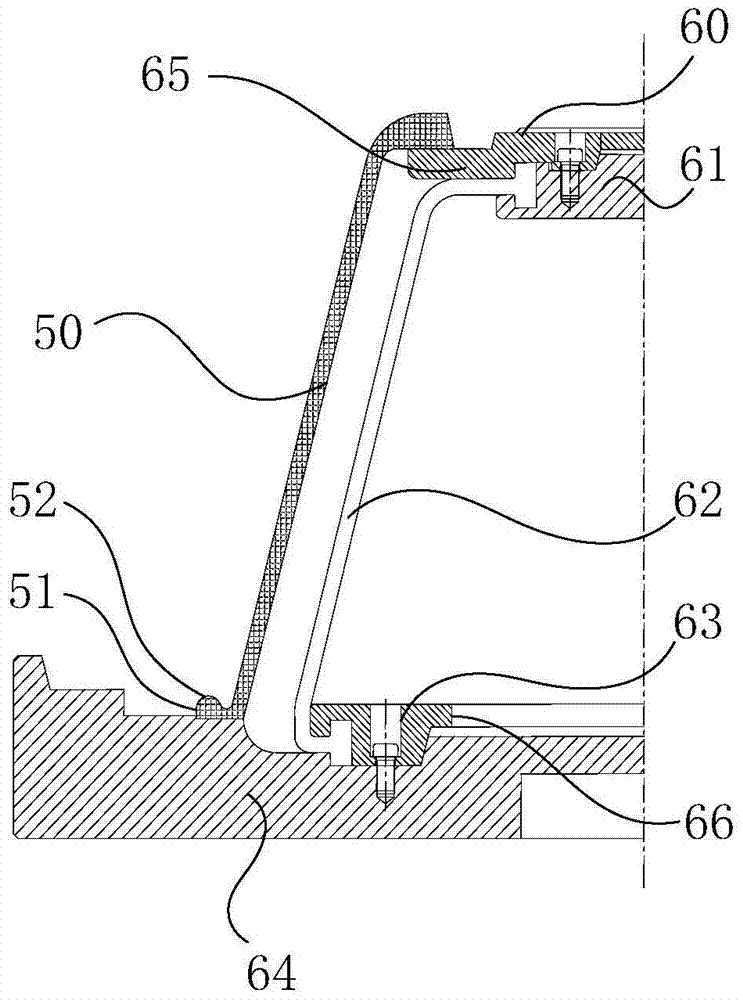

[0028] Such as image 3 As shown, the airbag blastocyst 50 is made of rubber that has not been vul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com