Electronic dobby with positive lubrication

A dobby, active technology, applied in dobby, textile, textile and paper making, etc., can solve problems such as inability to obtain comprehensive or overall lubrication effect, impact on service life of eccentric disc bearing and swing arm, lack of lubrication effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

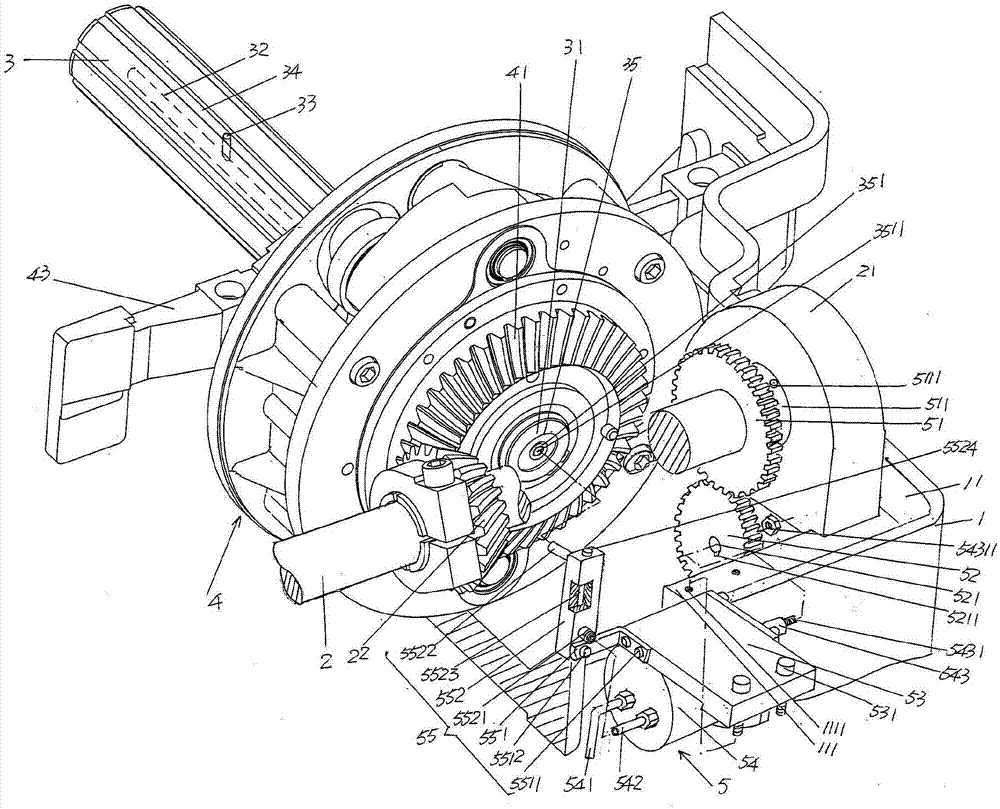

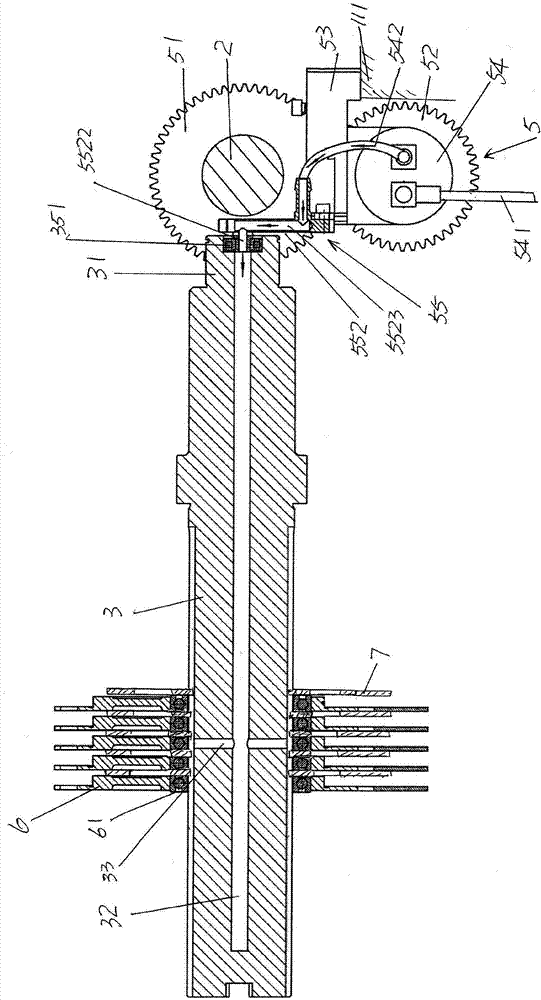

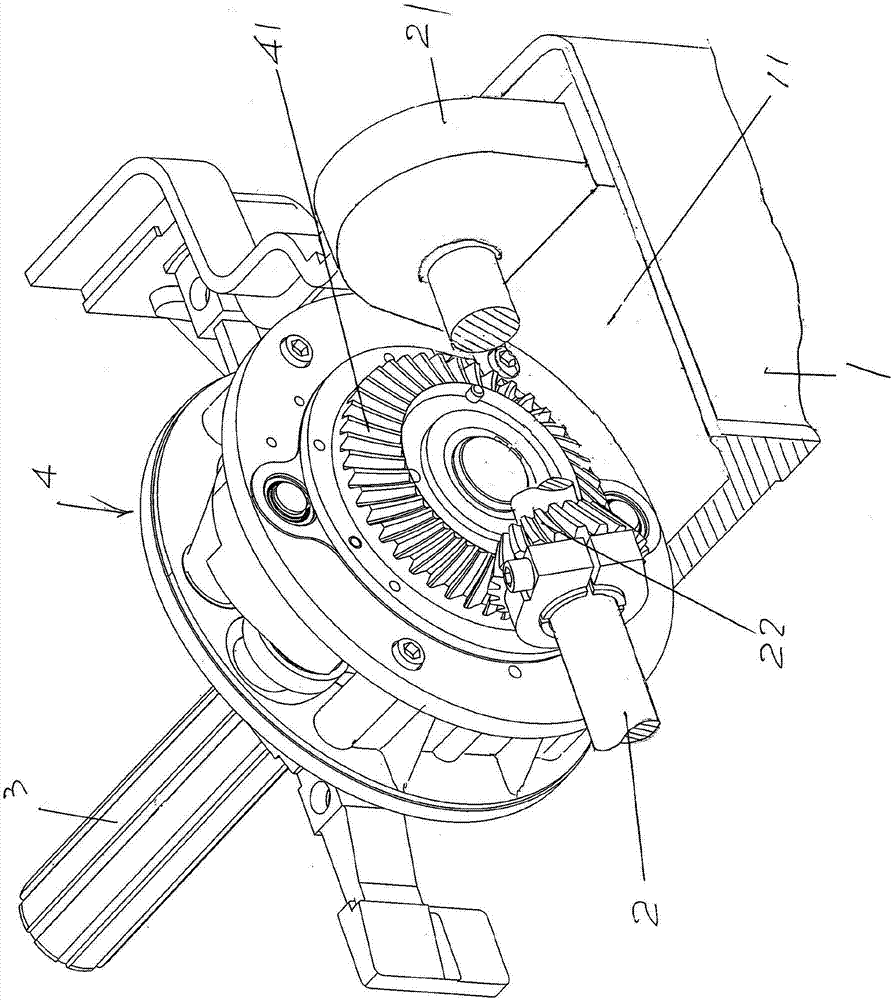

[0023] See figure 1 , shows the box body 1, the power input shaft 2, the spline shaft 3 and the cam transmission mechanism 4, the box body 1 is supported on the frame in the state of being vacated on the floor under the use state, and the right end of the power input shaft 2 is probed into the box cavity 11 of the box body 1 and rotatably supported on the power input shaft support seat 21 arranged in the box cavity 11, a power input shaft gear 22 is fixed at the right end of the power input shaft 2, and the power input shaft 2 The left end (not shown in the figure) is in transmission connection with the power input shaft drive device, the spline shaft 3 is located in the box cavity 11, and the front side of the cam transmission mechanism 4 is rotatably supported on the spline shaft head 31 of the spline shaft 3 , and the rear side of the cam transmission mechanism 4 is rotatably supported on the cam transmission mechanism supporting bearing seat 43 arranged in the casing cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com