Threaded sleeve provided with locking keys

A locking key and screw sleeve technology, applied in the direction of locking fasteners, screws, nuts, etc., can solve the problems of screw sleeve falling off, easy loosening, damage to the threaded hole of the part base body, etc., to achieve the effect of limiting and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the invention and are not intended to limit the scope of the present invention.

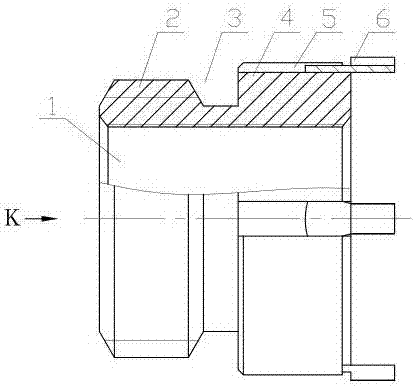

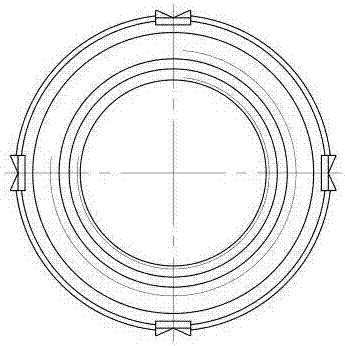

[0012] like figure 1 , figure 2 As shown, a screw sleeve with a locking key is composed of a screw sleeve body 1 with internal and external threads and 4 locking keys 6. The screw sleeve body 1 includes an integrally formed connecting part 2 and a locking part 4. The external thread is provided on the connecting part 2, and the internal thread runs through the connecting part 2 and the locking part 4; the outer circumference of the locking part 4 is provided with 4 evenly distributed dovetail-shaped keyways 5, and the dovetail-shaped A locking key 6 is inserted into the key groove 5 ; a tool relief groove 3 is provided in the outer circumferential direction between the connecting portion 2 and the locking portion 4 .

[0013] Further, after the locking ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com