flow adjustment valve

A technology of flow adjustment valve and flow change, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of obstructed flow, noise, large pressure loss, etc., and achieve the effect of reducing pressure loss and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

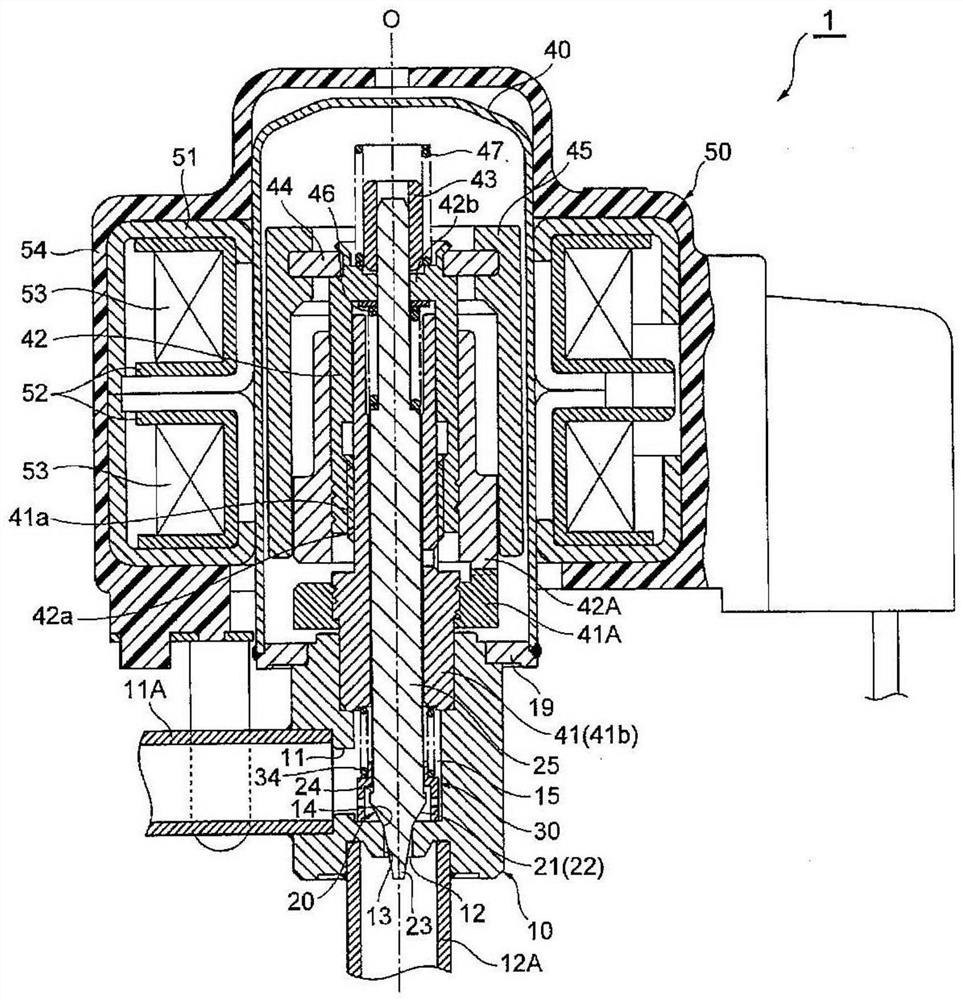

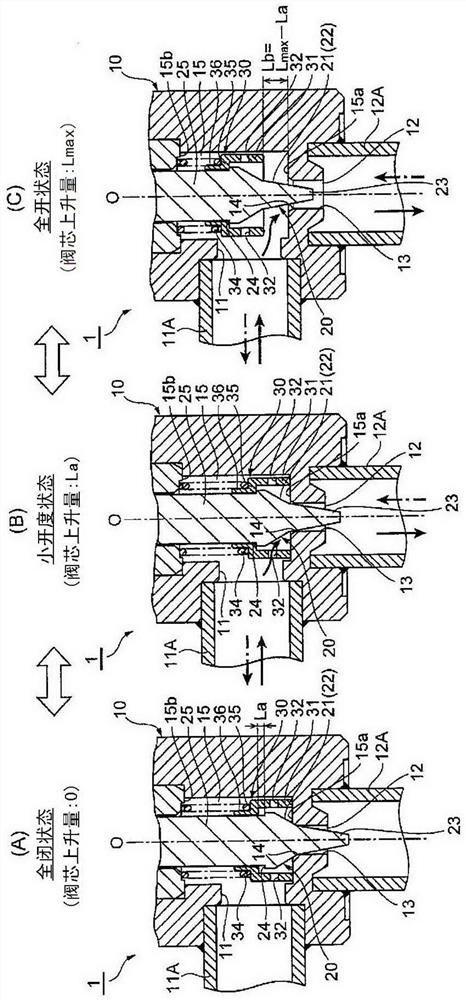

[0065] figure 1 is an overall cross-sectional view showing the first embodiment of the flow regulating valve according to the present invention, figure 2 It is a sectional view of main parts showing the main parts of the flow rate regulating valve according to the present invention in the first embodiment, figure 2 (A) is a diagram showing a fully closed state, figure 2 (B) is a diagram showing a state where the valve opening is small, figure 2 (C) is a diagram showing a fully opened state.

[0066] The flow rate regulating valve 1 of the illustrated embodiment is an electric valve for adjusting the flow rate of refrigerant used in, for example, a heat pump refrigeration and heating system. It is the same as the above-mentioned conventional electric valve. Basically, the flow rate regulating valve 1 has The valve main body 10 and the valve core 20, the valve main body 10 has a valve chamber 15 for introducing and exporting fluid (refrigerant) and a valve port 13 with a ...

no. 2 approach

[0086] Figure 4 It is a sectional view of main parts showing the main parts in the second embodiment of the flow rate regulating valve according to the present invention, Figure 4 (A) is a diagram showing a fully closed state, Figure 4 (B) is a diagram showing a state where the valve opening is small, Figure 4 (C) is a diagram showing a fully opened state.

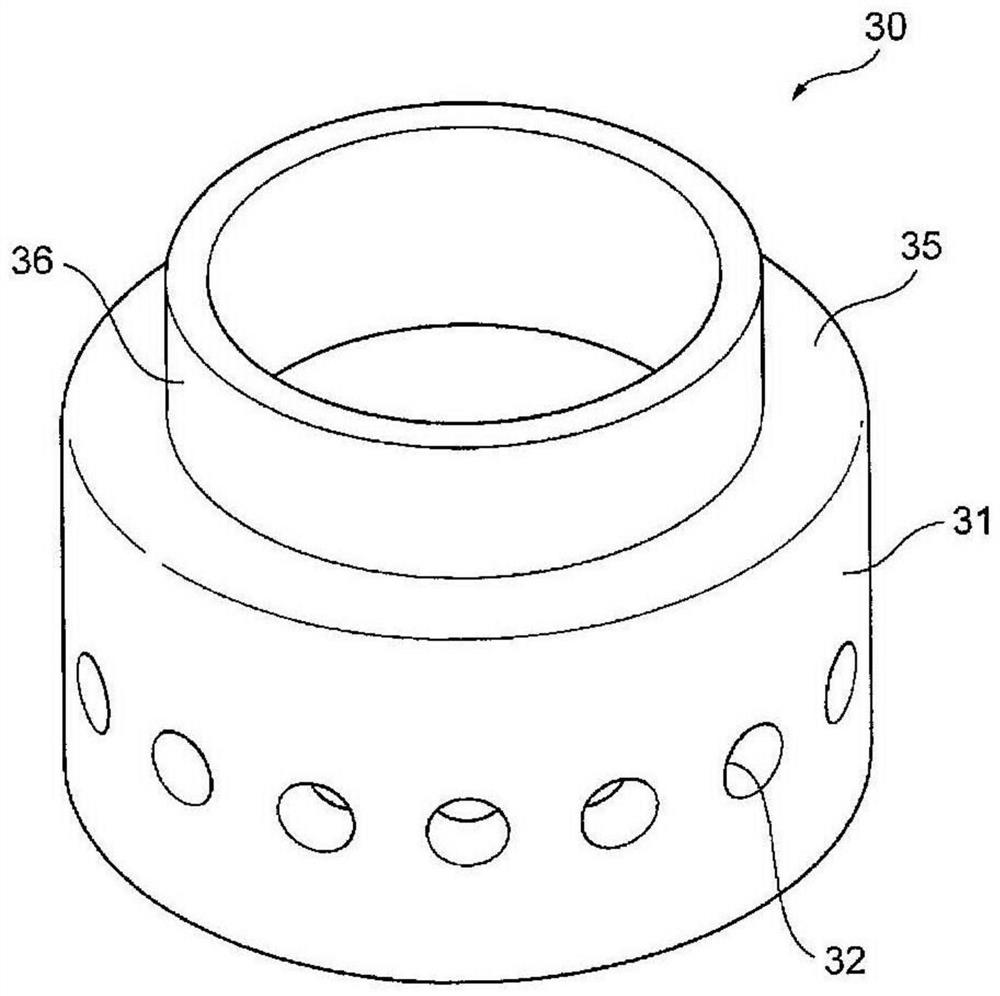

[0087] Basically, the structure of the noise reduction member 30 of the flow rate adjustment valve 2 of the second embodiment is different from the flow rate adjustment valve 1 of the above-mentioned first embodiment. Therefore, components having the same functions as those in the first embodiment are given the same reference numerals and their detailed descriptions are omitted, and only the points of difference will be described in detail below.

[0088] In the flow rate regulating valve 2 of this embodiment, the cylindrical body 31 and the cover body 35 constituting the noise reduction member 30 are formed as sepa...

no. 3 approach

[0098] Figure 5 is a cross-sectional view of main parts showing a third embodiment of a flow rate regulating valve according to the present invention, Figure 5 (A) is a diagram showing a fully closed state, Figure 5 (B) is a diagram showing a state where the valve opening is small, Figure 5 (C) is a diagram showing a fully opened state.

[0099] Basically, the flow rate control valve 3 of the third embodiment is different in structure surrounding the valve port 13 from the flow rate control valve 2 of the second embodiment described above. Therefore, components having the same functions as those in the second embodiment are assigned the same reference numerals and their detailed descriptions are omitted, and only the points of difference will be described in detail below.

[0100] In the flow control valve 3 of the present embodiment, the cylindrical body 31 and the lid body 35 constituting the noise reduction member 30 are removed, and the compression coil spring 34 bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com