Sampling trolley with detachable tray

A tray and trolley technology, applied in the field of sampling trolleys with detachable trays, can solve the problems of inconvenient sampling bottles, excessive bottom sampling of raw material barrels, difficult loading, etc., to achieve easy operation, easy bottom sampling, and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments.

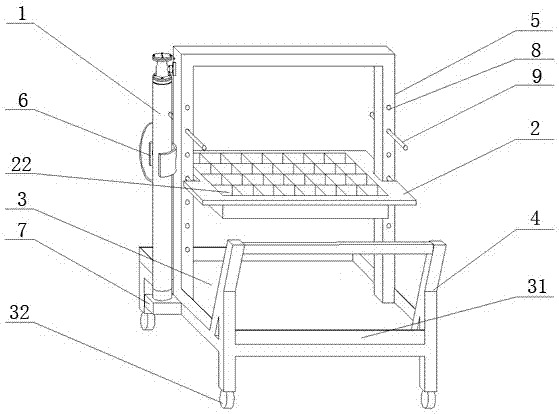

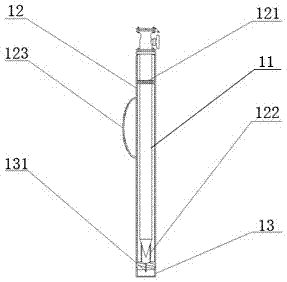

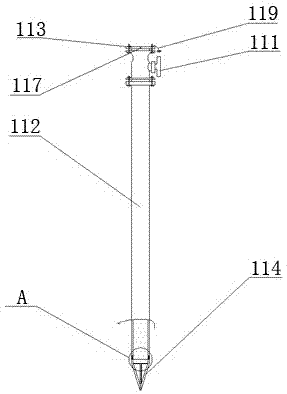

[0024] As shown in the figure: the embodiment of the present invention provides a sampling trolley with a detachable tray, including a car body, a sampler 1 and a tray 2, and the car body includes a bottom plate 3 provided with wheels 32 and a U-shaped support frame 5. The U-shaped support frame 5 is opened downwardly and vertically arranged on the bottom plate 3. The bottom plate 3 is also provided with a handle 4, the U-shaped support frame 5 is composed of two vertical arms and a horizontal arm, and the U-shaped support frame A ferrule 6 is fixedly provided on the outer side of one of the vertical arms of 5, and the ferrule 6 has a C-shaped structure. After the sampler 1 is clamped in the C-shaped structure, a support for the sampler 1 is provided at the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com