Connector adapting structure

A connector, elastic contact technology, applied in the direction of connection, parts of the connection device, contact parts, etc., can solve the problems of user inconvenience, structural damage, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to achieve the above-mentioned purpose and effect, the technical means and the structure adopted by the present invention are hereby described in detail with respect to the preferred embodiments of the present invention.

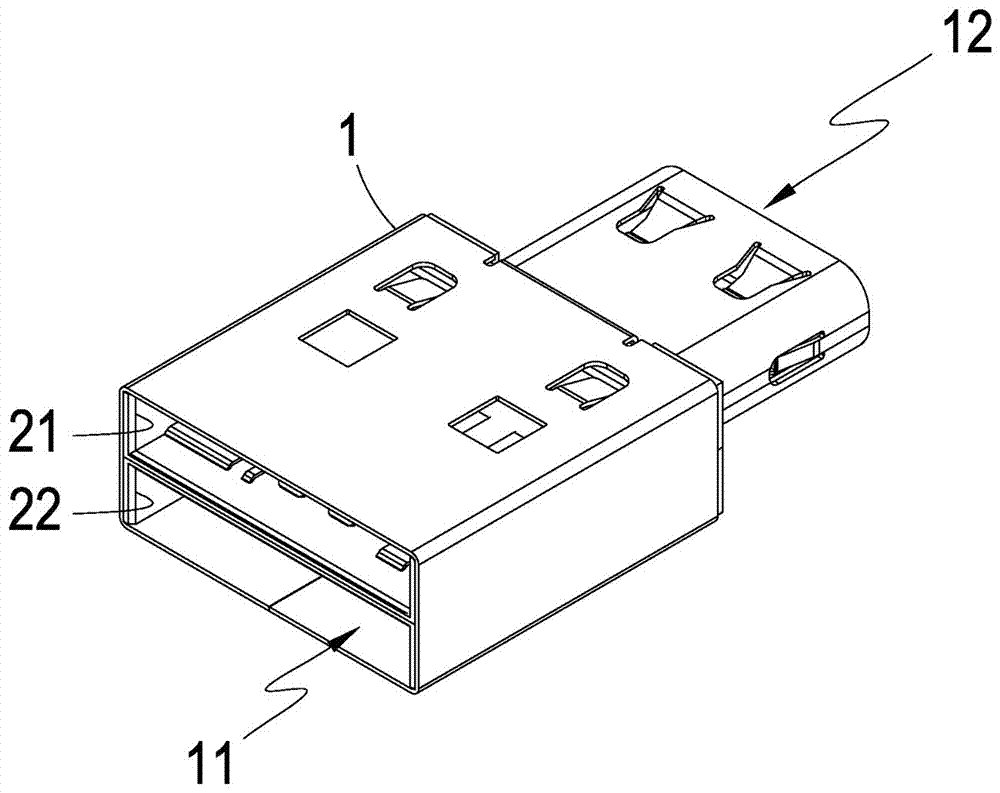

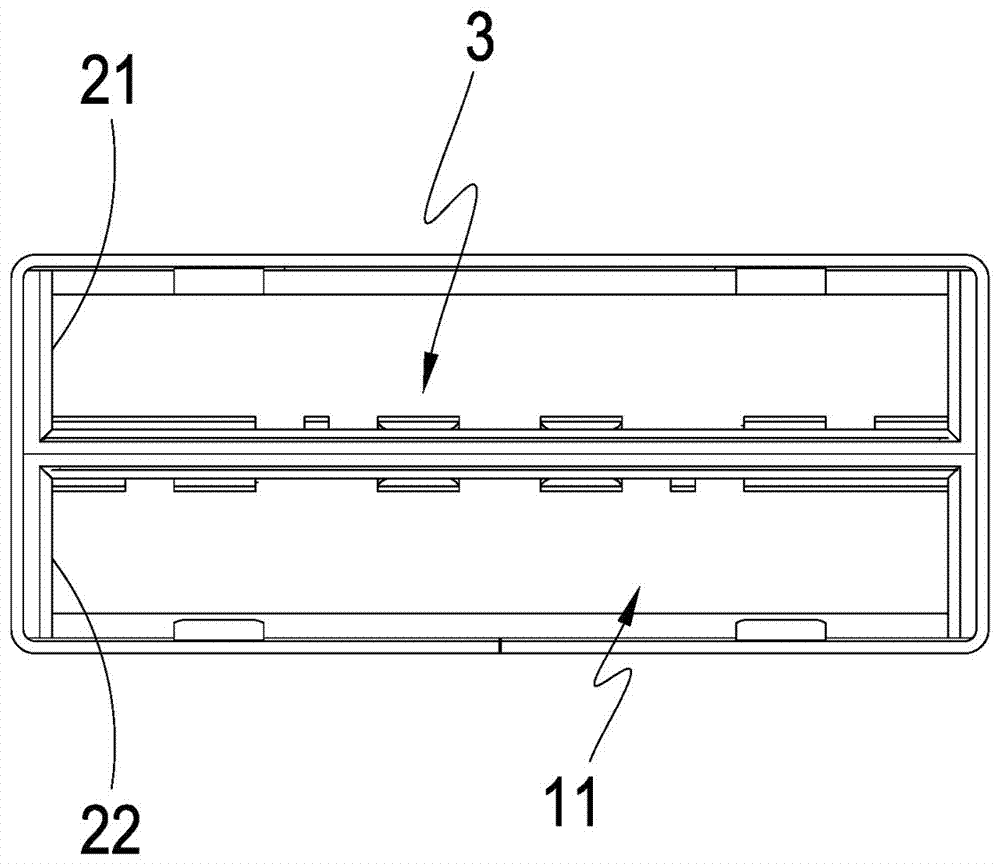

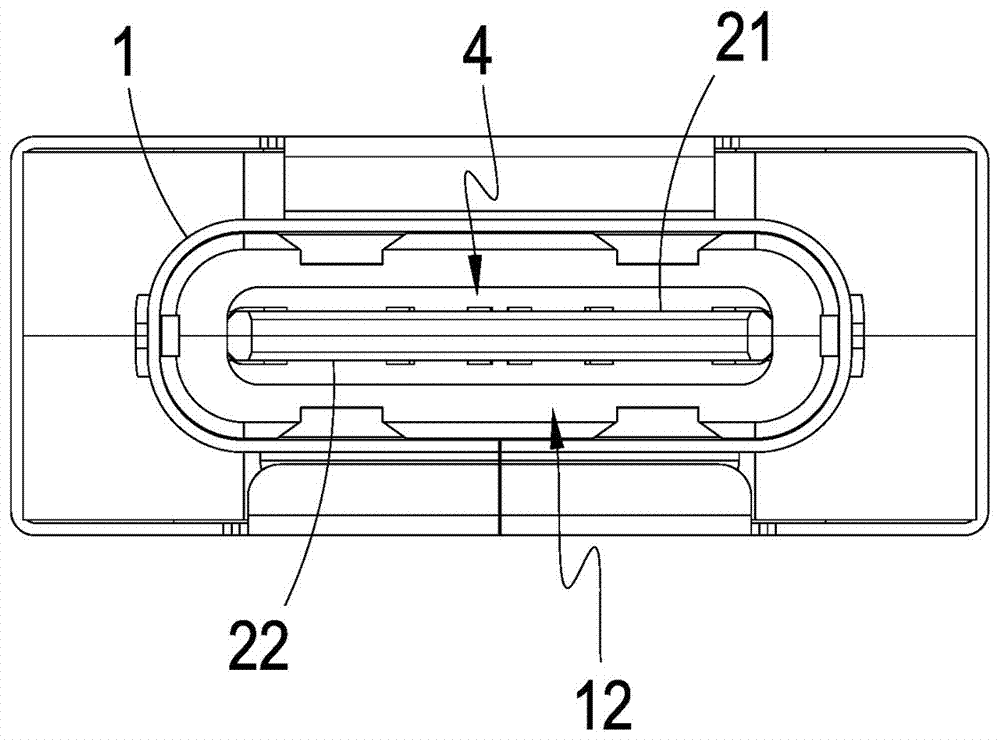

[0053] see figure 1 , figure 2 , image 3 and Figure 4 As shown, it is a perspective view, a front view, a rear view and a perspective view of the second transmission conductor group of a preferred embodiment of the present invention. It can be clearly seen that the present invention includes:

[0054] A shielding shell 1, the shielding shell 1 includes a male end opening 11, and a female seat opening 12 whose opening direction is away from the male end opening 11;

[0055] a first insulating colloid 21 accommodated in the shielding shell 1;

[0056] a second insulating colloid 22 accommodated in the shielding shell 1 and located on one side of the first insulating colloid 21;

[0057] a plurality of first transmission conductor groups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com