Standalone force/torque sensor assembly for force-controlled robots

A torque sensor, robot technology, applied in robots, surgical robots, general control systems, etc., can solve problems such as damage to force/torque sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

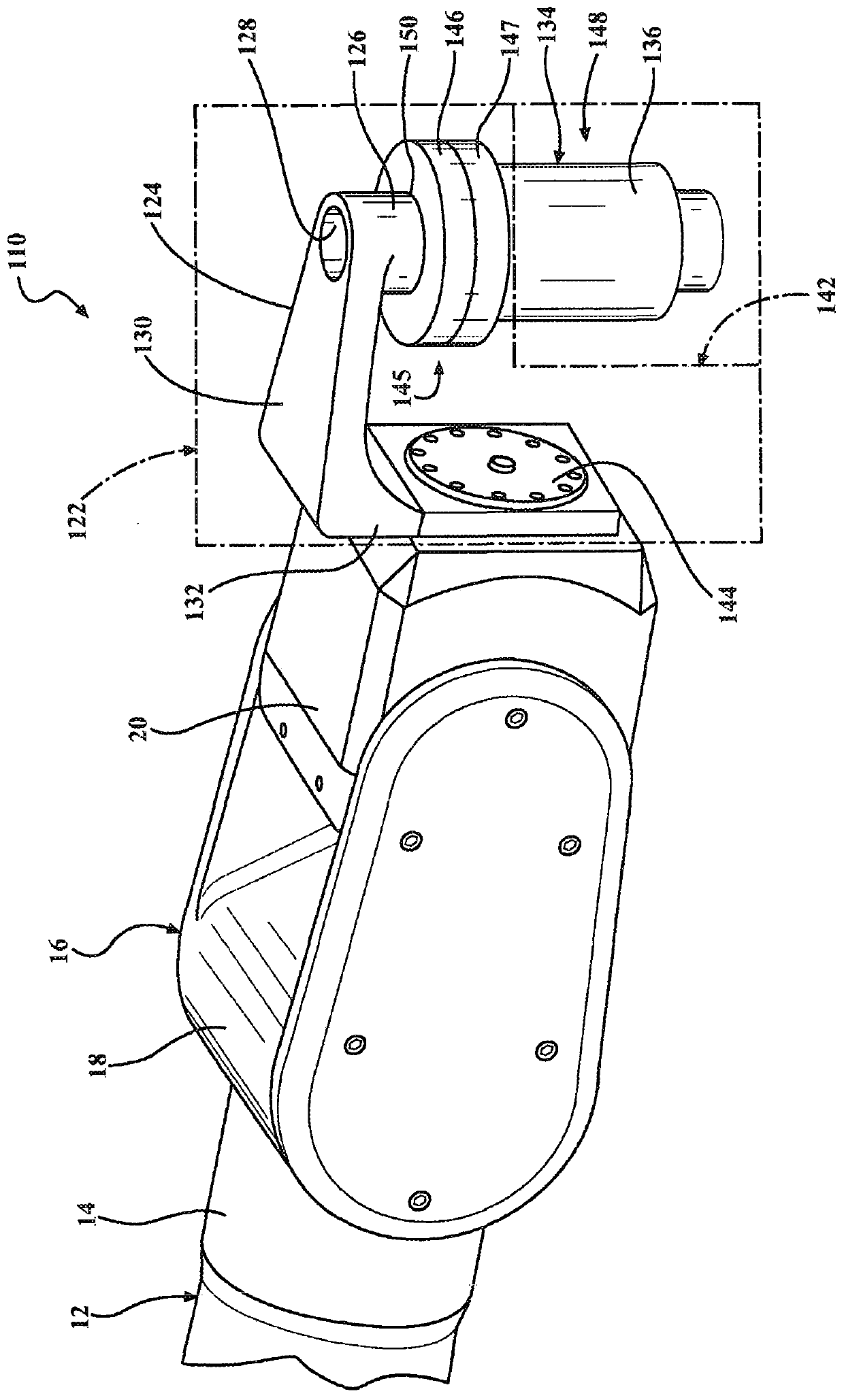

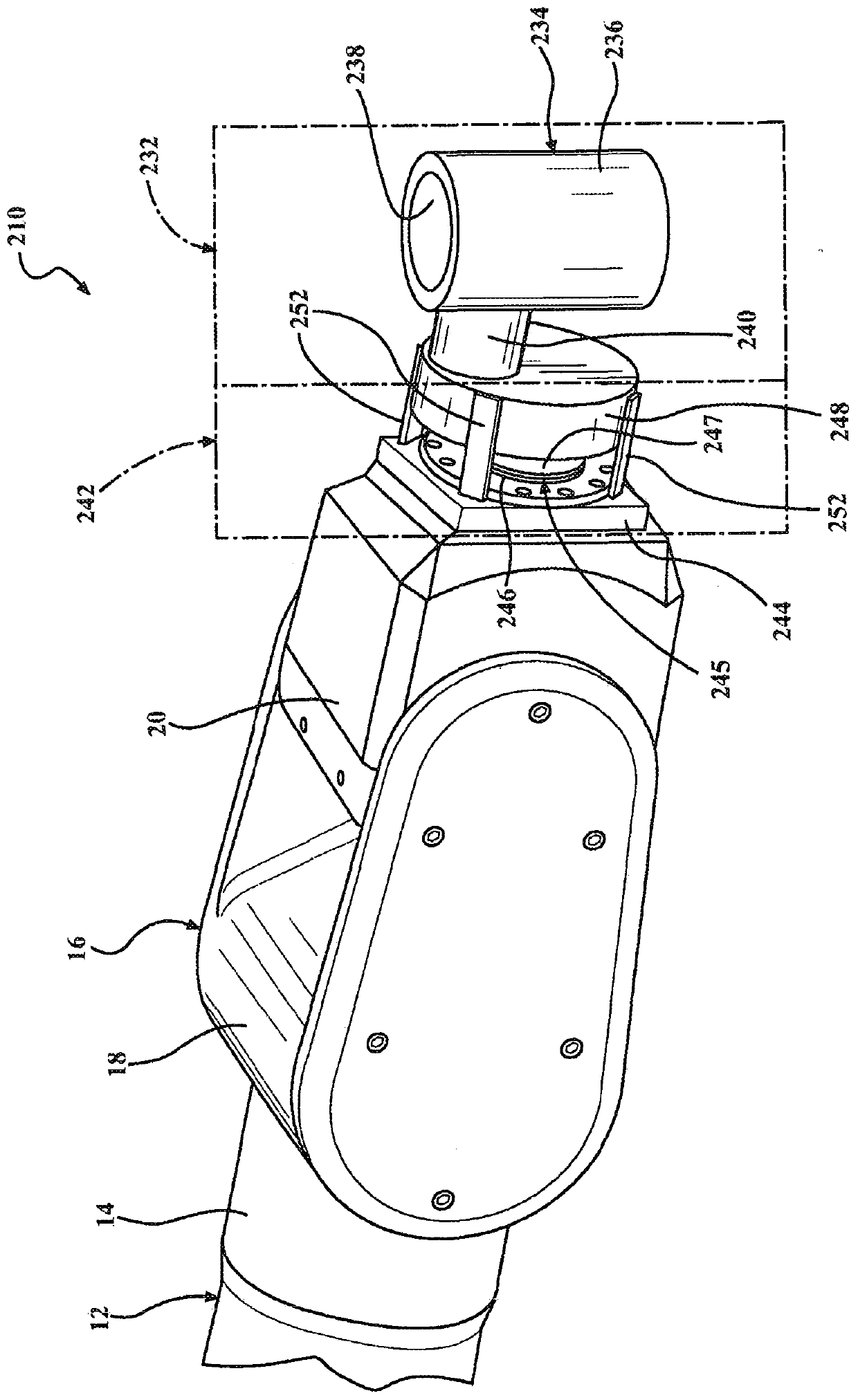

[0017] Referring to the accompanying drawings, especially figure 1 , is shown in operative relationship to a robot (generally designated 12 ) one embodiment of a self-contained torque / force sensor assembly 10 according to the present invention. In one embodiment, the robot 12 is of the force-controlled type and includes a robot arm 14 extending from a body of the robot 12 (not shown). The robot 12 also includes a wrist joint (generally designated 16 ) attached to the end of the robot's arm 14 . In this embodiment, the wrist joint 16 includes a bracket 18 attached to the arm 14 of the robot. The bracket 18 is generally "U" shaped. The wrist joint 16 also includes a flange 20 pivotally connected to the bracket 18 . Flange 20 is generally rectangular, but may be of any suitable shape. Flange 20 is disposed in an opening of bracket 18 and is pivotally connected to bracket 18 by a suitable mechanism, such as a pin (not shown). It should be understood that the flange 20 pivots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com