Axle unit

A technology of components and axle tubes, applied in the field of axle units of commercial vehicles, can solve the problems of large size and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

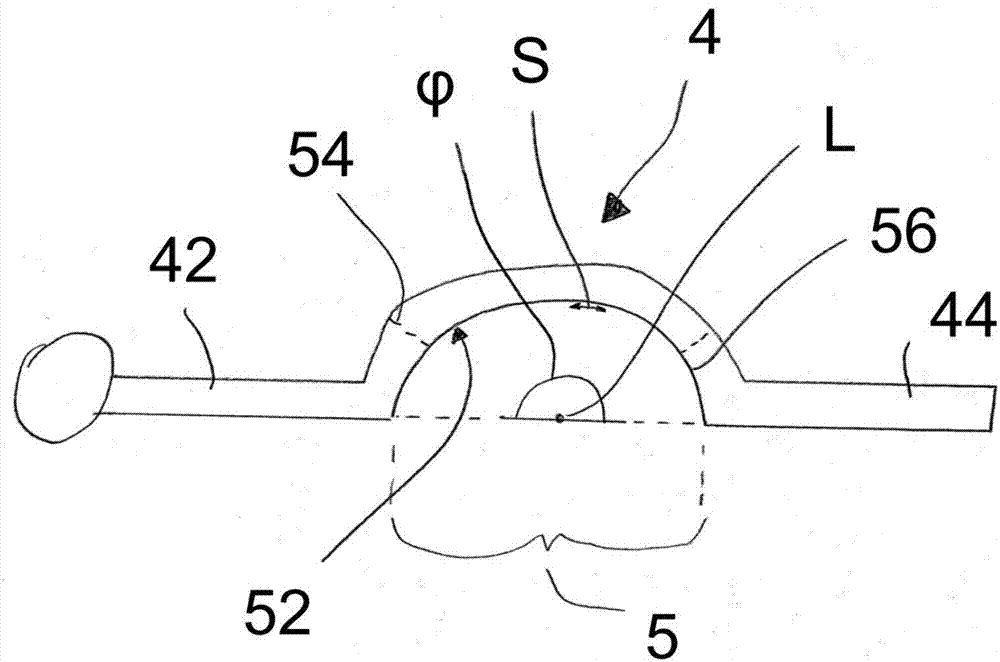

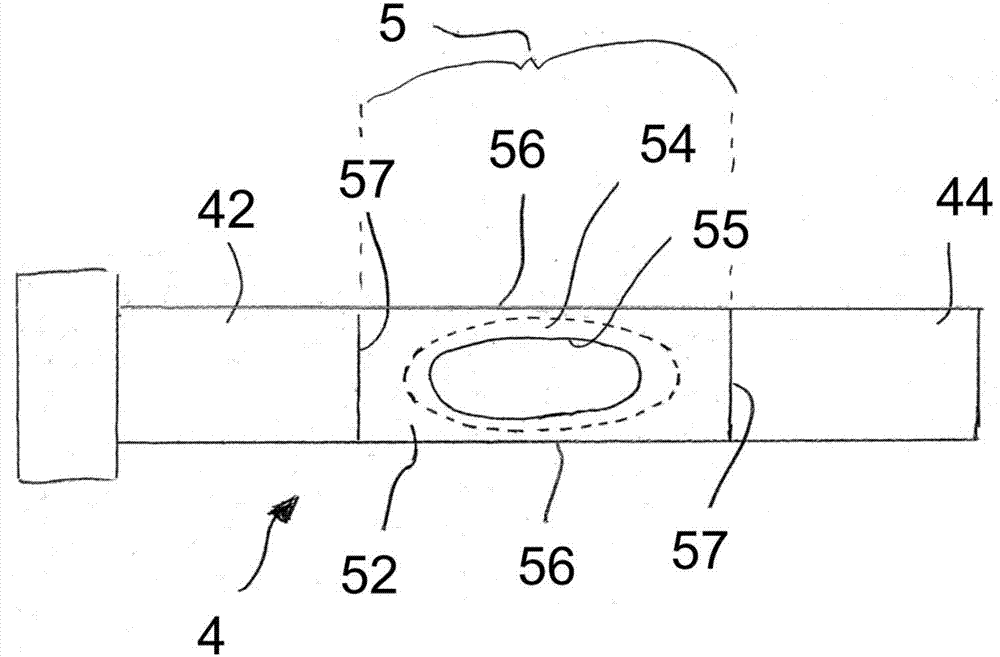

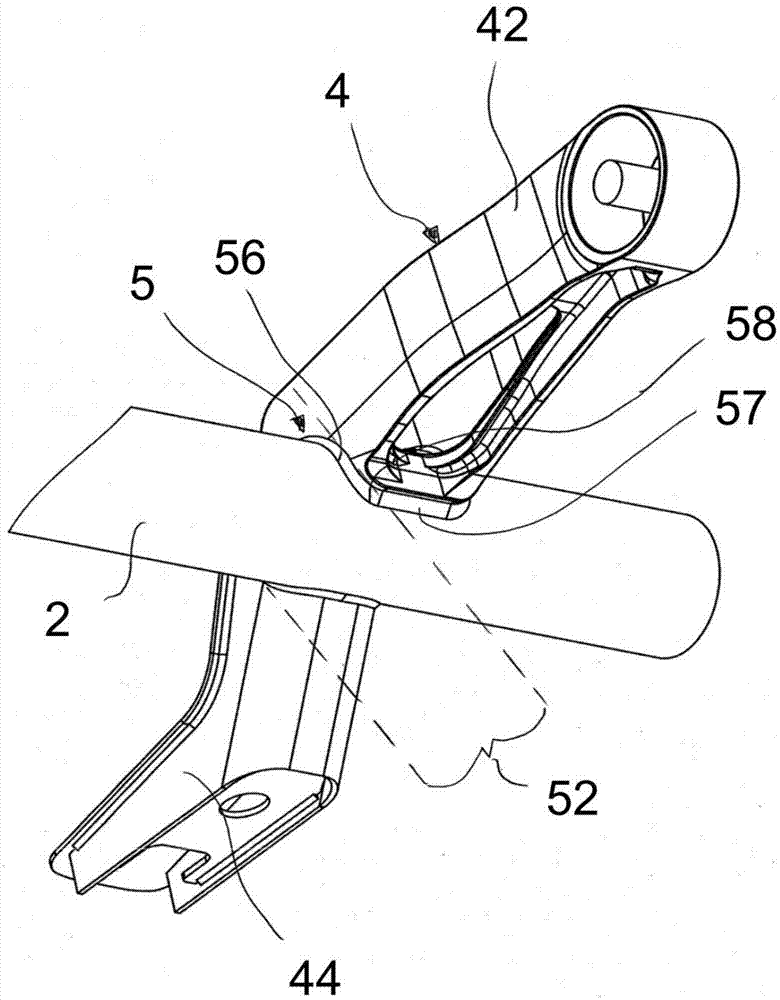

[0026] figure 1 Shows a side view of a preferred embodiment of a linkage element 4 according to the invention with an arm 42 on the left, a joint 5 adjacent to the arm 42 and a support adjacent to the joint 5 Section 44. On the left side of the arm 42 is schematically shown a bearing eye at which the link element is pivotably connected to the frame of the vehicle, in particular a commercial vehicle. The joint 5 of the linkage element 4 preferably has a first weld 52 which preferably has a lateral seam 56 . It cannot be seen in the figures that the second lateral seam 56 is arranged on the side of the linkage element 4 facing away from the viewer. The link element 4 is welded to the axle tube 2 (not shown) at the lateral seam 56 . exist figure 1 In the illustrated embodiment, the lateral seam 56 is here at an arc angle with respect to the connecting rod axis L Extended, in this example, the arc angle is slightly greater than 180°. Additionally, the side seam 56 has a sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com