Capacitors for multilayer printed circuit boards

A multi-layer printing and capacitor technology, applied in the field of capacitors, can solve problems such as difficult decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

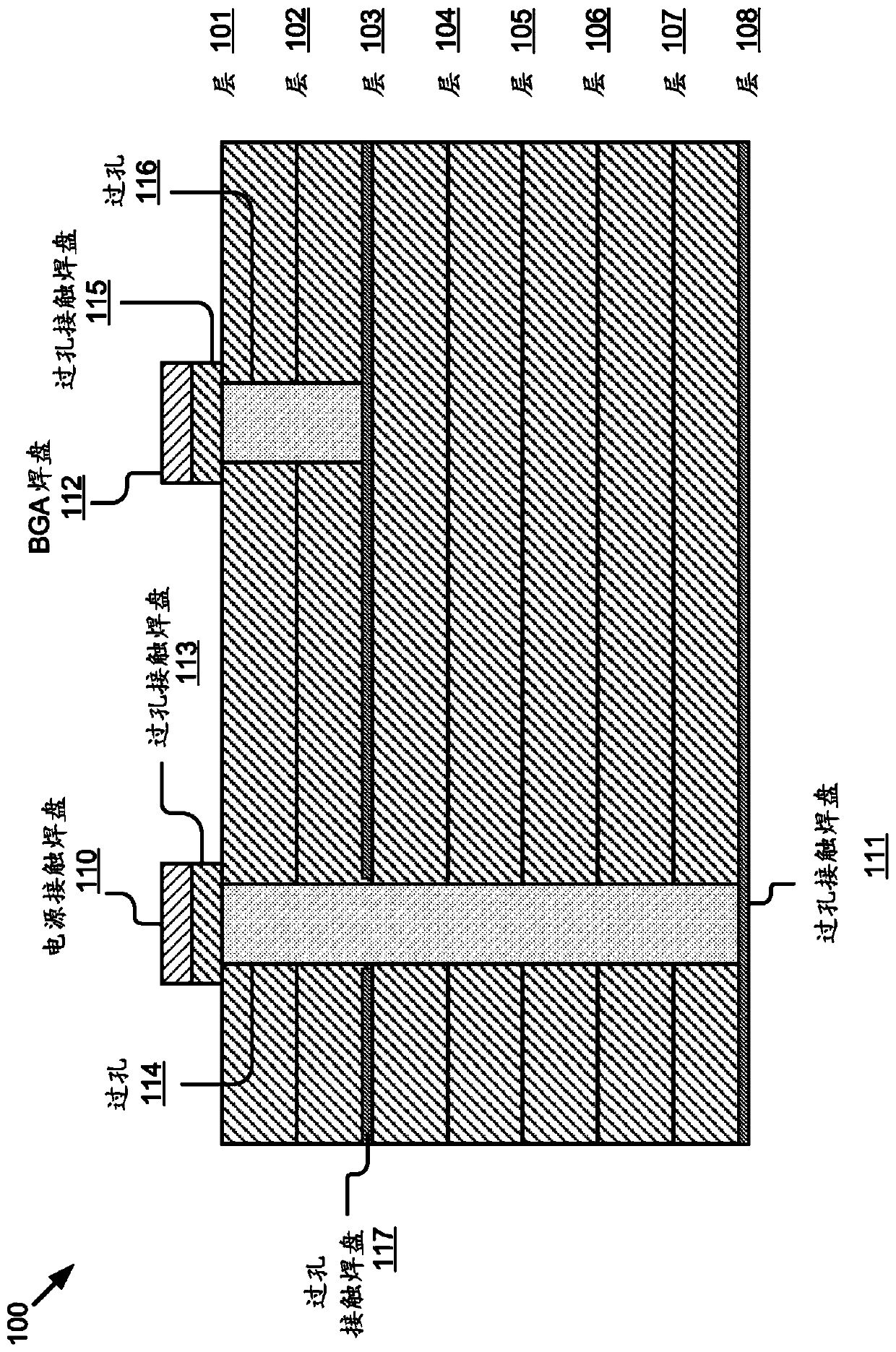

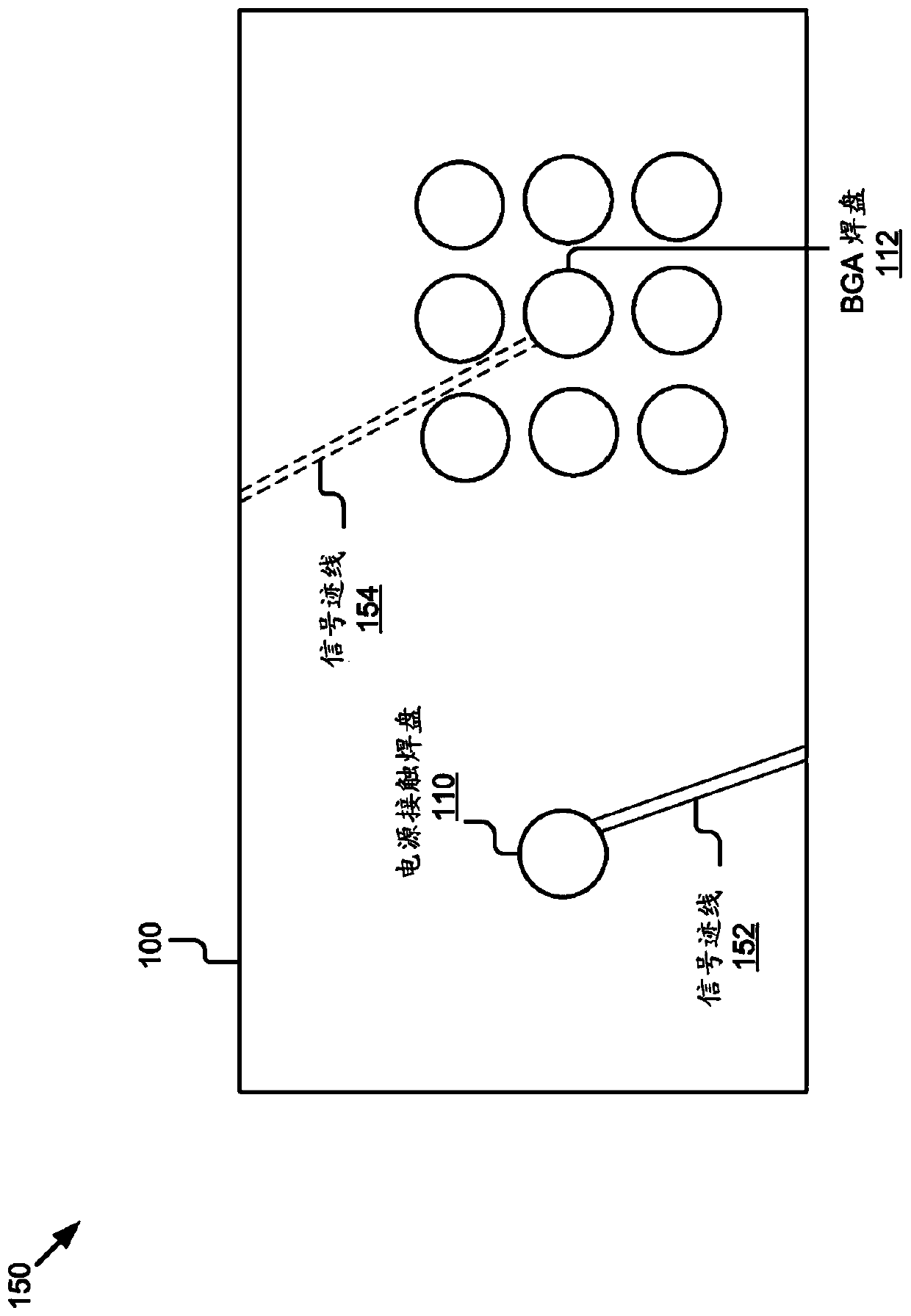

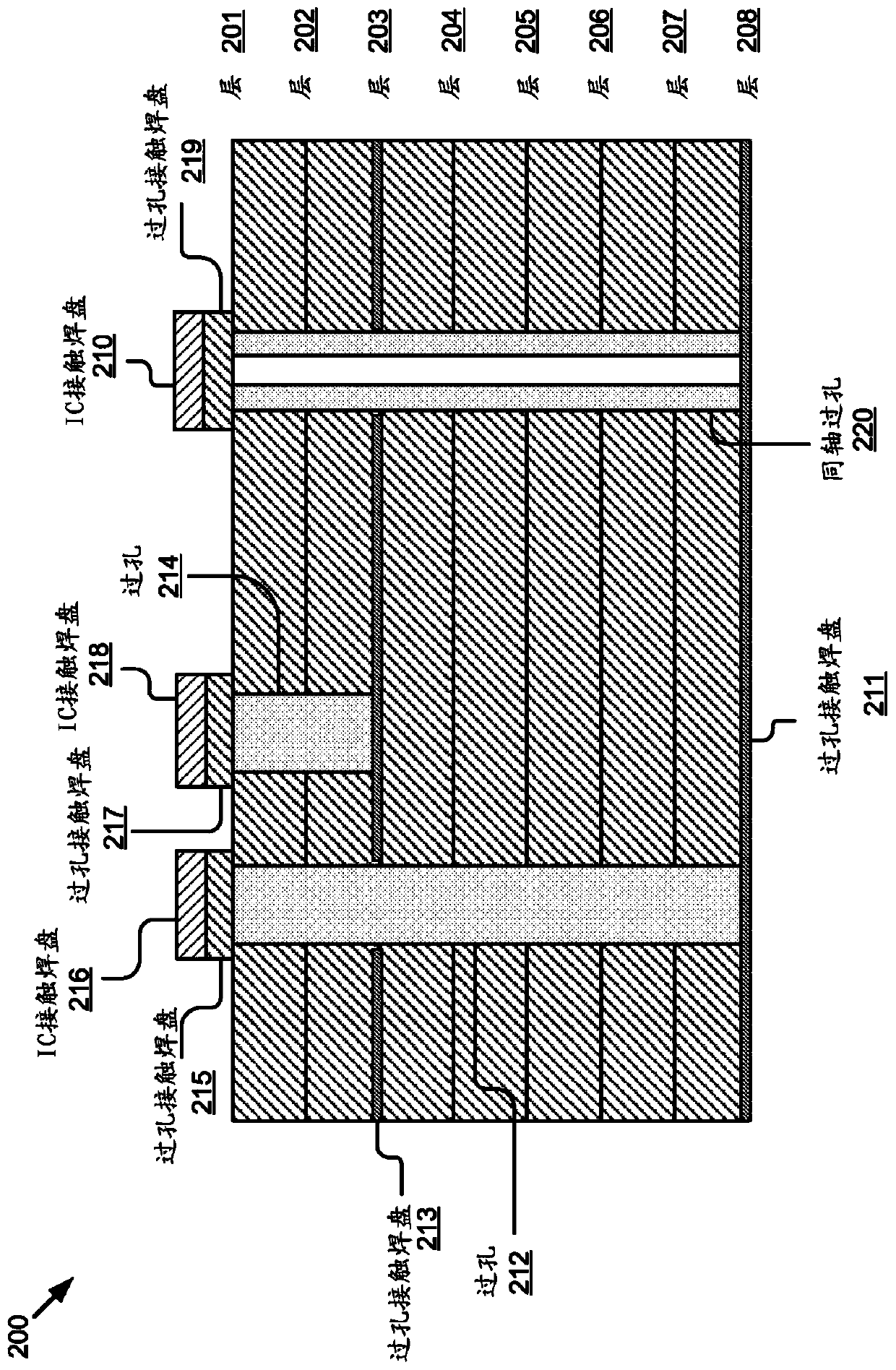

[0018] Embodiments described herein relate generally to capacitors for printed circuit boards.

[0019] Some embodiments described herein may include via-in-pad capacitors that may be included in rigid or flex PCBs for high frequency applications. For example, capacitors can be charged and / or discharged quickly and can be implemented in applications at 25GHz or higher. In another example, capacitors may be implemented in 56GHz or higher frequency applications. Under-pad via capacitors can be placed directly below the IC contact nodes, which eliminates contact resistance, reduces ESR and ESL, and eliminates area factor compared to parallel plate capacitors and / or printed capacitors. Via under pad capacitors may have a high self-resonant frequency compared to parallel plate capacitors and / or printed capacitors.

[0020] In some implementations, an under-pad via capacitor may include a via disposed directly under an IC contact pad and a dielectric compound filled in the via. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com