Positioning orthopedic equipment

A technology for equipment and shaping plates, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve the problems of poor product component consistency, poor product consistency, low positioning accuracy, etc., to avoid poor positioning accuracy and good consistency. , the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0034] The orientations involved in this manual are all based on the orientation of the positioning and shaping device of the present invention when it is working normally, and are not limited to its orientation during storage and transportation, and only represent relative positional relationships, not absolute positional relationships.

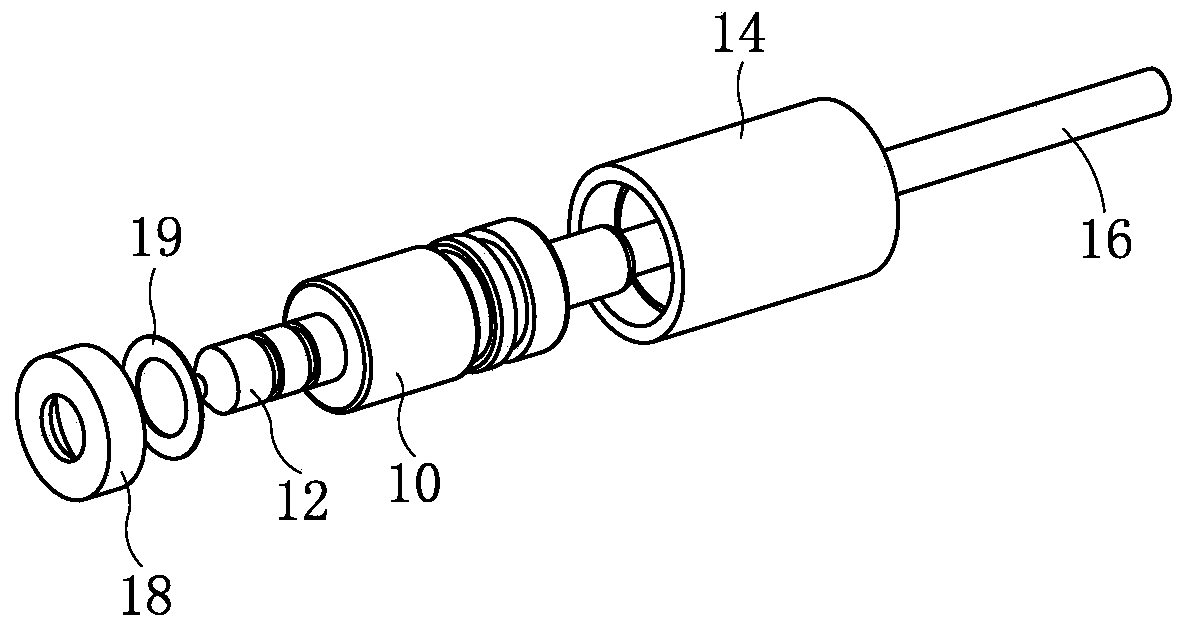

[0035] figure 1 The product shown is a bushing-type pin product, which includes a female pin seat 10, pins 12 and wires 16 connected to both ends of the female pin seat 10, and also includes a socket that is bonded and fixed on the female pin seat 10. The washer 18 at one end of the needle 12 and the sleeve 14 sleeved on the outside of the pin female seat 10 are assembled as follows: the washer 18 is bonded to the end of the pin female seat 10 through double-sided adhesive 19, and then the washer 18 is Reshaping, after the reshap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com