Welding device

A technology for welding devices and welding components, applied in the direction of electric heating devices, auxiliary devices, welding equipment, etc., can solve problems such as difficulty in taking into account the fixation of welding parts, lower production efficiency and product qualification rate, and lack of rotary welding machines, etc., to achieve Improve welding efficiency and welding accuracy, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

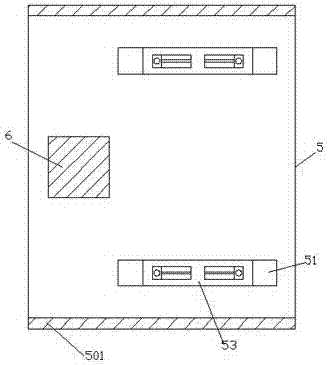

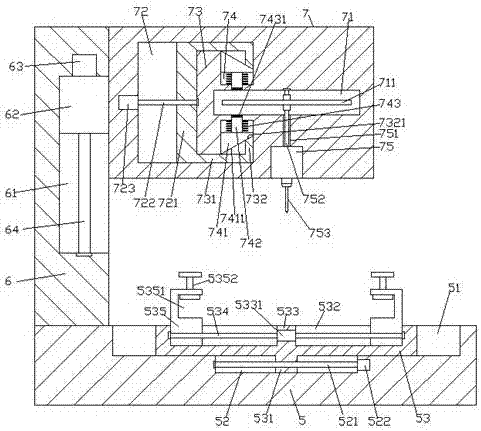

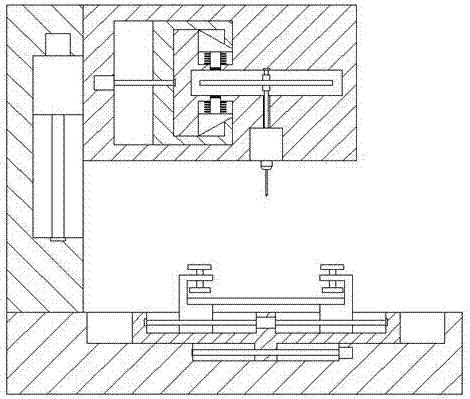

[0022] like Figure 1-Figure 5 As shown, a welding device of the present invention includes a base 5 and a welding assembly 7 arranged above the top of the base 5, a column 6 is provided on the top surface of the left side of the base 5, and the base 5 A first chute 51 is correspondingly arranged in the front and rear of the top surface of the left side, and a second chute 52 is arranged at the midpoint of the inner bottom surface of each of the first chute 51. The first screw rod 521, the first sliding block 53 is slidably connected in the first sliding groove 51, the welding assembly 7 is provided with a sliding cavity 72, and the right side of the sliding cavity 72 is provided with a bump 73 , the bump 73 is provided with a locking cavity 71 extending to the right side, the bottom surface of the welding assembly 7 is fixedly provided with a welding electric rotating machine 75, and the bottom of the welding electric rotating machine 75 is matched with a welding head 753. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com