One-mould double-cavity door foaming mould

A foaming mold with one mold and two cavities, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of waste of fixture space and low production efficiency, and achieve the goal of reducing input costs and increasing foaming production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

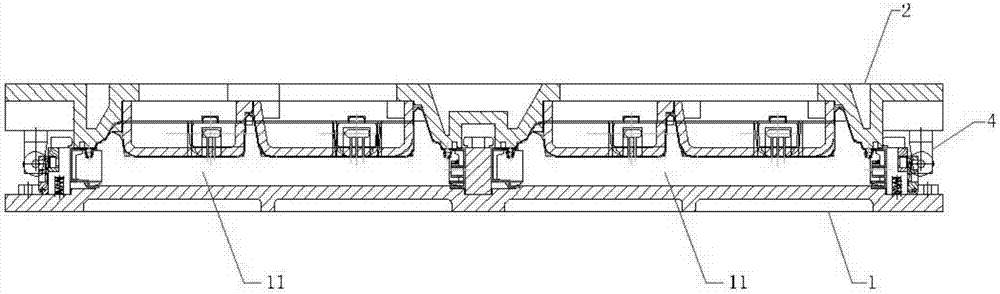

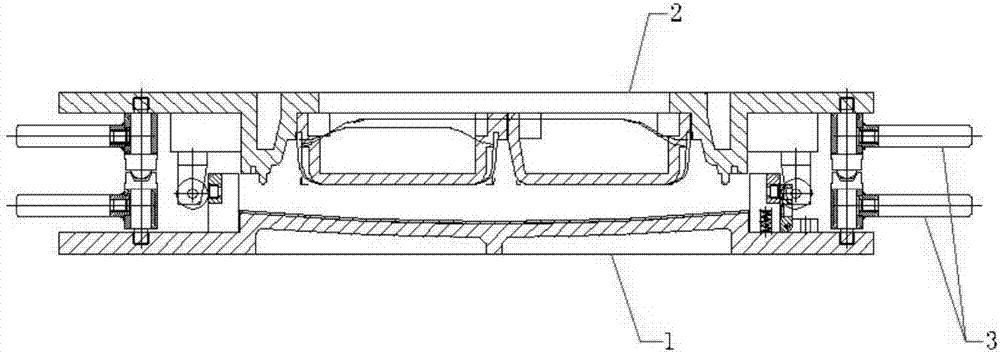

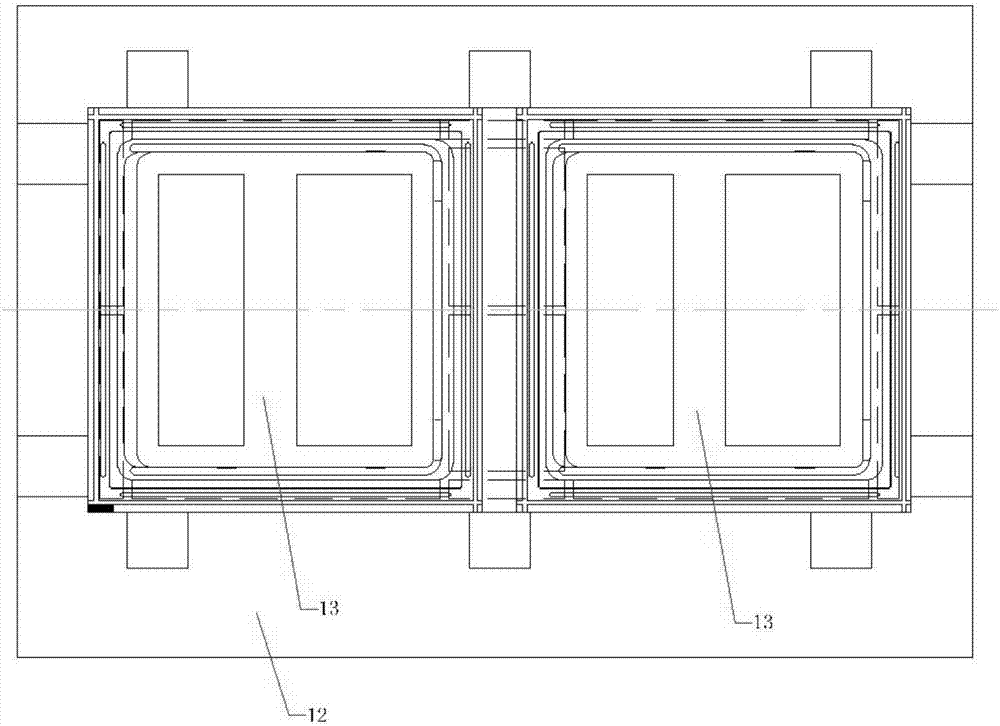

[0033] see Figure 1a , Figure 1b , the one-mode double-cavity door body foaming mold of the present embodiment includes:

[0034] Lower die assembly 1, such as Figure 3a , Figure 3b Shown, be that the intermediate baffle plate 6 is fixedly arranged in the middle part of the lower template 5, and the front baffle plate 7, the rear baffle plate 8, the left baffle plate 9 and the right baffle plate are respectively arranged on the front, rear, left and right sides of the intermediate baffle plate 6. 10. Form two symmetrical mold cavities 11 with the middle baffle 6 as the boundary, the lower end of the rear baffle 8 is fixedly arranged on the upper end of the lower template 5, and the lower ends of the front baffle 7, the left baffle 9 and the right baffle 10 are respectively The activity is set on the upper end of the lower template 5;

[0035] Upper die assembly 2, such as Figure 2a , Figure 2b , Figure 2c As shown, two upper mold cores 13 are symmetrically fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com