Feeding mechanism for solvent type circuit board cleaning machine for high temperature resistant diodes

A diode and solvent-based technology is used in the field of feeding mechanisms for high-temperature diode solvent-based circuit board cleaning machines, which can solve the problems of human health injury, lack of safety, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

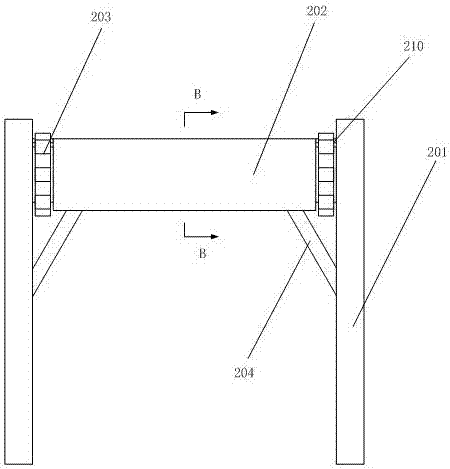

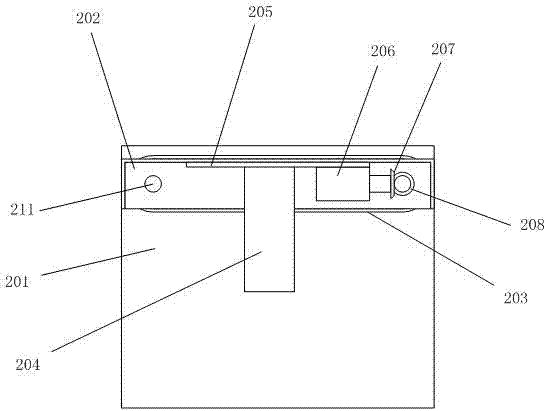

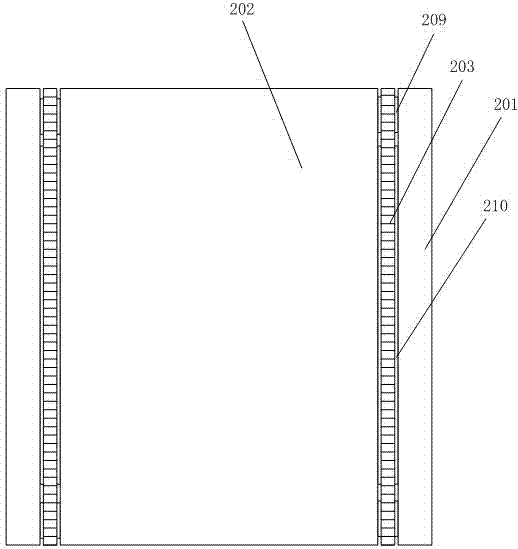

[0019] Such as Figure 1-5 As shown, the feeding mechanism for the high-temperature-resistant diode solvent-type circuit board cleaning machine provided by the invention includes: a conveying mechanism and a transfer mechanism installed above the conveying mechanism;

[0020] Wherein, the conveying mechanism includes two supporting side plates 201, a supporting case 202, two conveying chains 203, a conveying drive motor 206, and two driving shafts 211; the two driving shafts 211 run through the supporting case 202 and are installed in parallel Between the two support side plates 201; at both ends of the drive shaft 211 and between the support side plate 201 and the support case 202, there is a drive gear 209; two conveyor chains 203 are respectively wrapped around the two drive shafts 211 On the two drive gears 209 at the end; the height of the upper edge of the support side plate 201 is greater than the height of the upper edge of the conveyor chain 203; the height of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com