Pneumatic diaphragm pump with external pneumatic control valve

A technology of pneumatic diaphragm pumps and air control valves, which is applied to pumps with flexible working elements, pumps, machines/engines, etc., can solve the problems of troublesome disassembly and maintenance, high cost, high cost of use, etc., to reduce the number of accessories and use The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

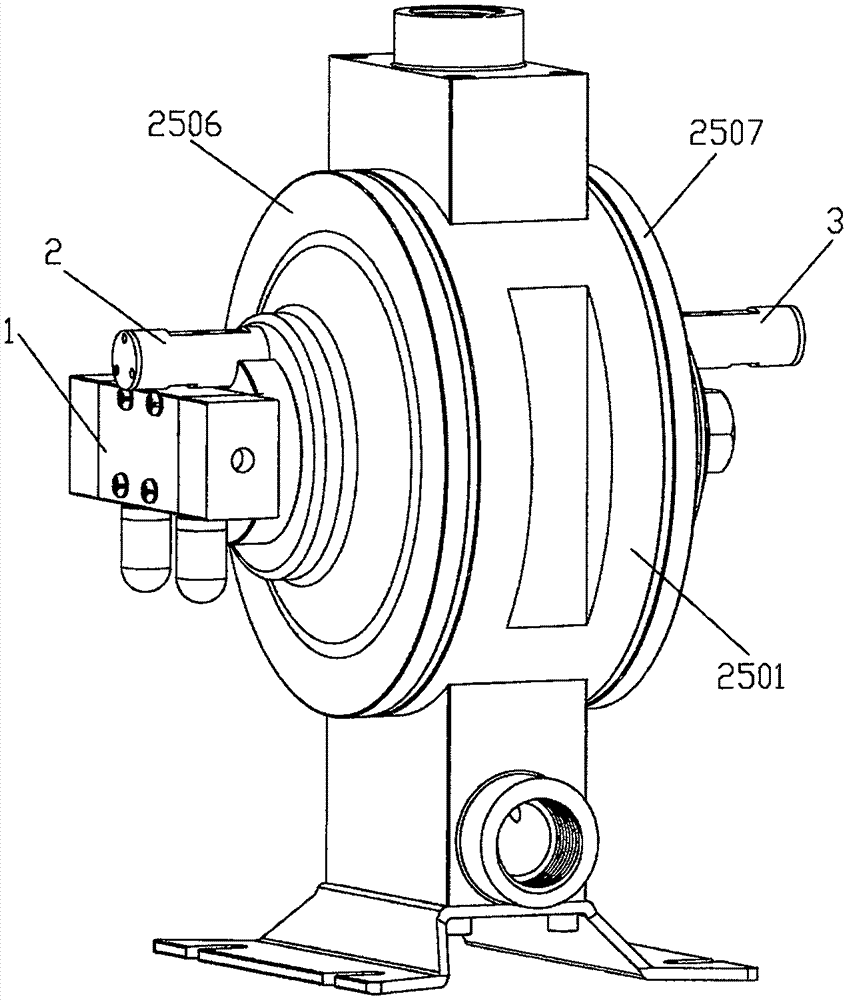

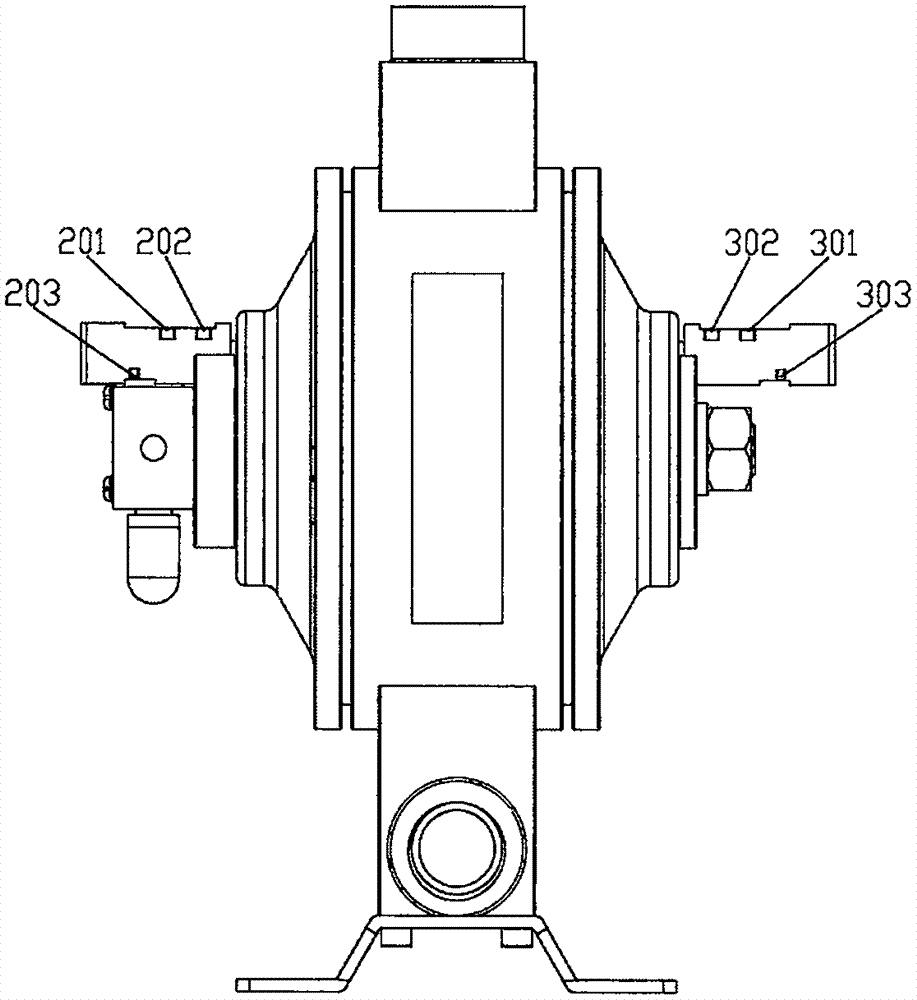

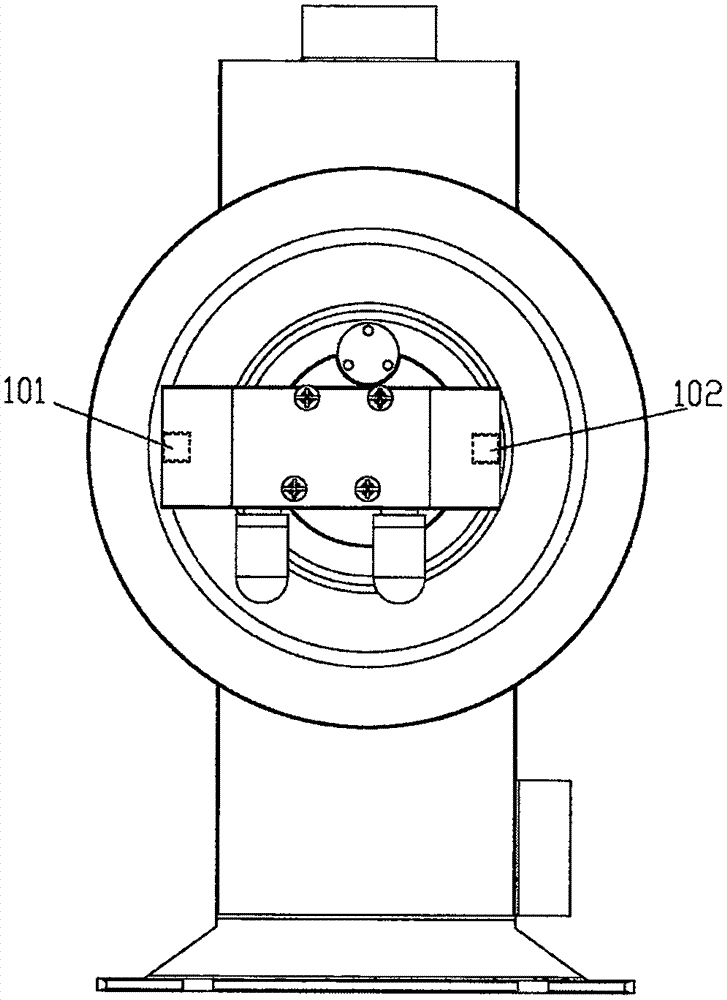

[0019] like Figure 1 to Figure 5 As shown, a pneumatic diaphragm pump with an external air control valve provided by the present invention includes an air control valve 1, a pump body 2501, a central shaft 2517, a left cover 2506, a right cover 2507, a reversing switch 2, and a reversing switch 2 3. There is a U-shaped hole in the center of the pump body 2501, and a diaphragm push rod 2519 is installed in the U-shaped hole to pass through the U-shaped hole across the pump body 2501. The U-shaped hole of the pump body 2501 and A sealing ring 2524 is installed between the diaphragm push rods 2519 to seal the pump body 2501 and the diaphragm push rod 2519; A diaphragm 2516 is respectively installed between the right cover 2507 and the pump body 2501 to divide the left cover 2506, the pump body 2501, and the right cover 2507 into an air cavity and a fluid cavity; The two ends of the push rod 2519 are connected and fixed through the diaphragm inner protection block 2515, the diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com