Permanent magnet mounting automatic machine of external rotor brushless direct current motor

A technology of brushed DC motors and permanent magnets, which is applied in the manufacture of stator/rotor bodies, electromechanical devices, electric components, etc., can solve the problems of reliability and pasting quality, and achieve compact structure, convenient assembly and disassembly, fast assembly and The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

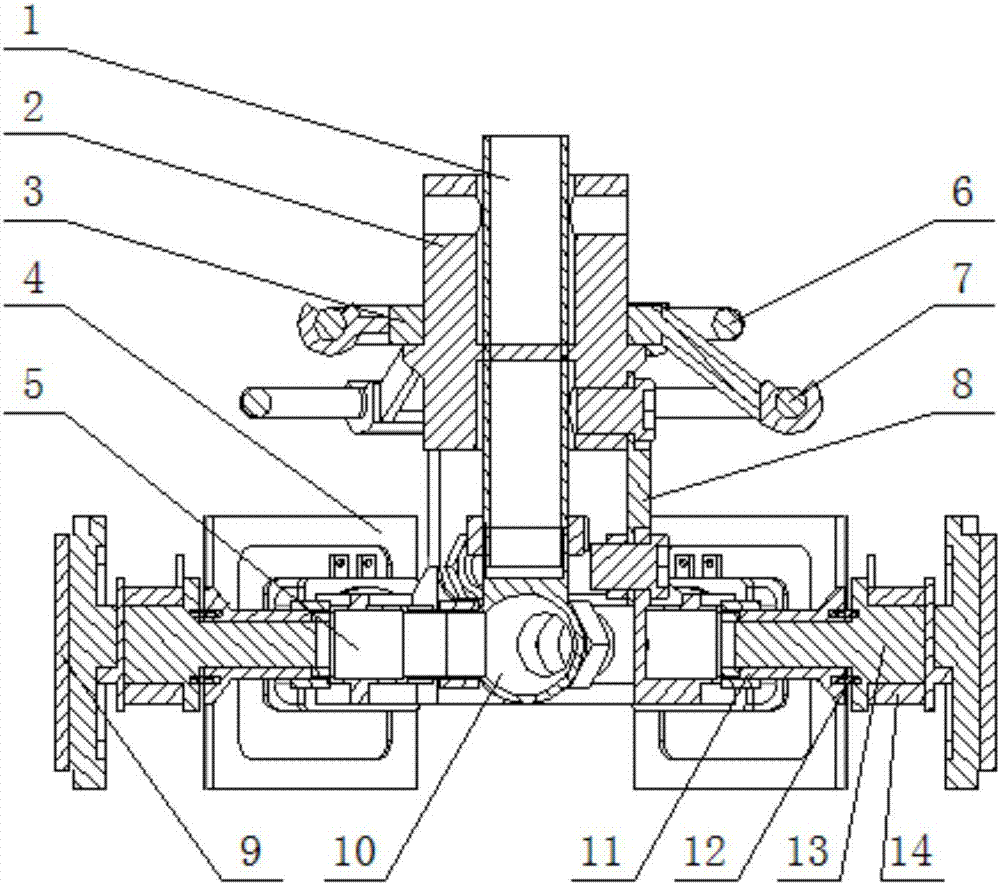

[0029] figure 1 Shown is the cross-sectional view of the permanent magnet mounting device of the outer rotor brushless DC motor. The permanent magnet mounting device of the outer rotor brushless DC motor is composed of three parts: the air guide ring assembly, the bracket assembly and the pneumatic arm assembly.

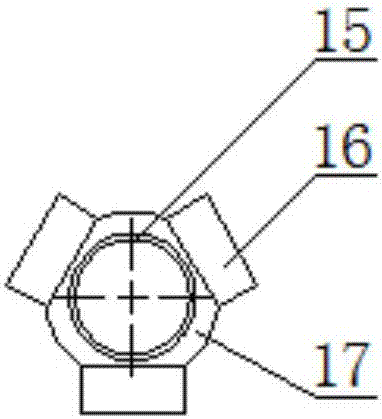

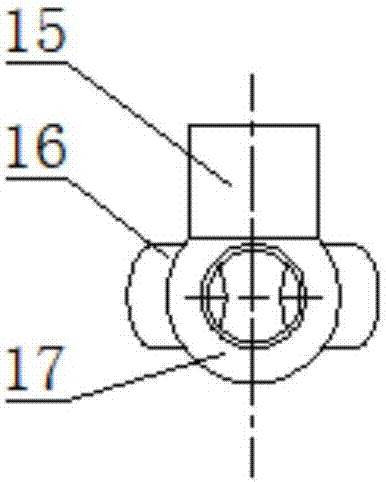

[0030] Among them, the air guide ring assembly is mainly composed of a leading air tube 1, a guiding ball 10, and an air guiding ring 5. The leading air tube 1 is connected to the leading air hole 15 of the guiding ball 10 through a nut, and the inner air guiding hole 21 of the air guiding ring 5 is connected to the main air hole 15 through a nut. The branch air guiding holes 16 of the guiding ball 10 are connected to each other.

[0031] Among them, the bracket assembly is mainly composed of the cantilever fixing column 2, the gas guide ring cantilever 8, the conductive ring fixing frame 3, the positive conductive ring 6 and the negative conductive ring 7, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com