Automatic missile hanging vehicle alignment method and system

A technology of a trailer and a motion control system is applied in the field of trailers and bullets, which can solve the problems of increasing labor costs, failure to mount bullets, and high risk factors, and achieve the effect of saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

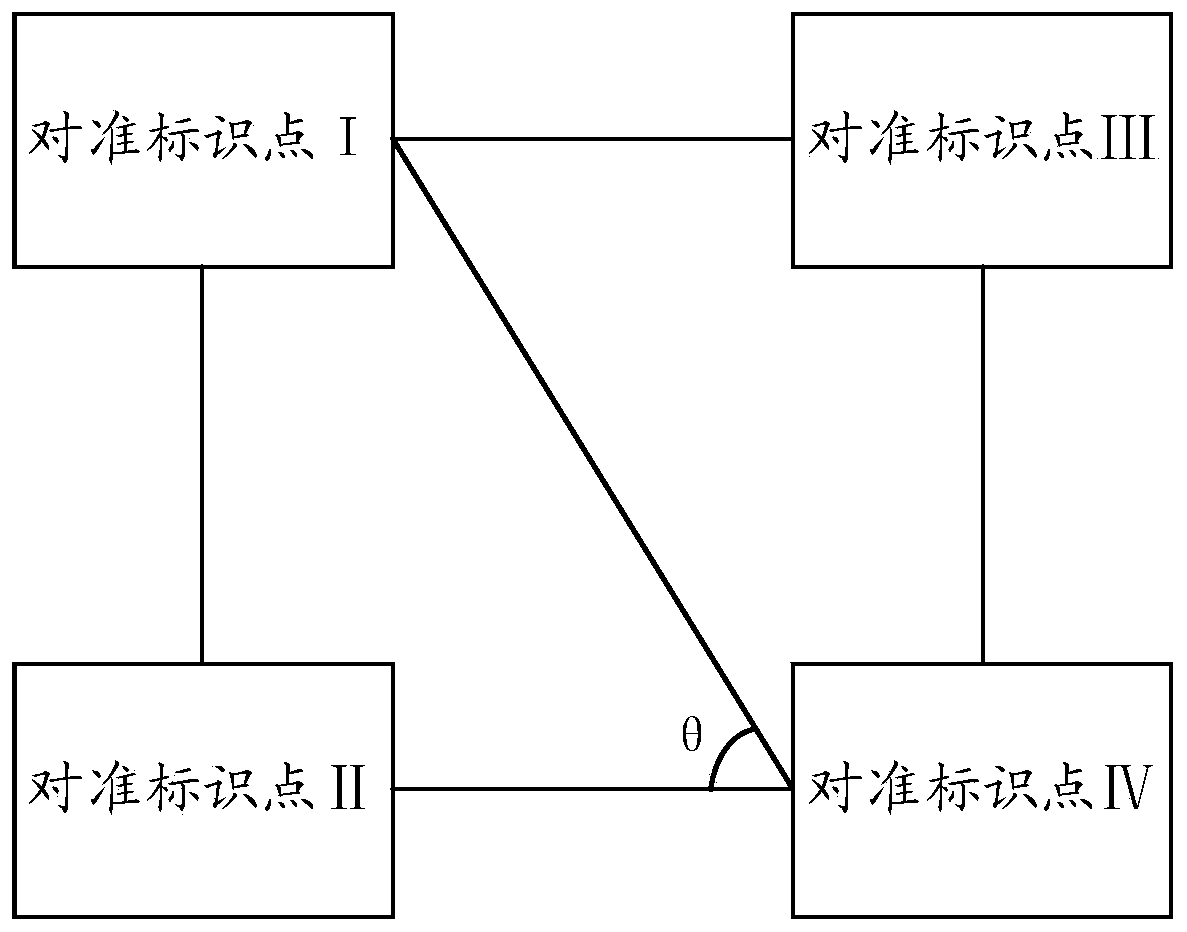

[0037] The invention discloses an automatic bomb vehicle alignment method and system, which can identify the alignment mark points on the hanger or the carrier through the vehicle-mounted visual sensor, obtain real-time position information, and automatically control the multi-degree-of-freedom motor, which can Carry out movements such as lifting, lowering, vertical movement, lateral movement, slewing, pitching, and rolling with the projectile, and send various projectiles to the suspension device, accurately position and complete the suspension.

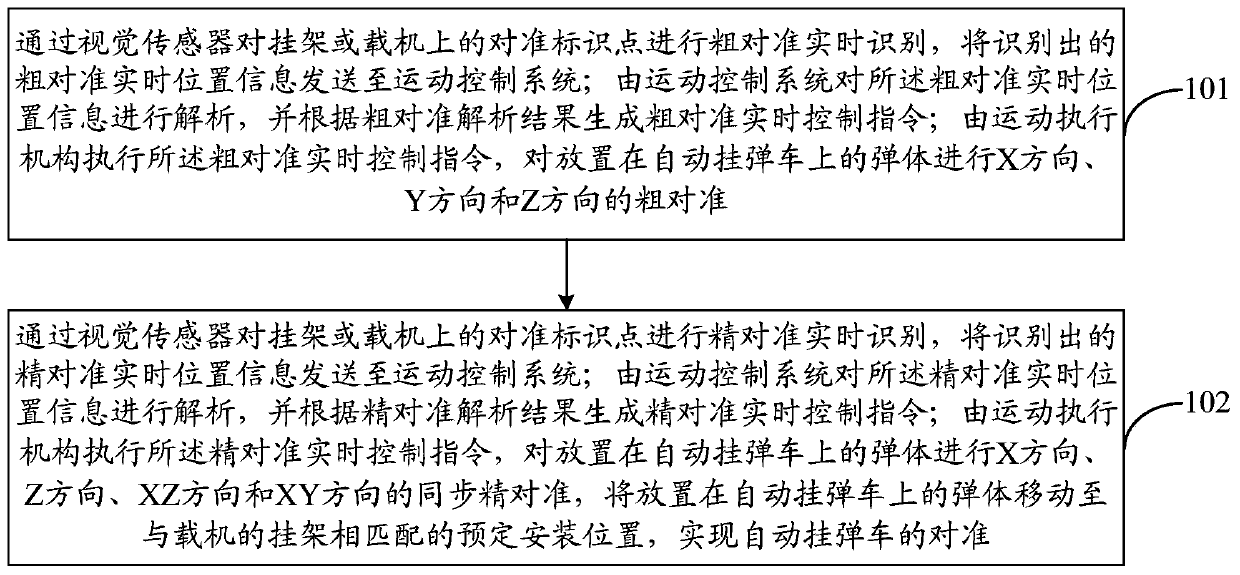

[0038] Such as figure 1 , in this embodiment, the automatic bomb vehicle alignment method may specifically include: sequentially performing rough alignment and fine alignment.

[0039] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com