Camera module test fixture

A camera module and testing tooling technology, which is applied in the direction of image communication, television, electrical components, etc., can solve the problems of consuming a lot of manpower and financial resources, increasing the cost of simulation, and increasing the workload of testers, so as to reduce workload and cost, Effect of reducing simulation cost and simplifying operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

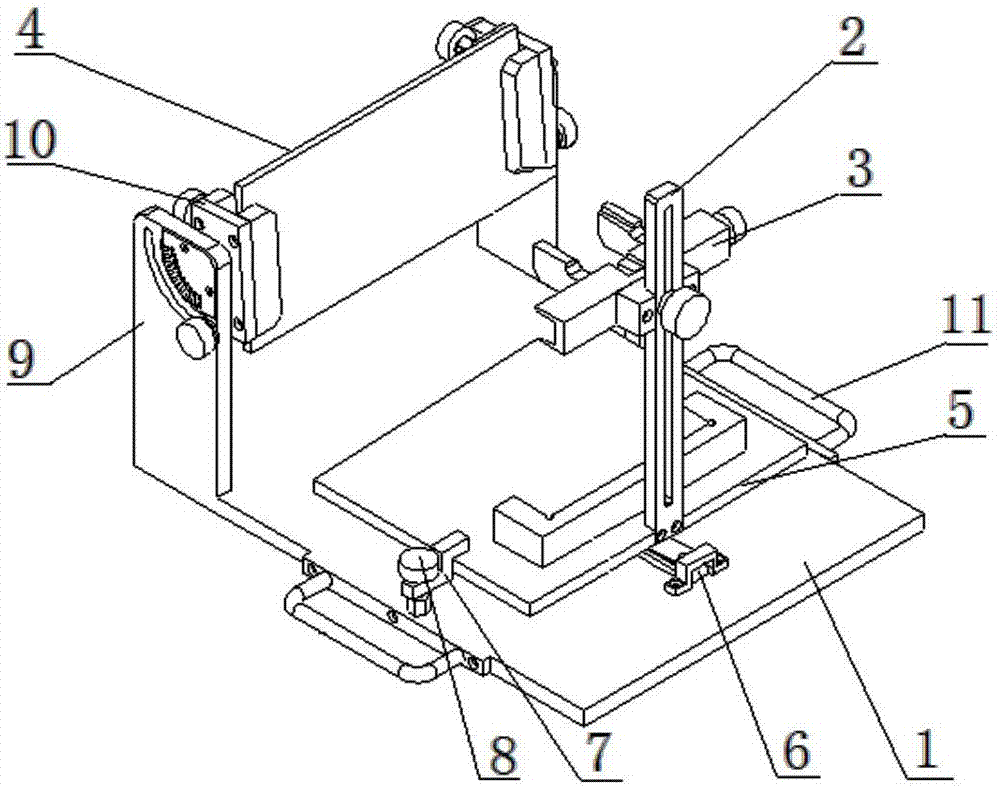

[0028] The core of this specific embodiment is to provide a camera module testing tool, which can reduce the workload and cost of camera module vehicle testing, and solve the current problems in this field.

[0029] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

[0030] The camera module testing tool provided in this specific embodiment mainly includes: a base 1 , a column 2 , a first fixture 3 , a second fixture, and a transparent plate 4 . Wherein, the column 2 is fixed to the base 1, and is arranged on the base 1 along the vertical direction; the first clamp 3 is used to fix the camera module, and the first clamp 3 is arranged on the column 2, and can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com