Multi-stage pulverizing device for electronic waste

A technology of electronic waste and pulverizing device, applied in the direction of grain processing, etc., can solve the problems of uneven pulverization, large manpower and time, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

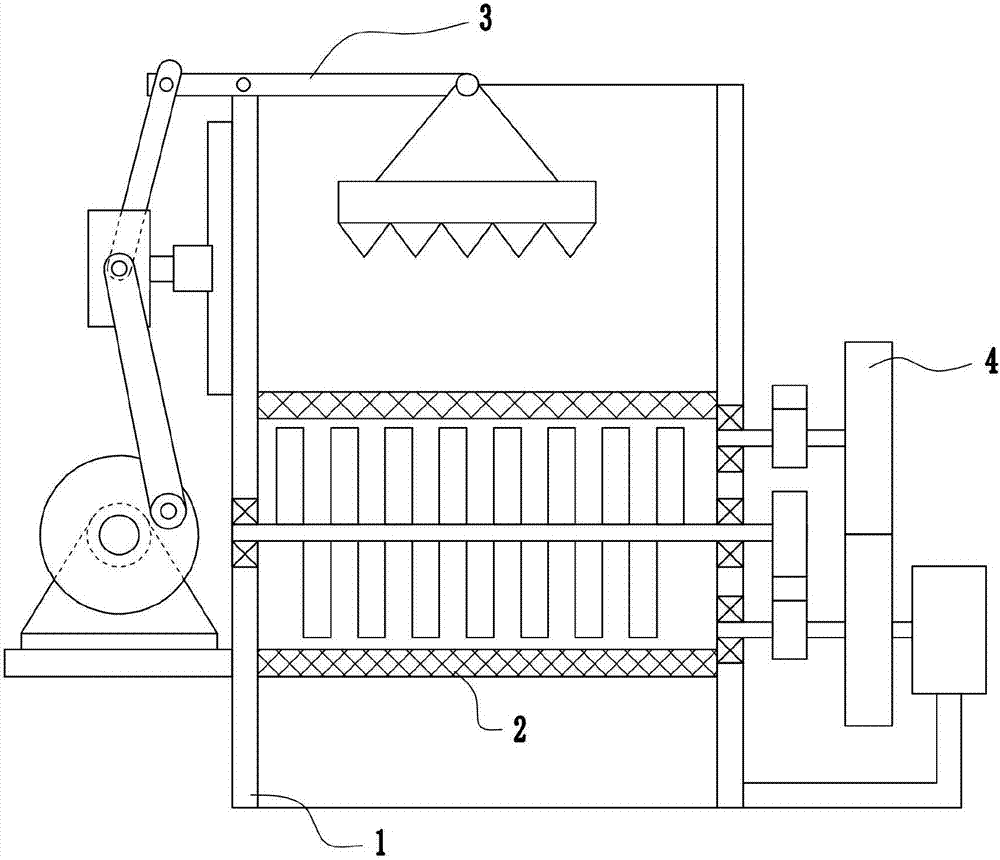

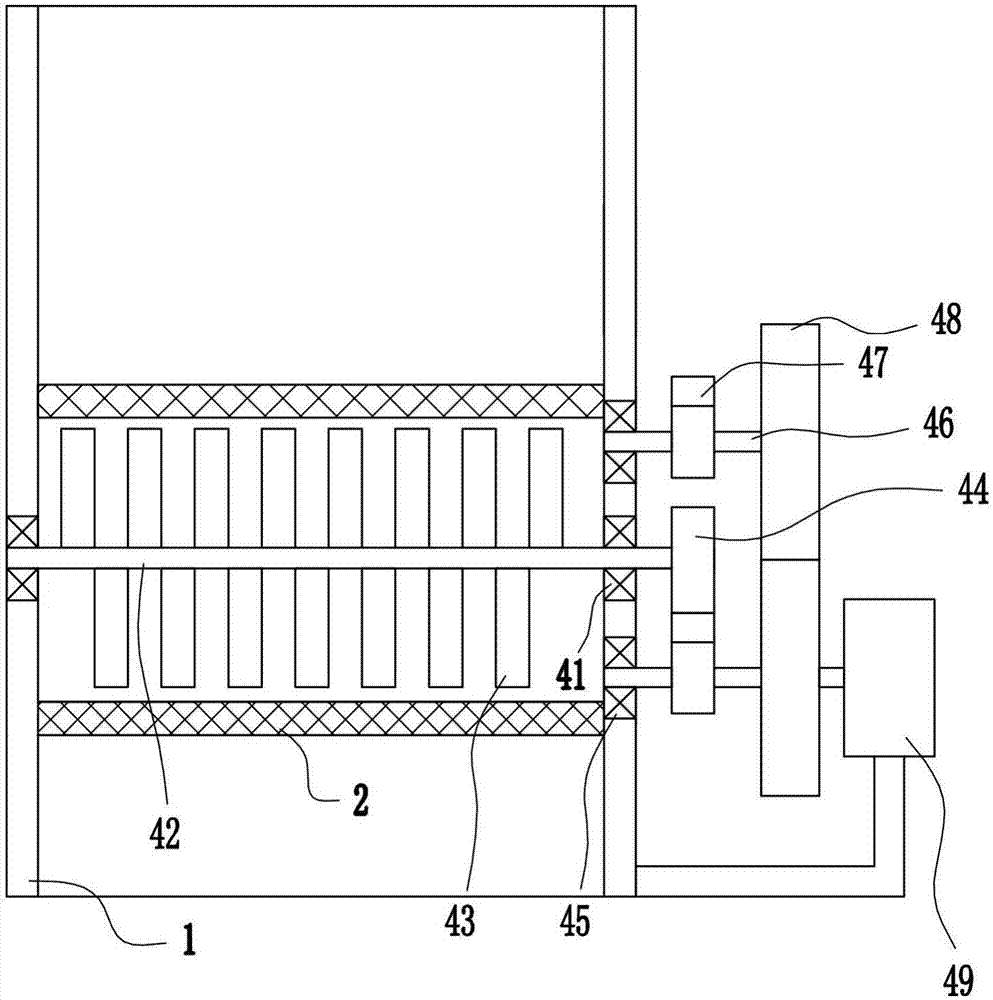

[0031] A multi-stage crushing device for electronic waste, such as Figure 1-5 As shown, it includes a crushing frame 1, a filter screen 2, a primary crushing mechanism 3 and a secondary crushing mechanism 4, the left side of the crushing frame 1 is connected with a primary crushing mechanism 3, and the right side of the crushing frame 1 is connected with a secondary crushing mechanism 4. The upper and lower sides of the crushing frame 1 are connected with filter screens 2, and the screen holes of the upper filter screen 2 are larger than those of the lower filter screen 2.

Embodiment 2

[0033] A multi-stage crushing device for electronic waste, such as Figure 1-5 As shown, it includes a crushing frame 1, a filter screen 2, a primary crushing mechanism 3 and a secondary crushing mechanism 4, the left side of the crushing frame 1 is connected with a primary crushing mechanism 3, and the right side of the crushing frame 1 is connected with a secondary crushing mechanism 4. The upper and lower sides of the crushing frame 1 are connected with filter screens 2, and the screen holes of the upper filter screen 2 are larger than those of the lower filter screen 2.

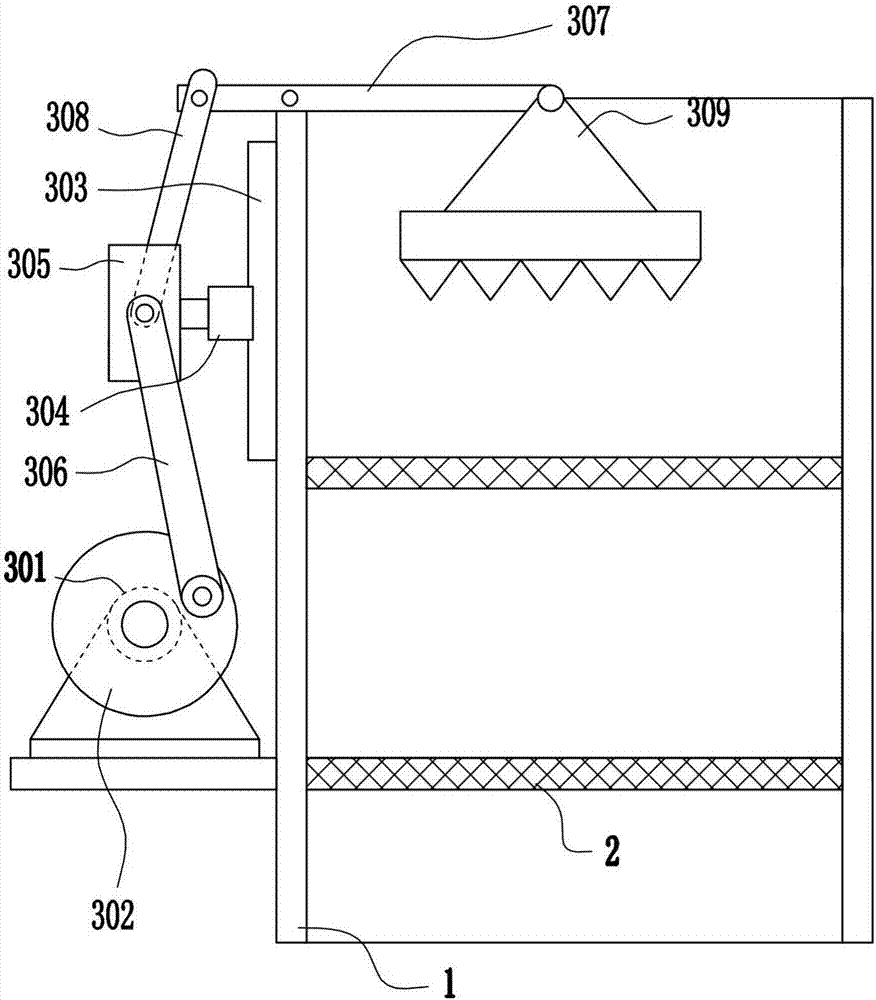

[0034] The primary crushing mechanism 3 includes a first motor 301, a rotating disk 302, a first slide rail 303, a first slider 304, a connecting plate 305, a first connecting rod 306, a first rotating rod 307, a second connecting rod 308 and a crushing mechanism. Teeth 309, the first motor 301 is installed on the lower side of the outer left wall of the crushing frame 1, the output shaft of the first mot...

Embodiment 3

[0036] A multi-stage crushing device for electronic waste, such as Figure 1-5 As shown, it includes a crushing frame 1, a filter screen 2, a primary crushing mechanism 3 and a secondary crushing mechanism 4, the left side of the crushing frame 1 is connected with a primary crushing mechanism 3, and the right side of the crushing frame 1 is connected with a secondary crushing mechanism 4. The upper and lower sides of the crushing frame 1 are connected with filter screens 2, and the screen holes of the upper filter screen 2 are larger than those of the lower filter screen 2.

[0037] The primary crushing mechanism 3 includes a first motor 301, a rotating disk 302, a first slide rail 303, a first slider 304, a connecting plate 305, a first connecting rod 306, a first rotating rod 307, a second connecting rod 308 and a crushing mechanism. Teeth 309, the first motor 301 is installed on the lower side of the outer left wall of the crushing frame 1, the output shaft of the first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com