injection molding machine

An injection molding machine, proportional technology, applied in the field of injection molding machines, can solve the problems of low precision of connecting rod and discontinuous temperature control of connecting rod, etc., and achieve the effect of improving precision and suppressing discontinuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

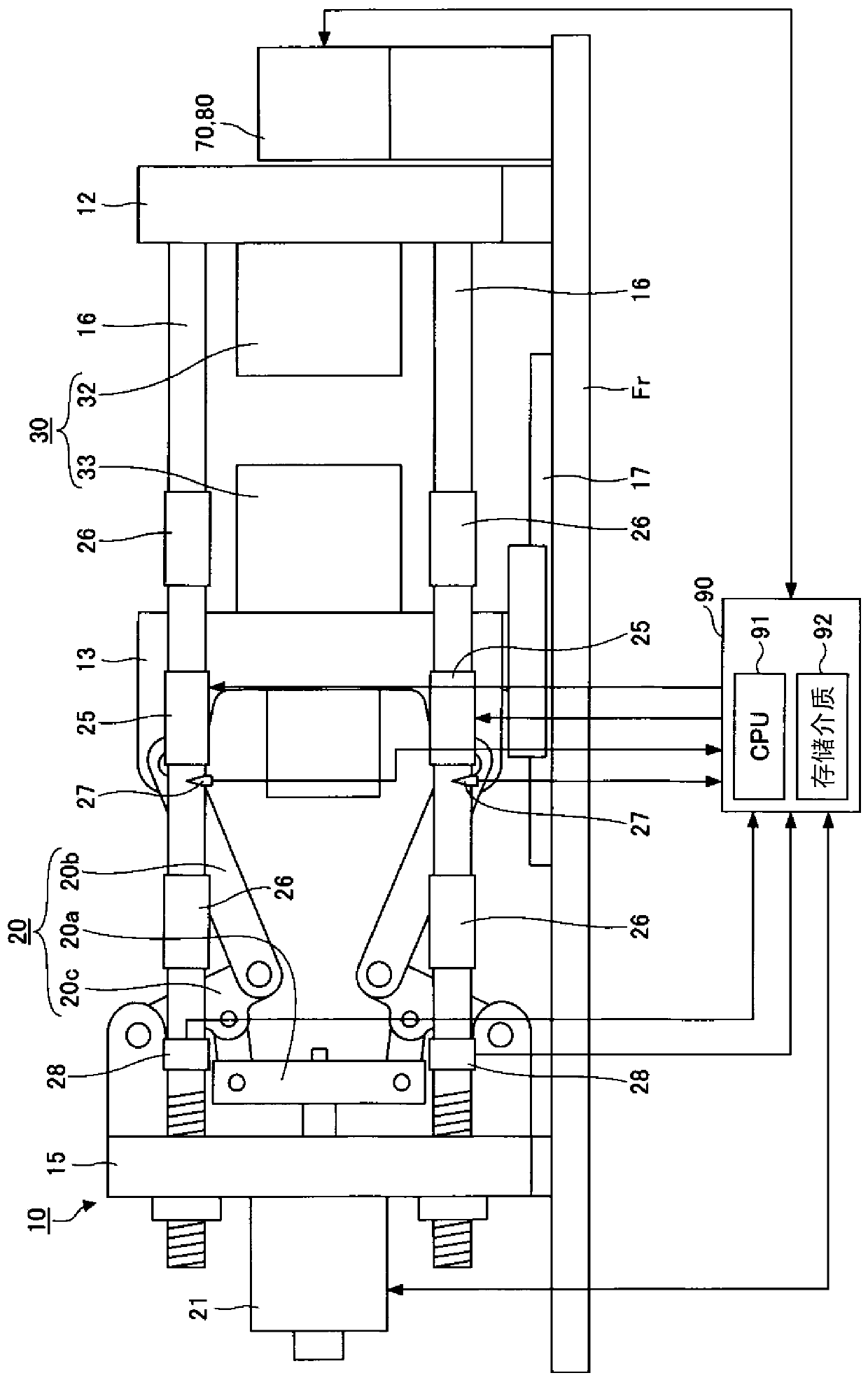

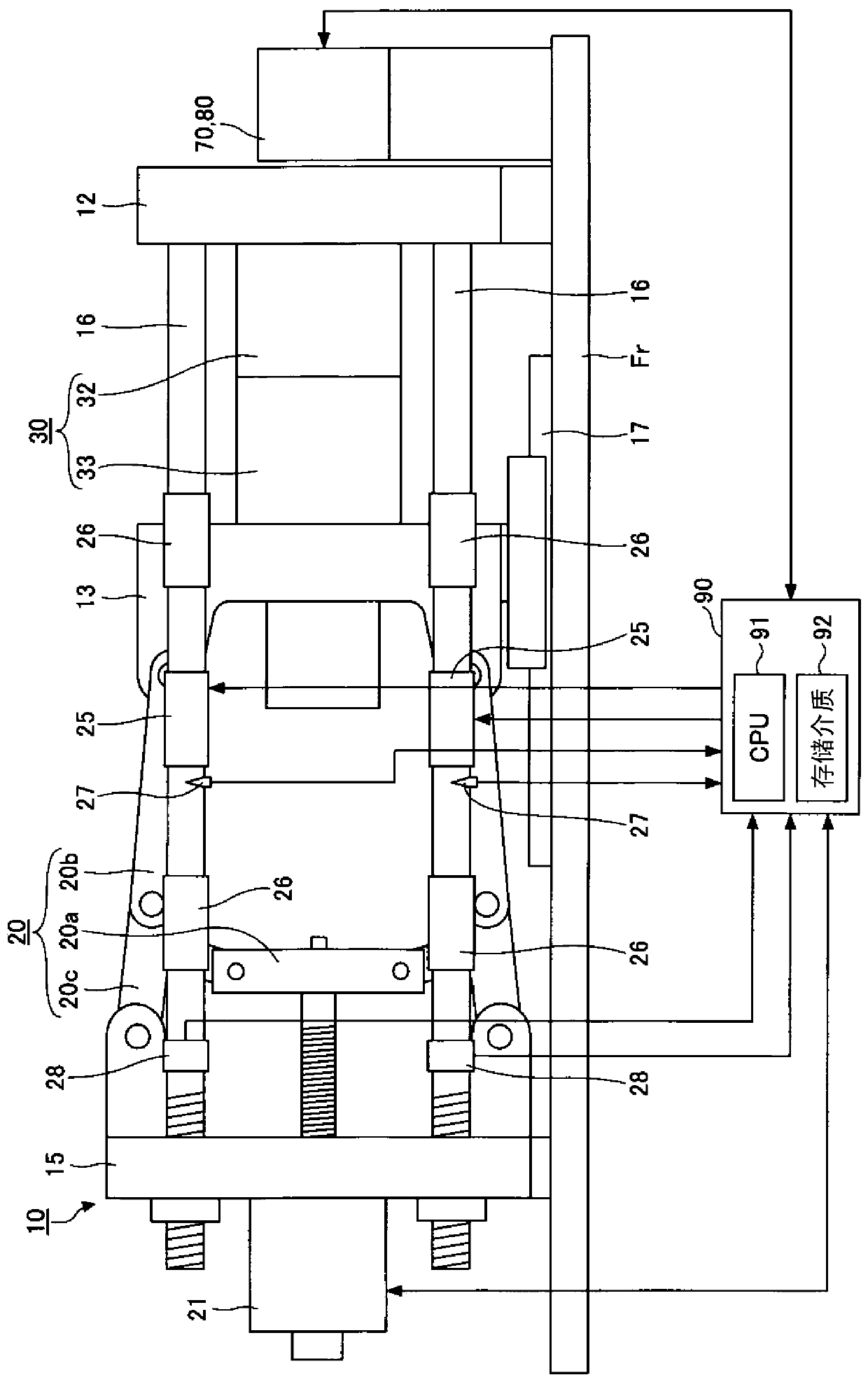

[0022] Hereinafter, the embodiments of the present invention will be described with reference to the drawings. In each of the drawings, the same or corresponding components are given the same or corresponding symbols and their descriptions are omitted.

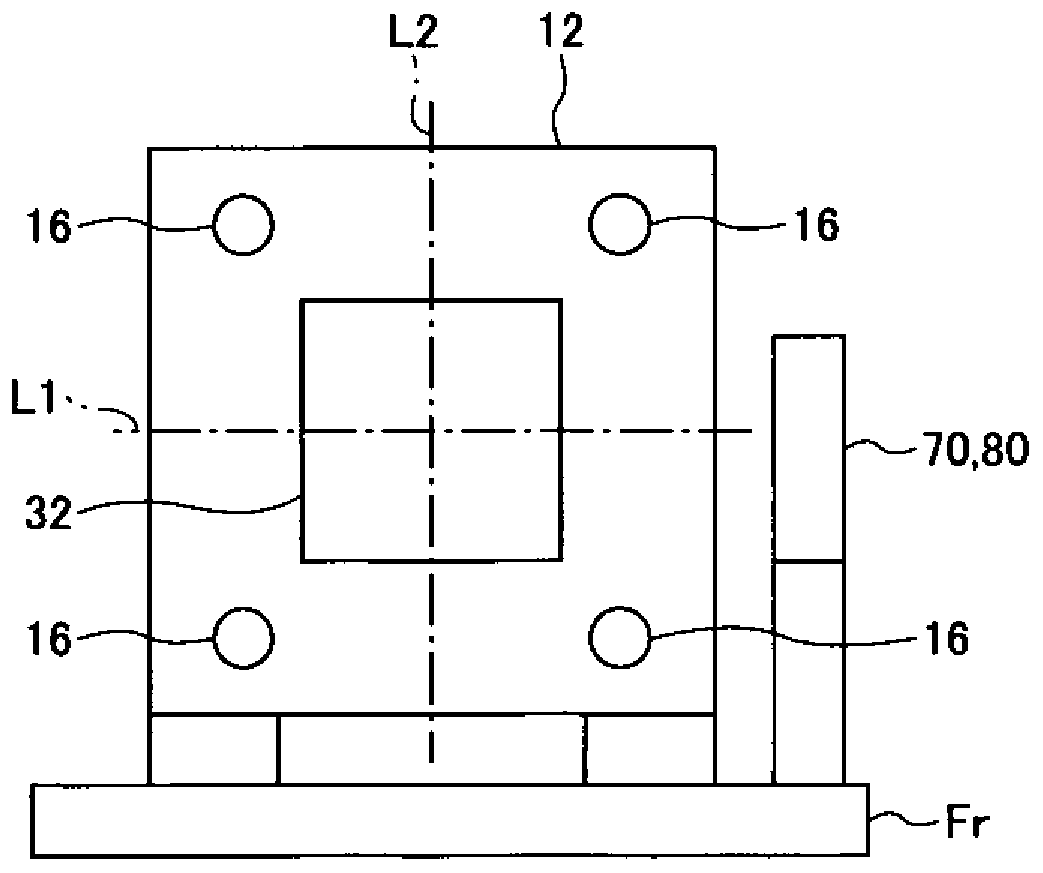

[0023] figure 1 It is a figure which shows the state at the time of completion of mold opening of an injection molding machine based on an embodiment. figure 2 It is a figure which shows the state at the time of mold clamping of the injection molding machine based on an embodiment. The injection molding machine has a frame Fr, a mold clamping device 10, an operating device 70, a display device 80, a controller 90, and the like.

[0024] The controller 90 has a CPU (Central Processing Unit) 91 and a storage medium 92 such as a memory. The controller 90 causes the CPU 91 to execute a program stored in the storage medium 92, thereby controlling the mold clamping device 10, the operating device 70, the display device 80, and the like....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com