Suction type laundry detergent bottle cap

A technology of laundry detergent and bottle caps, which is applied in the direction of capping with auxiliary devices, packaging, sealing parts with auxiliary devices, etc., which can solve the problems of excessive pouring, waste, and cumbersome quantitative process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

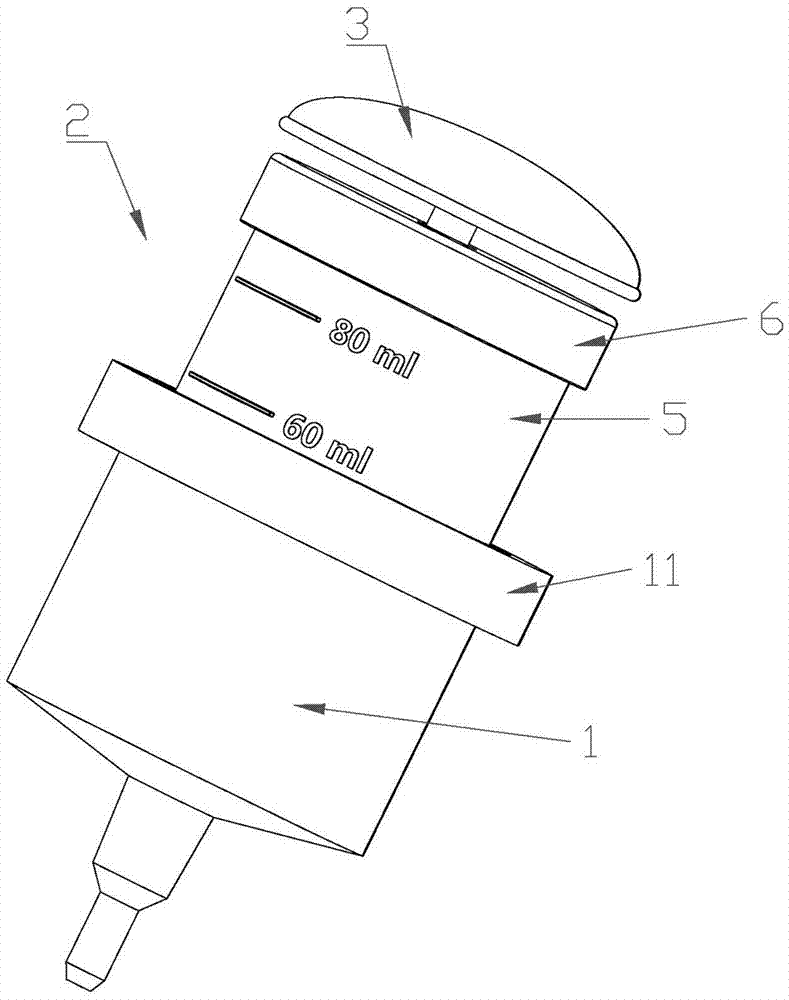

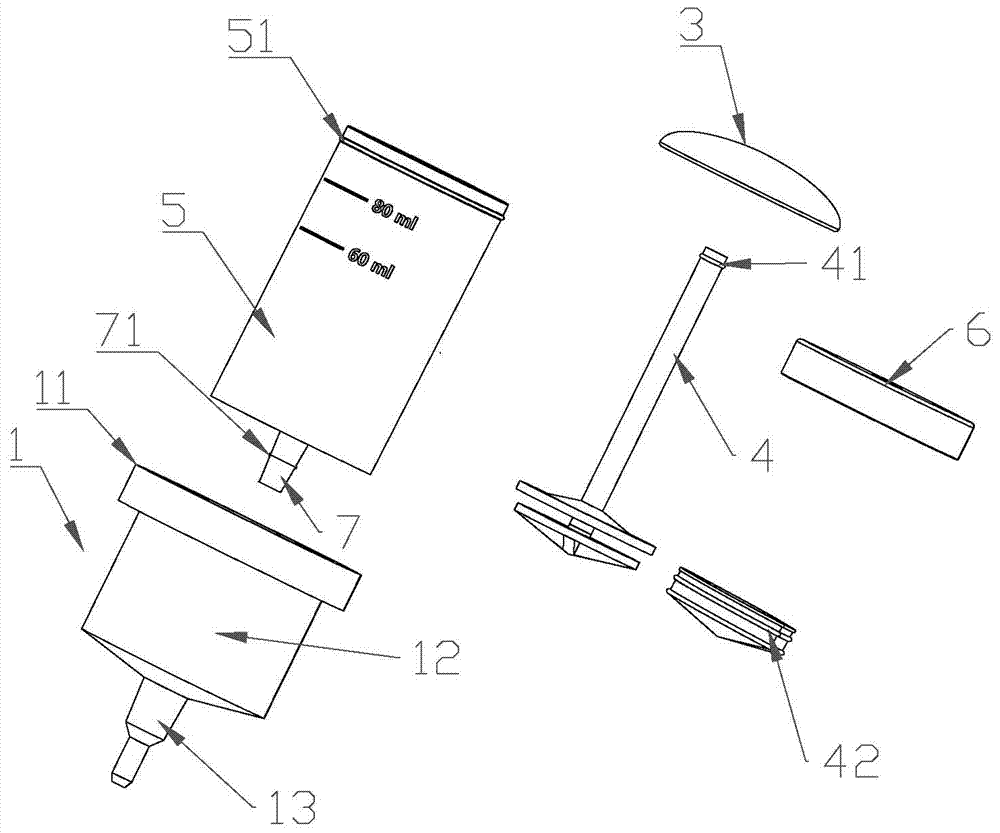

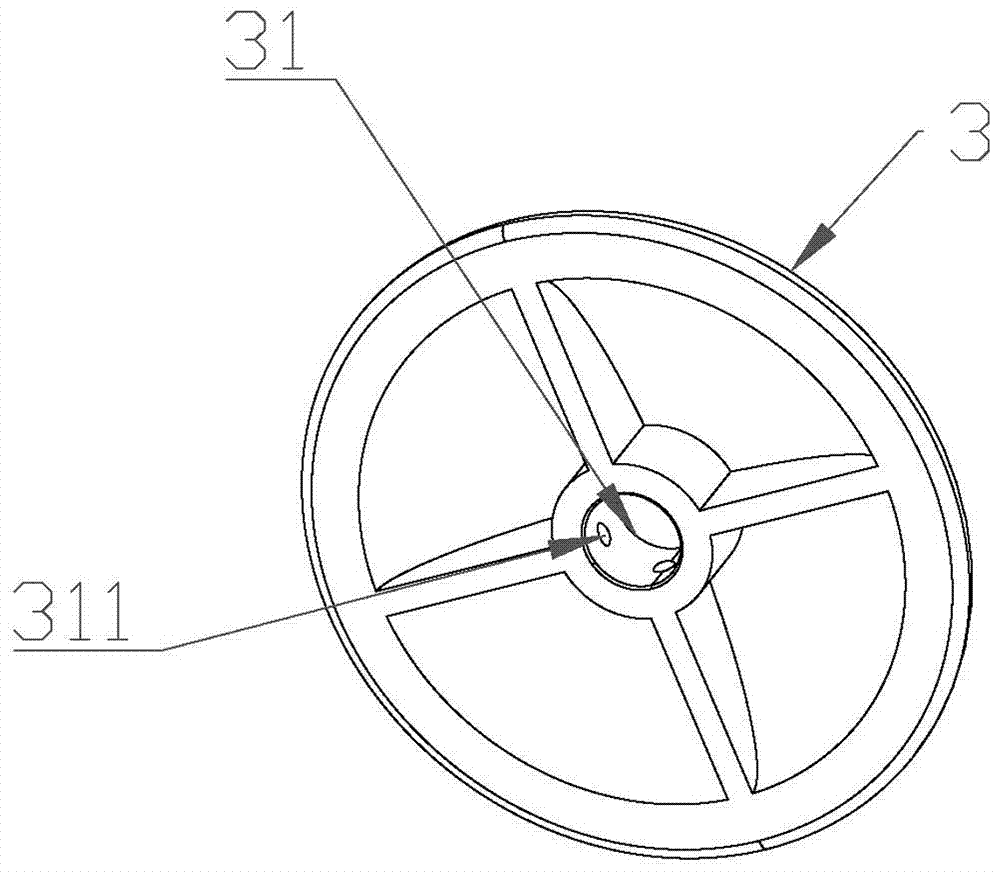

[0028] A kind of suction type laundry detergent bottle cap of the present embodiment, as Figure 1 to Figure 5 As shown, it includes a syringe structure 2 and a receiving cover 1 for connecting the bottle mouth of the bottle body. The bottom of the receiving cover 1 is provided with a pipeline connected to the inner bottom of the bottle body. The syringe structure 2 includes a top cover 6, a cylinder body 5, a push Pull rod 4, the push-pull cap 3 that is used to push-pull this push-pull rod 4 and the rubber cap 42 that is connected to the lower end of push-pull rod 4, top cover 6 covers the top of cylinder body 5 to form an airtight inner chamber, to prevent when extracting During the process, the push-pull rod accidentally slipped, the push-pull rod 4 was inserted into the cylinder body 5 and the rubber cap 42 was close to the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com