Taillight fixing device

A technology for fixing devices and tail lights, which is applied in the direction of fixing lighting devices, signal devices, lighting devices, etc., can solve the problems of poor fastening effect, inconvenient operation, limited space, etc., and achieve stable and firm fastening of lamps, convenient and effective operation. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

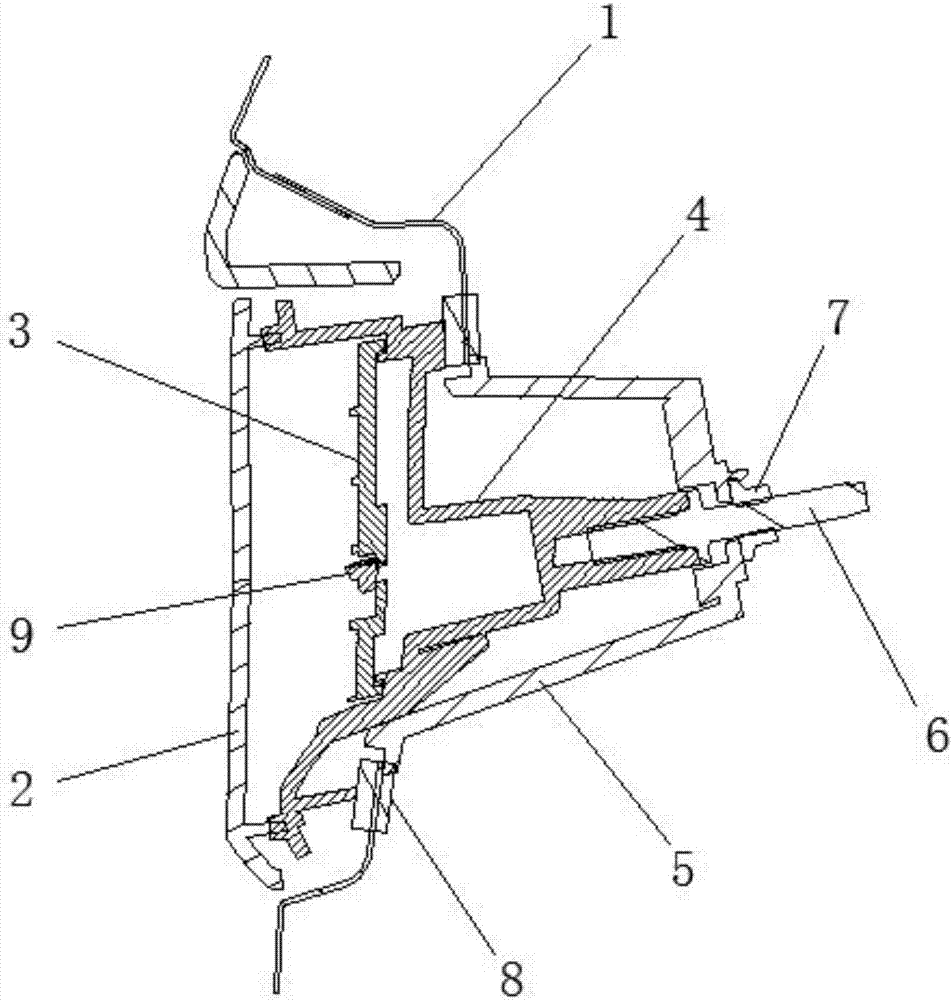

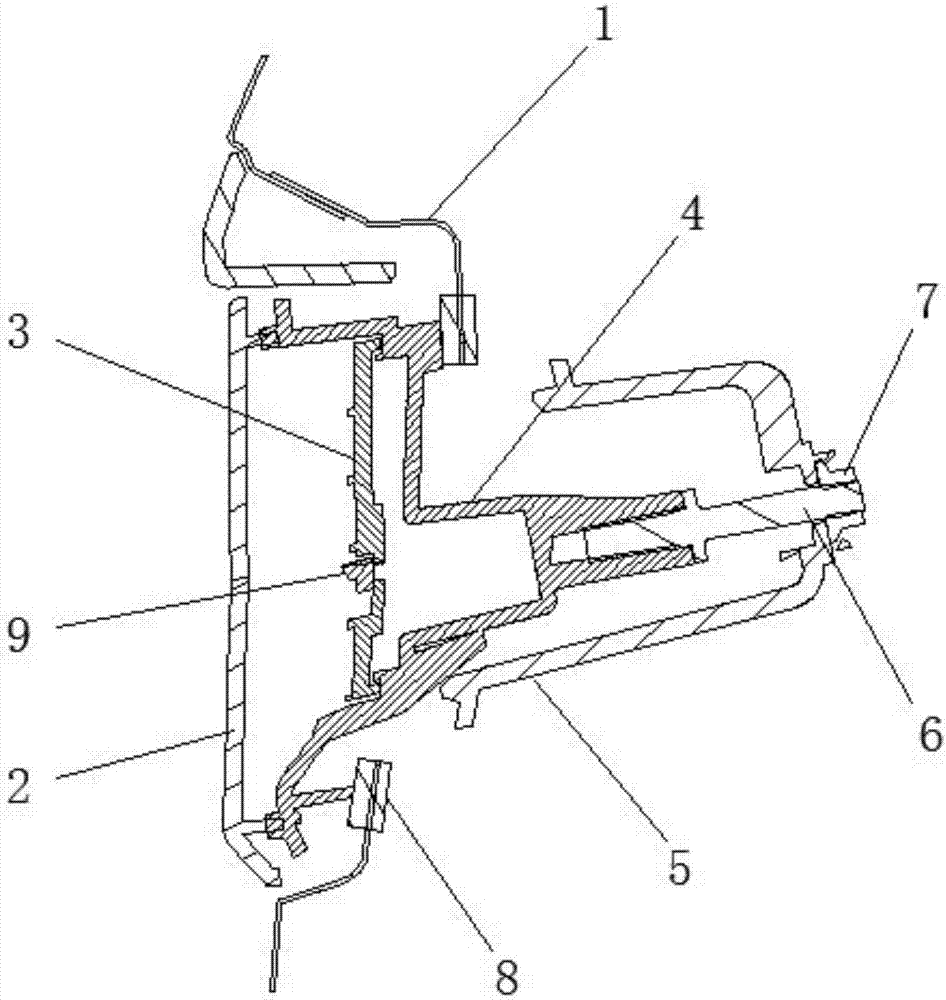

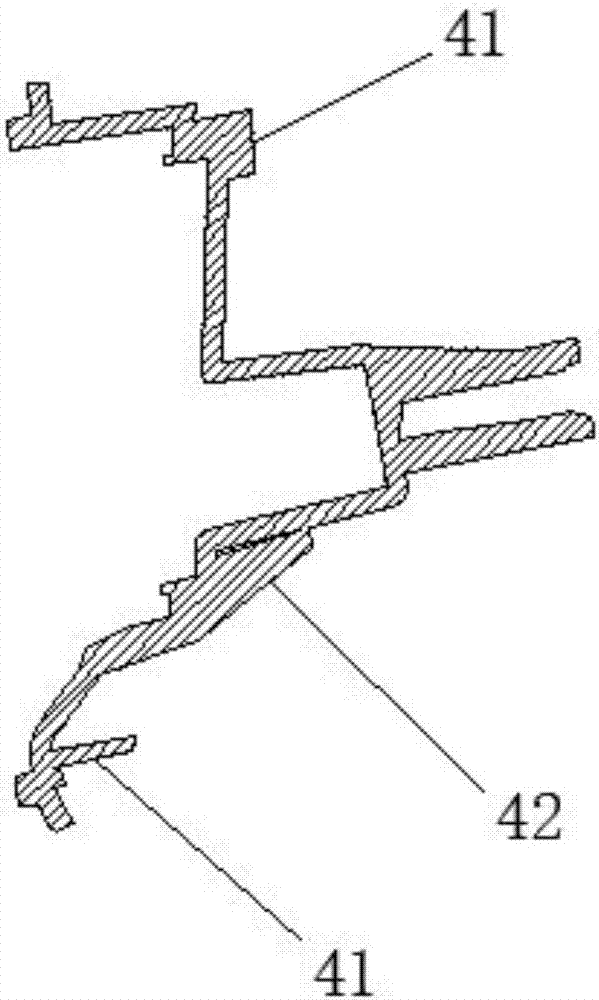

[0024] See Figure 1 to Figure 5 , the present invention has a lamp and a sheet metal 1; the lamp is fixedly arranged on the sheet metal 1; A light guide strip 9 is riveted; the lamp housing 2 is fixedly connected to the left end of the base 4; the secondary reflector 3 is fixedly arranged on the base 4 and is located between the lamp housing 2 and the base 4; A light guide strip 9 is hot riveted; the lamp housing 2 and the secondary reflector 3 are located on the left side of the sheet metal 1, and the fixing seat 5 is located on the right side of the sheet metal 1; the fixing bolt 6 is fixedly connected to the right end of the base 4; The fixed seat 5 includes an upper bracket 51, a lower bracket 52 and an intermediate body 53 connected together; the intermediate body 53 is provided with a guide hole 531 for the fixing bolt 6 to pass through; the free end of the upper bracket 51 and the lower bracket The free ends of 52 are all provided with briquetting block 54; The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com