A Deep Blue Light Organic Iridium(Ⅲ) Complex OLED Device

A complex and organic technology, applied in the field of OLED devices, can solve the problems of red shift of emission color and low quantum efficiency, and achieve the effects of low lighting voltage, high external quantum efficiency and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

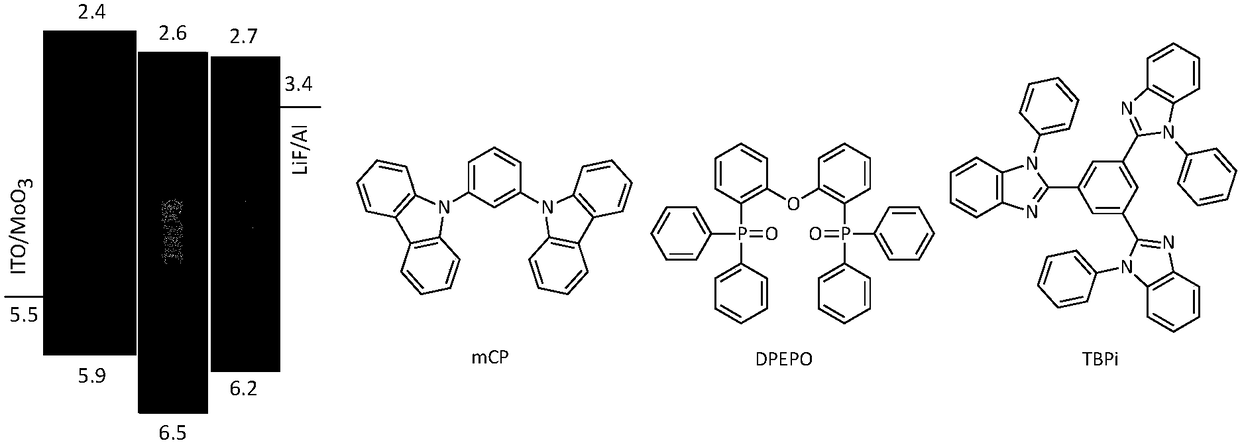

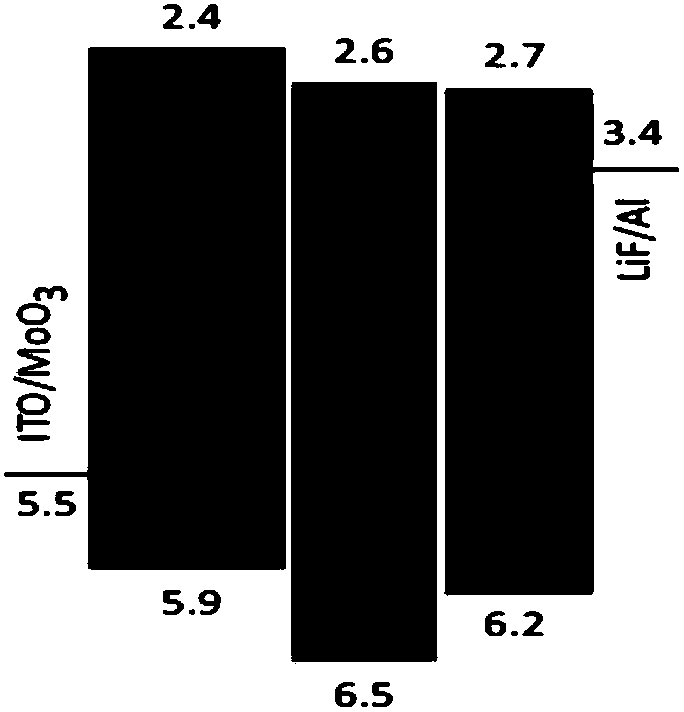

[0041] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0042] Manufacturing and testing of OLED devices: The device preparation in this part is completed in the composite evaporation system manufactured by Shenyang Huiyu Vacuum Technology Co., Ltd. In the organic chamber, the organic materials are placed in different evaporation sources whose temperature can be controlled separately. During the evaporation process, the vacuum degree of the chamber is higher than 9×10 -5 Pa, successively vapor-deposit hole injection layer, hole transport layer, light emitting layer, hole blocking layer, electron transport layer on anodized indium tin oxide (ITO) glass, and finally transfer the substrate to the metal evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com