Automatic wall slotting device

An automatic, wall technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of waste of labor, physical injury, dust and other problems, to reduce manual labor and improve cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is realized through the following technical solutions:

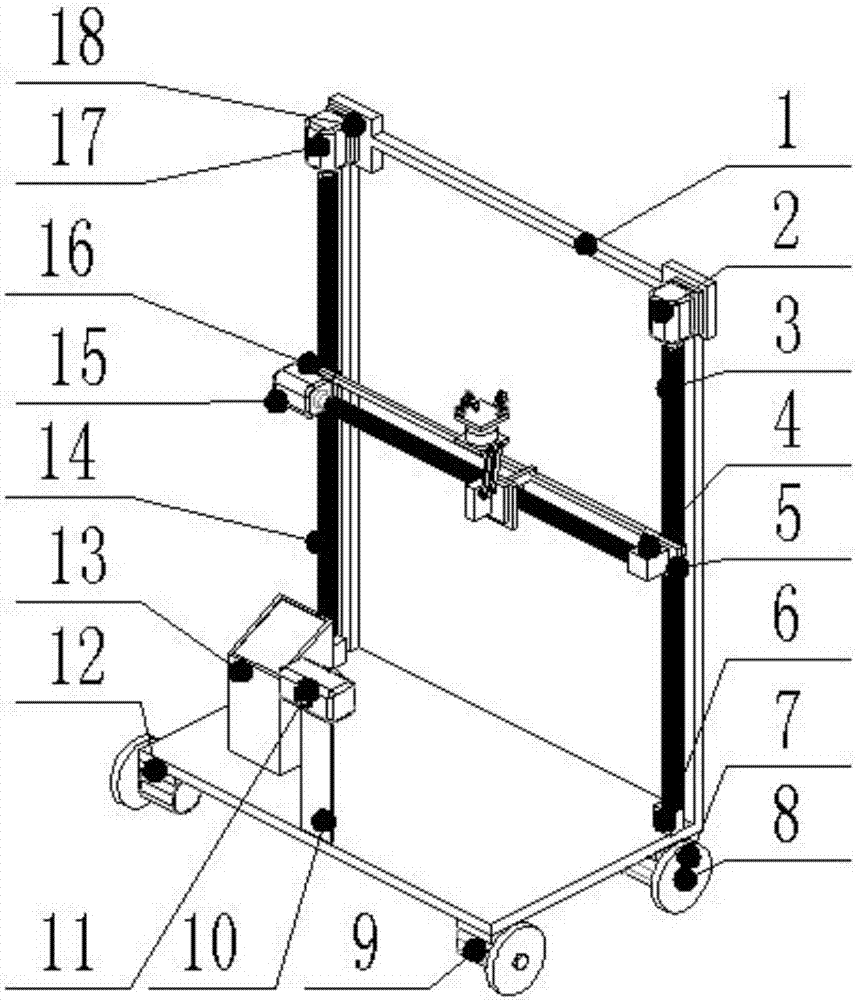

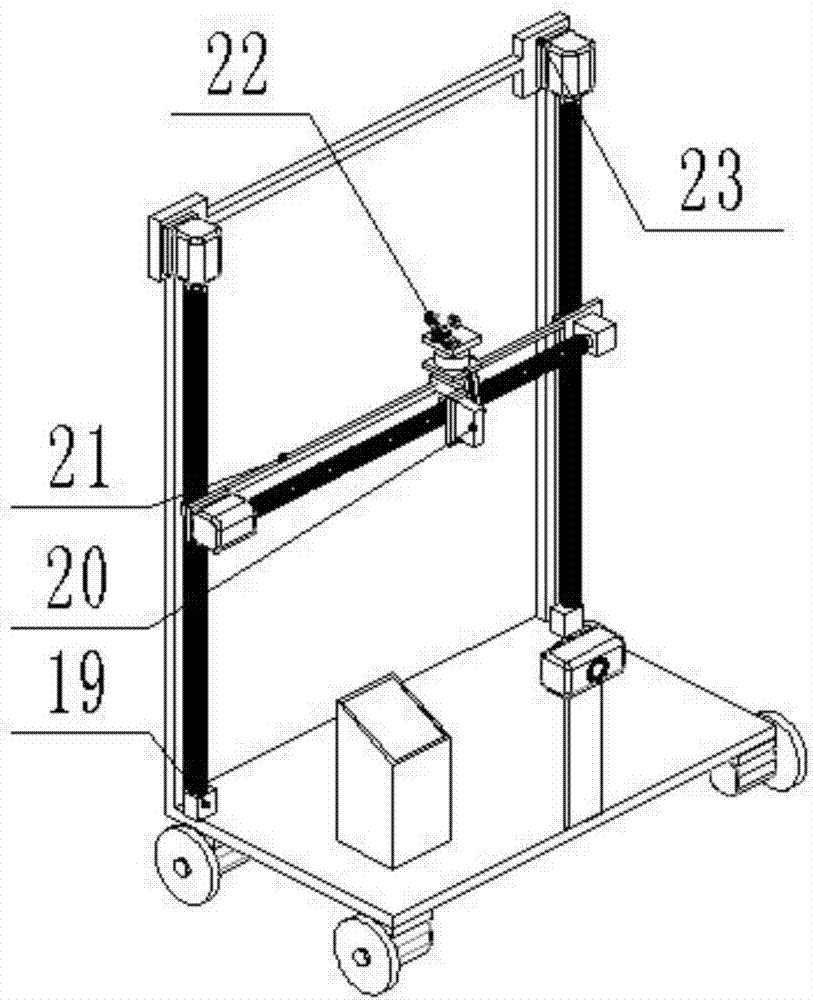

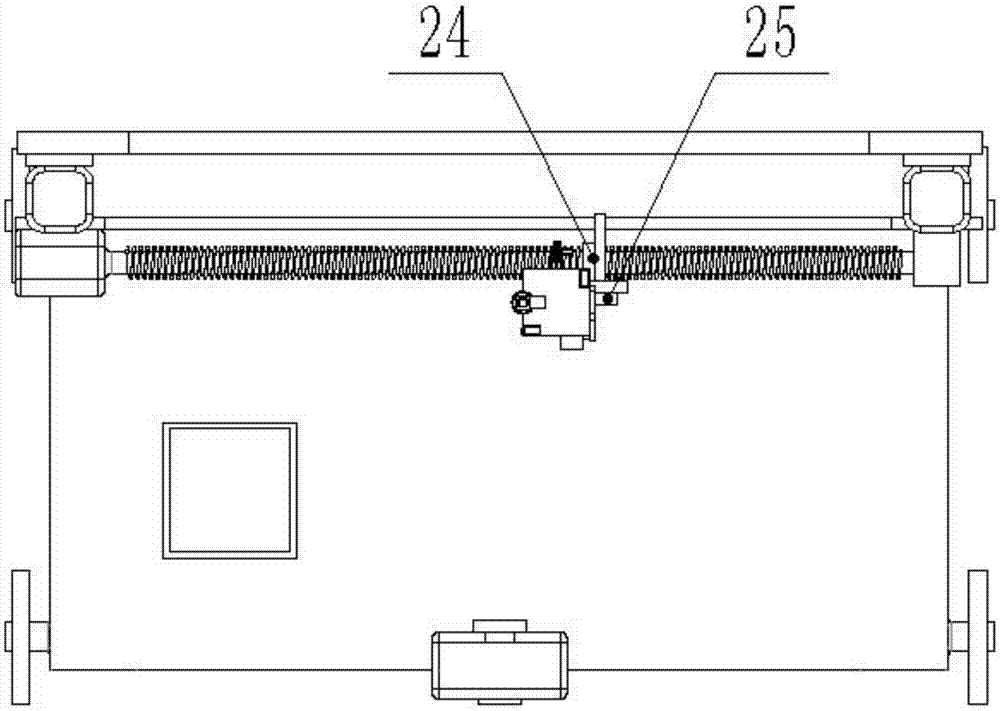

[0020] An automatic wall slotting device, comprising a first bracket 1, a first motor 2, a first screw 3, a second screw base 4, a first screw nut 5, a first screw base 6, and wheels 7 , wheel spindle 8, second motor 9, camera base 10, camera 11, second motor base 12, controller 13, third lead screw 14, third motor 15, third lead screw nut 16, fourth motor 17. The fourth motor base 18, the third screw base 19, the steering gear 20, the feed rod 21, the cutting device 22, the first motor base 23, the second screw nut 24, the steering gear base 25, the first Two supports 26, the third support 27 and the second lead screw 28, the first support 1 is fixed with the second motor base 12, the first motor 2 is installed on the first motor base 23, the first motor base 23, the first A screw 3 is fixed on the first motor 2 and installed concentrically with the first motor 2, the second screw base 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com