Simple dismounting and mounting structure of watchband, and watch

A simple disassembly and assembly technology, applied to watch straps, bracelets, clothing, etc., can solve the problems of high operator height, no professional tools for the strap, easy damage to the strap, etc., and achieve the effect of simple and quick installation or removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

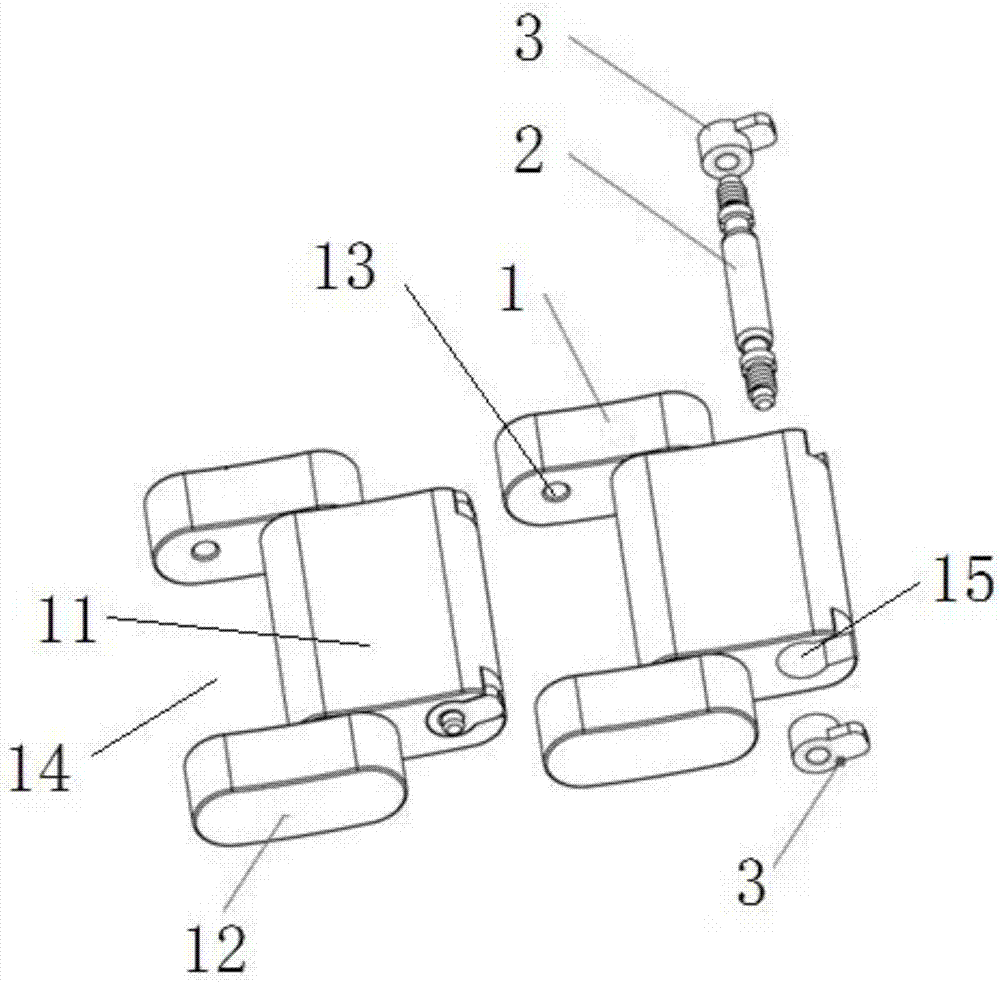

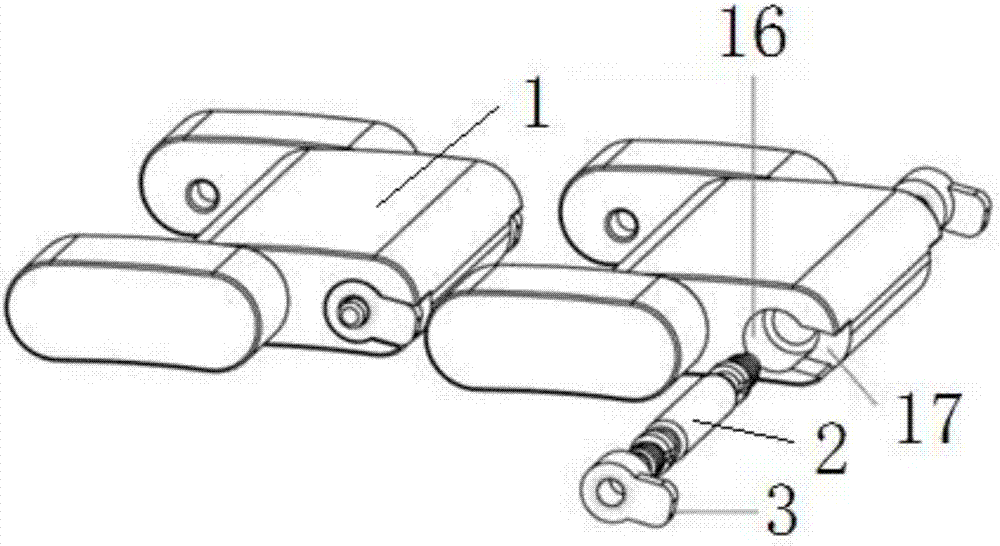

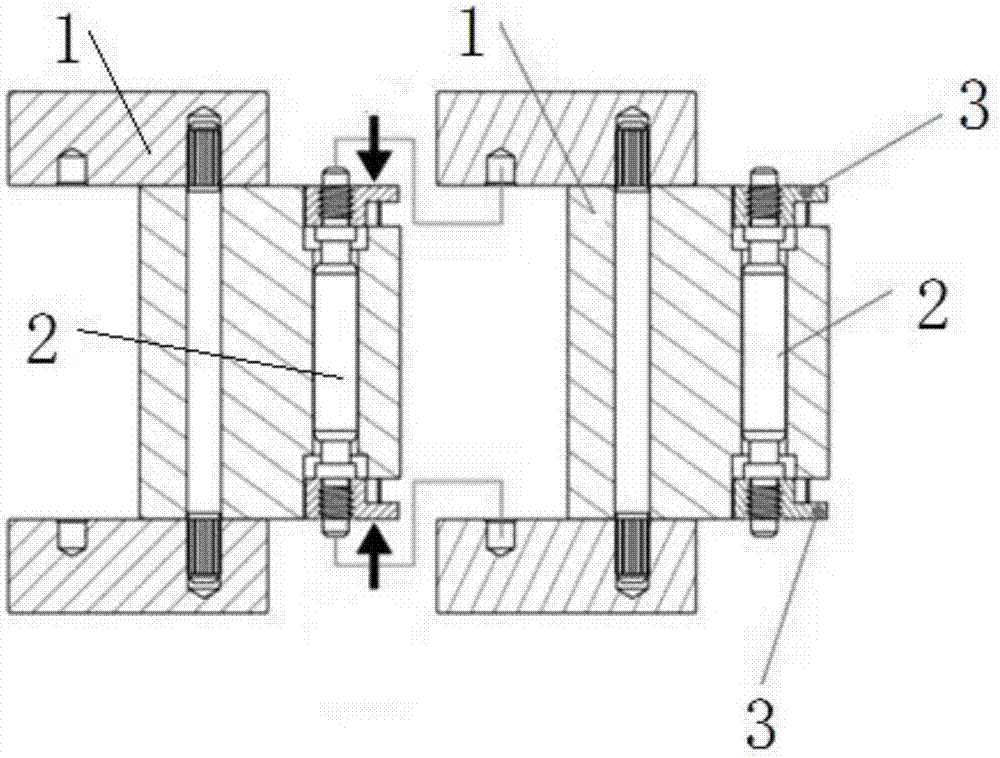

[0019] refer to Figure 1 to Figure 6 , a simple assembly and disassembly structure of a watch strap, comprising at least two strap beads 1 constituting the strap and a connection structure for connecting adjacent strap beads 1 between every two strap beads 1, a plurality of strap beads 1 are sequentially connected through a connecting structure to form a watch strap, and each bead 1 includes a head 11 and a tail 12 for connecting adjacent bead 1, wherein the tail 12 of bead 1 is provided with a socket for accommodating adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com