Frame carrying and storage rack

A frame and shelf technology, applied in the field of process equipment, can solve problems such as fracture damage, impact deformation of parts, etc., to achieve the effect of convenient use, solving mutual collision, and efficient process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

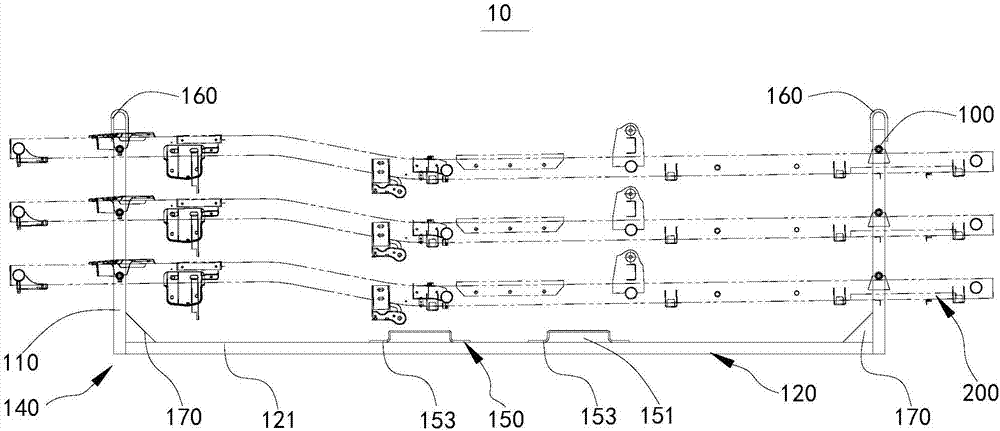

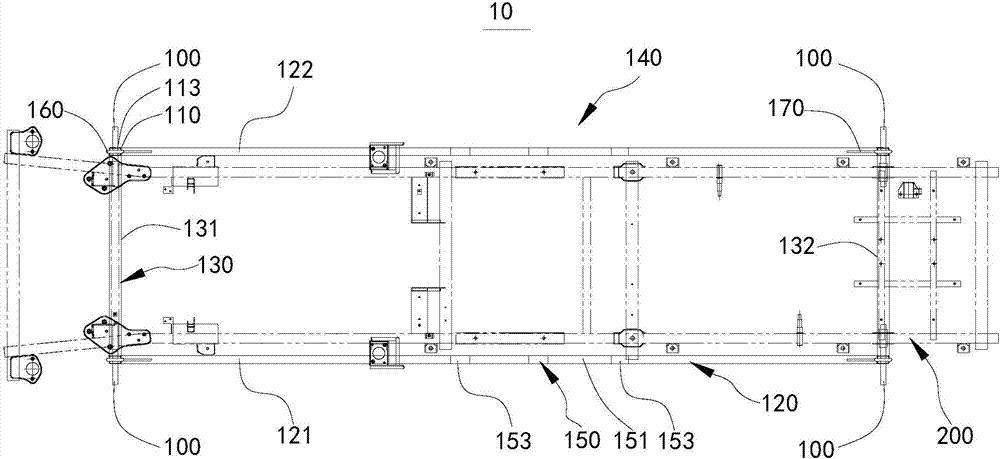

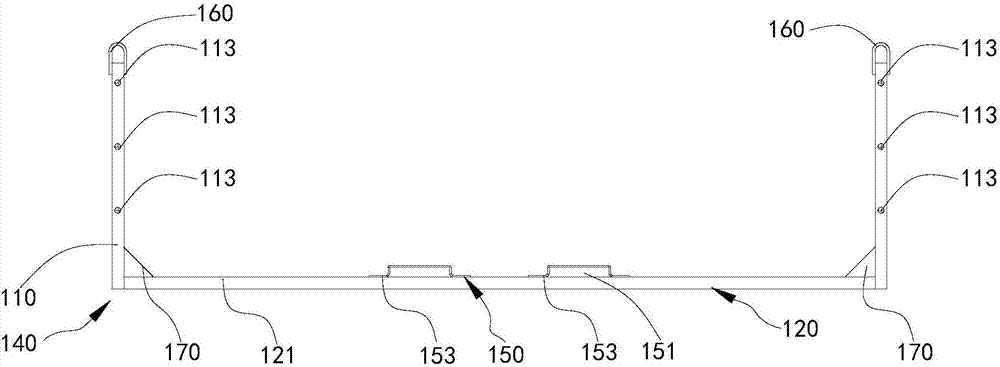

[0051] figure 1 A schematic structural diagram of a vehicle frame handling and storage rack 10 provided in this embodiment. figure 2 for figure 1 Schematic diagram of another view of the structure. combine figure 1 and figure 2 and can be compared with each other to see the characteristics of each component of the vehicle frame handling and storage shelf 10 and the connection relationship between each component. What needs to be explained here is that, if figure 1 and figure 2As shown in , in order to more clearly express the characteristics of the corresponding parts of the vehicle frame handling and storage rack 10, the storage object of the vehicle frame handling and storage rack 10—the vehicle frame 200 is represented by a double-dot dash line and treated as transparent.

[0052] Please refer to figure 1 ,From figure 1 As can be seen from the figure, a frame handling and storage rack 10 includes a plurality of supports 100 , a plurality of columns 110 , a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com