Automatic flattening device for material distributing machine

A distributing machine and automatic technology, applied in the direction of supplying devices, manufacturing tools, etc., can solve the problem of single distributing operation of the distributing machine, achieve the effects of reducing labor intensity and cost, avoiding obstacles, and improving progress and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

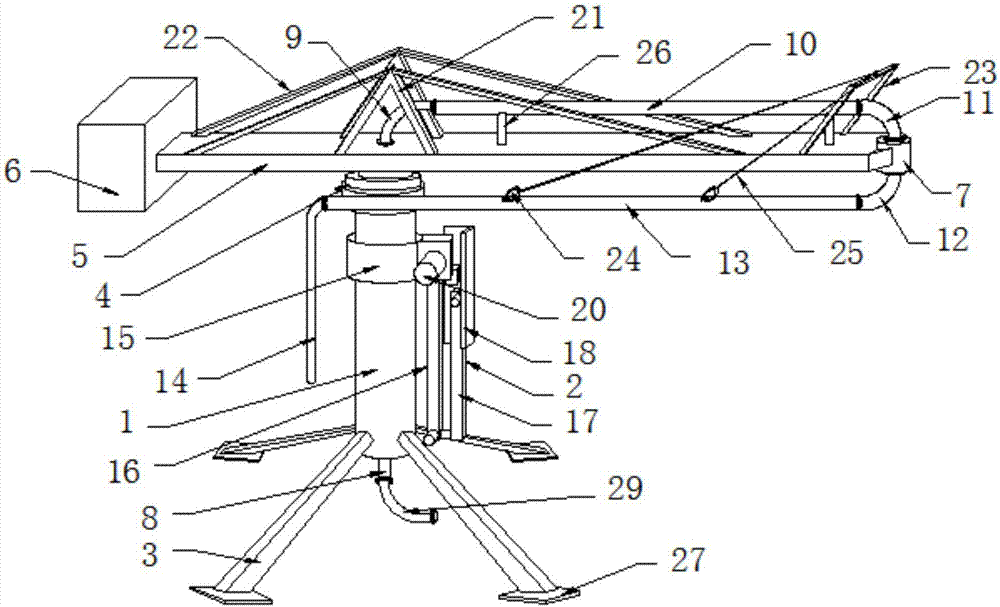

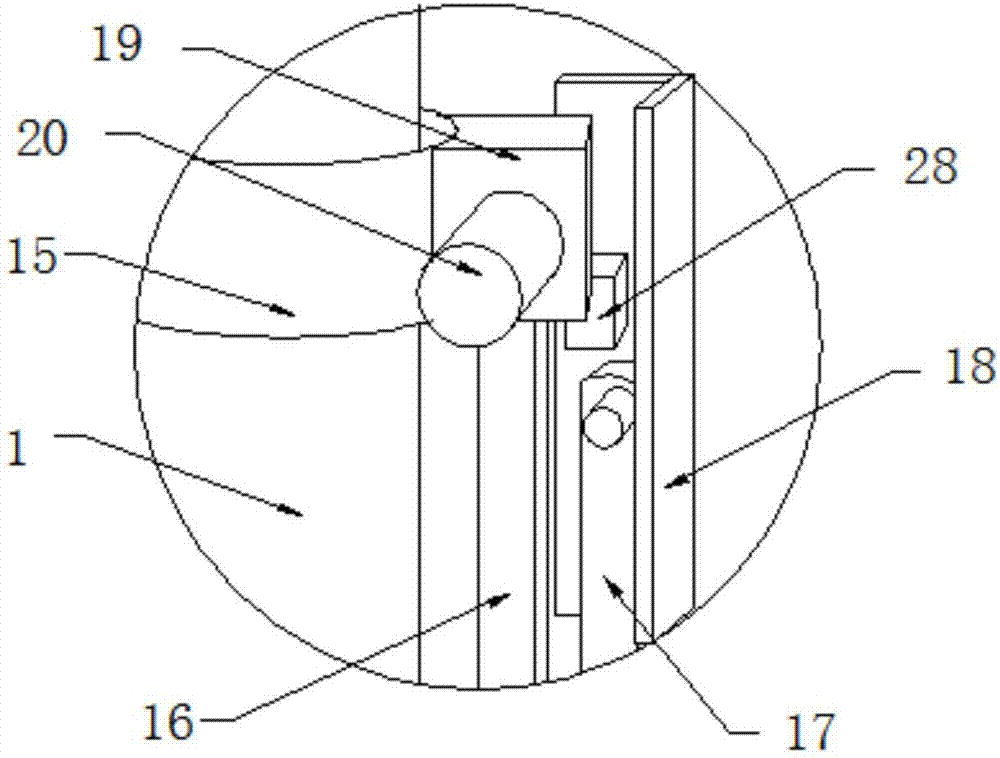

[0023] Such as Figure 1-3 As shown, the automatic leveling device of the cloth machine of the present invention includes a cloth support 1 and an automatic leveling device 2,

[0024] The bottom of the cloth support 1 is evenly provided with four legs 3, the top of the cloth support 1 is provided with a slewing support 4, the slewing support 4 is provided with a main beam supporting frame 5, and one end of the main beam supporting frame 5 is provided with The counterweight box 6, the other end of the main beam supporting frame 5 is provided with a small bearing 7, the inside of the fabric support 1 is provided with a vertical pipe 8, the top of the vertical pipe 8 is provided with a first elbow bearing 9, and the first elbow bearing 9 is provided on the top of the vertical pipe 8. The other end of a curved tube bearing 9 is provided with a horizontal tube 10, and the other end of the horizontal tube 10 is provided with a second curved tube bearing 11, and the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com