Novel mute dedusting and spraying device

A spray device and silent technology, applied in the field of spray cleaning devices, can solve the problems of flying dust, loud noise, etc., and achieve the effect of solving the problem of high noise and convenient disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

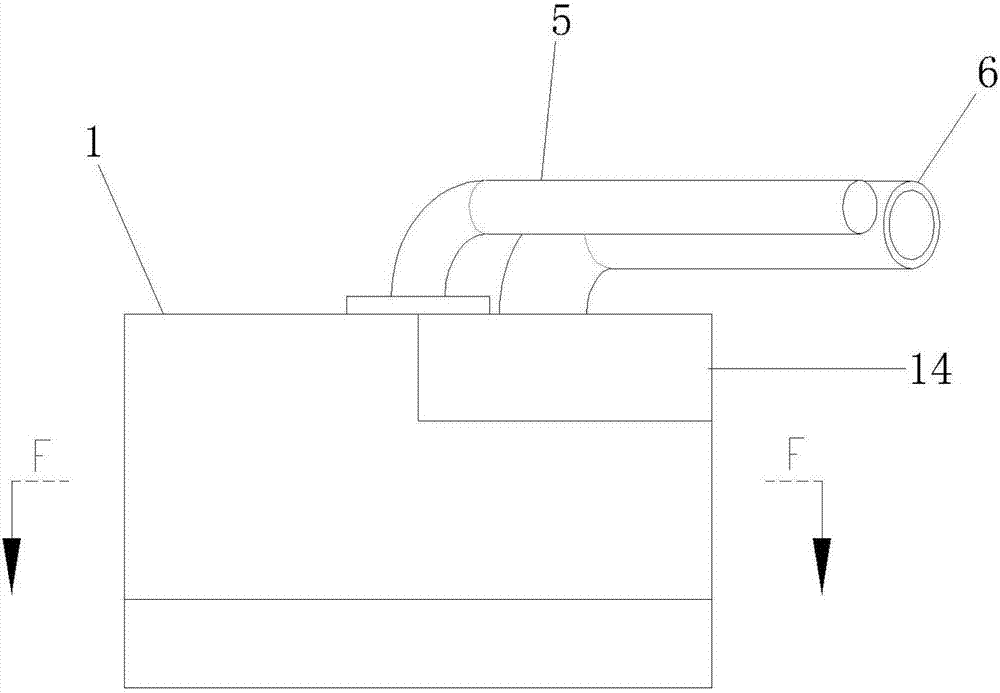

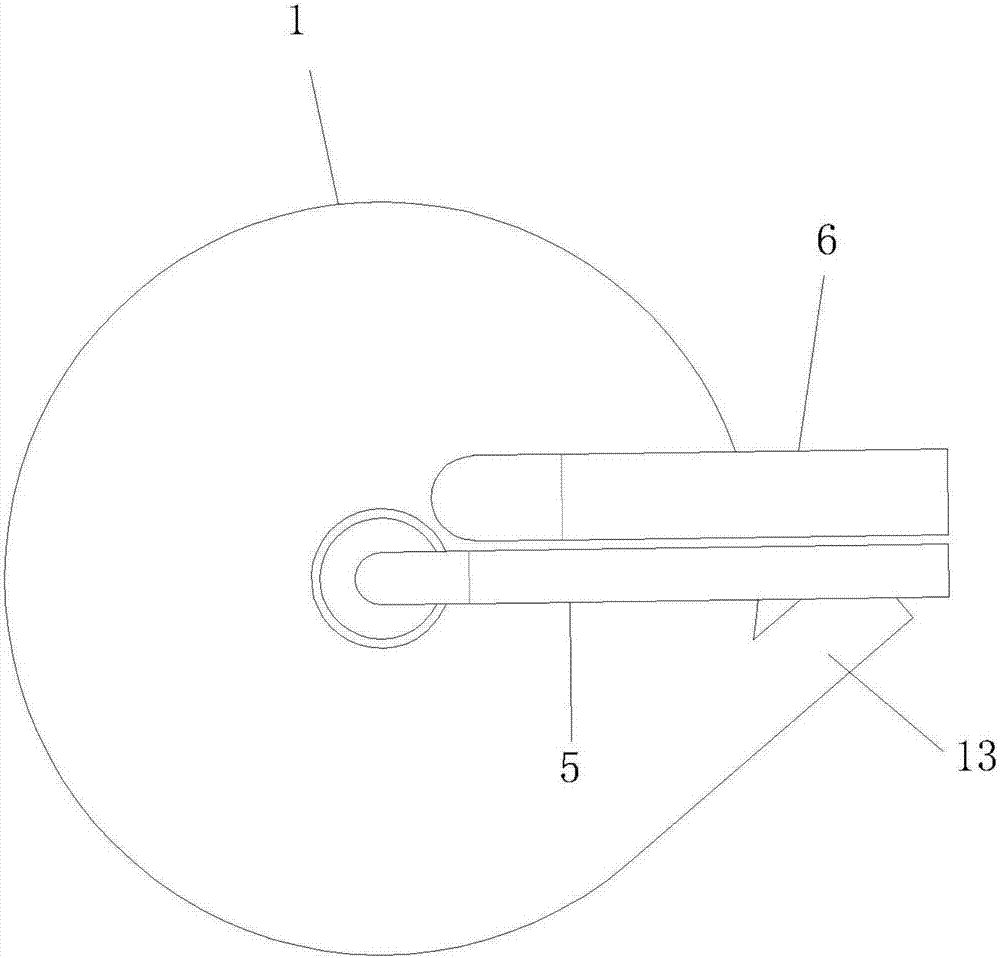

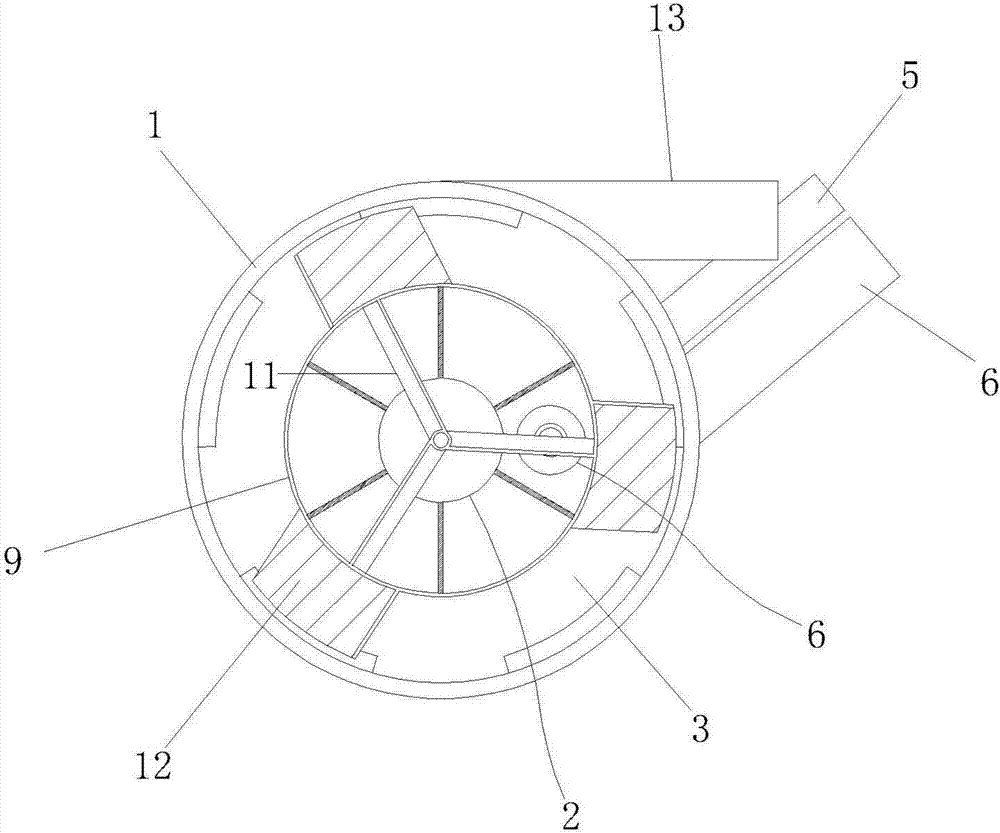

[0021] As shown in the accompanying drawings, a new type of silent dust removal spray device includes a housing 1, and the housing 1 is equipped with a discharge pipe 13 for discharging dirt. It is characterized in that the housing 1 is provided with an internal motor 4. The first chamber 2, the output shaft of the motor 4 passes through the first chamber 2 and is connected with the rotating part 100 provided with the impeller, and a connecting rod 10 is arranged between the bottom of the inner wall of the rotating part 100, and the top of the connecting rod 10 is connected with the output shaft Connected and the bottom is connected with the first impeller 11 through the connecting shaft 101, the outer wall of the rotating part 100 is also provided with the second impeller 12, the first impeller 11 discharges the wind downward and the blades of the second impeller 12 rotate in the opposite direction to the first impeller 11 , the first chamber 2 is fixedly covered with a cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com