An integrated equipment for cutting and edging of color steel tiles

A color steel tile and edging technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of easy injury of operators, high strength, scratches of operators, etc.

Active Publication Date: 2018-12-28

佛山市金泽科金属制品有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The thickness of the traditional color steel tile is relatively thin. For different roofs, the amount of material required is also different, so it needs to be cut. Since the color steel tile is metal, it needs to use traditional cutting tools. Traditional cutting There will be burrs on the edge, and the operator is easy to scratch during the handling process. Usually, after cutting, due to the large area of the color steel tile, it is necessary to manually grind the end face, which is strong and the depth of grinding is not easy. control, and there will be sparks splashing in the traditional cutting process, the operator is easily injured, so in order to solve these situations, it is necessary to design a cutting and grinding integrated equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

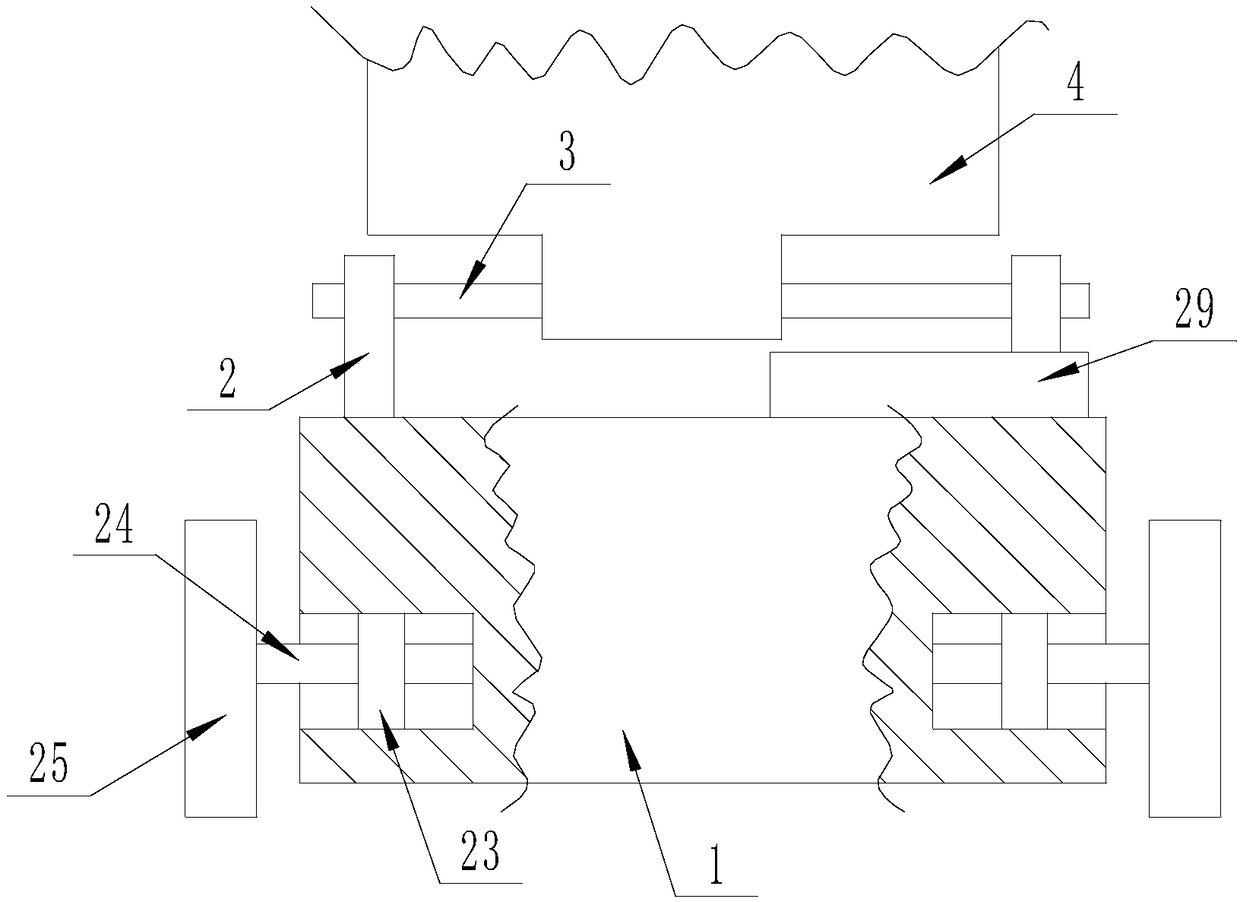

[0023] Embodiment 2: The electronically controlled push rod 6 can be replaced by a linear motor, which can also achieve the telescopic effect, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

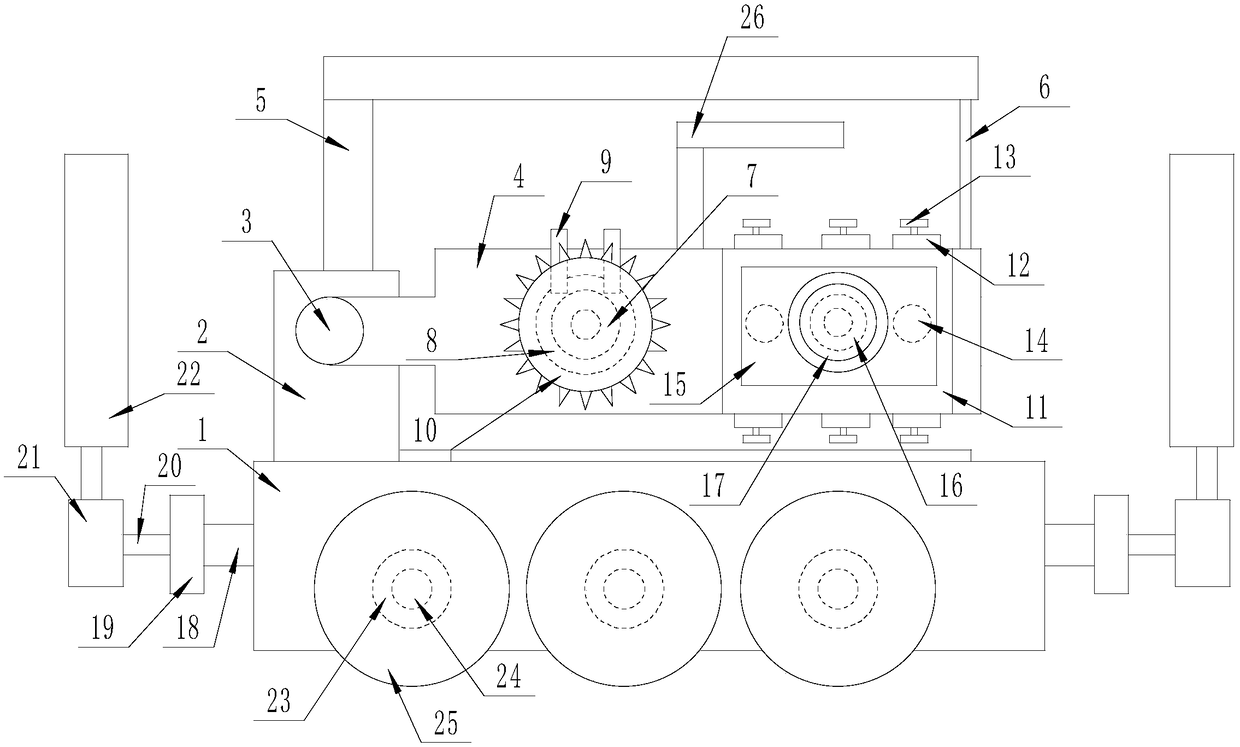

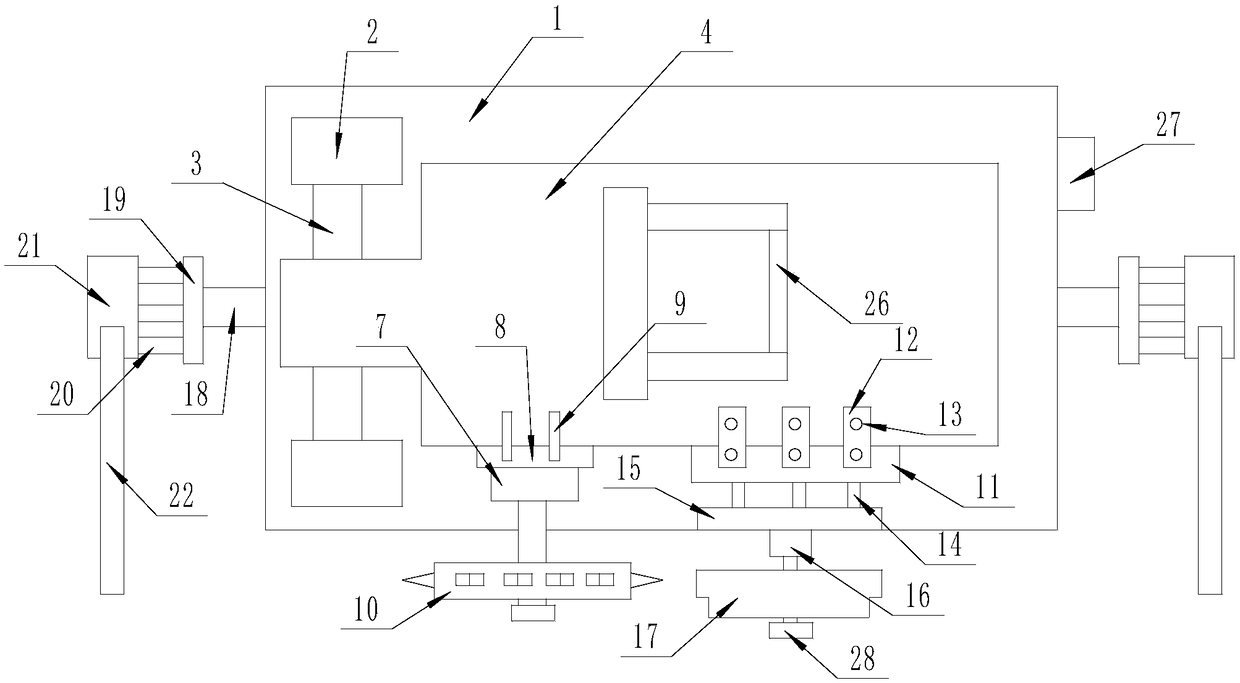

The invention discloses an integrated equipment for cutting and grinding color steel tiles, which includes a bar-shaped support base. One end of the upper surface of the bar-shaped support base is fixedly connected to a set of fixed protrusions. There is a load-bearing circular shaft in between. A strip-shaped swing plate is installed on the load-bearing shaft. One end of the side surface of the strip-shaped swing plate is equipped with a cutting mechanism. The other end of the side surface of the strip-shaped swing plate is equipped with a grinding mechanism. A set of The upper surface of the fixed protrusion is fixedly connected to the L-shaped fixed plate. A plurality of electronically controlled push rods are provided between the lower surface of the L-shaped fixed plate and the upper surface of the strip-shaped swing plate. The front and rear surfaces of the strip-shaped support base A moving mechanism is provided on the support base, and a protective mechanism is provided on the left and right surfaces of the strip support base. The beneficial effects of the present invention are that it is a device that is relatively convenient to operate, has good cutting effect, has good grinding effect on the cutting end face, is convenient for protecting workers, is convenient for controlling the grinding depth, reduces labor intensity, and is suitable for large-volume cutting.

Description

technical field [0001] The invention relates to the field of color steel tile cutting, in particular to an integrated equipment for cutting and edging of color steel tiles. Background technique [0002] Color steel tile is a kind of metal that is placed on the roof to replace the original asbestos tile to ensure that the house does not leak water. [0003] The thickness of the traditional color steel tile is relatively thin. For different roofs, the amount of material required is also different, so it needs to be cut. Since the color steel tile is metal, it needs to use traditional cutting tools. Traditional cutting There will be burrs on the edge, and the operator is easy to scratch during the handling process. Usually, after cutting, due to the large area of the color steel tile, it is necessary to manually grind the end face, which is strong and the depth of grinding is not easy. In addition, there will be sparks splashing in the traditional cutting process, and the op...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P23/04

CPCB23P23/04

Inventor 宋永全张佐福谢鸿斌

Owner 佛山市金泽科金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com