Efficient and automated 3D printing system suitable for batch production

A 3D printing, mass production technology, applied in the field of 3D printing, can solve the problems of low printing efficiency, waste of human resources, low efficiency, etc., to improve work efficiency, speed up printing, and achieve the effect of automated mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

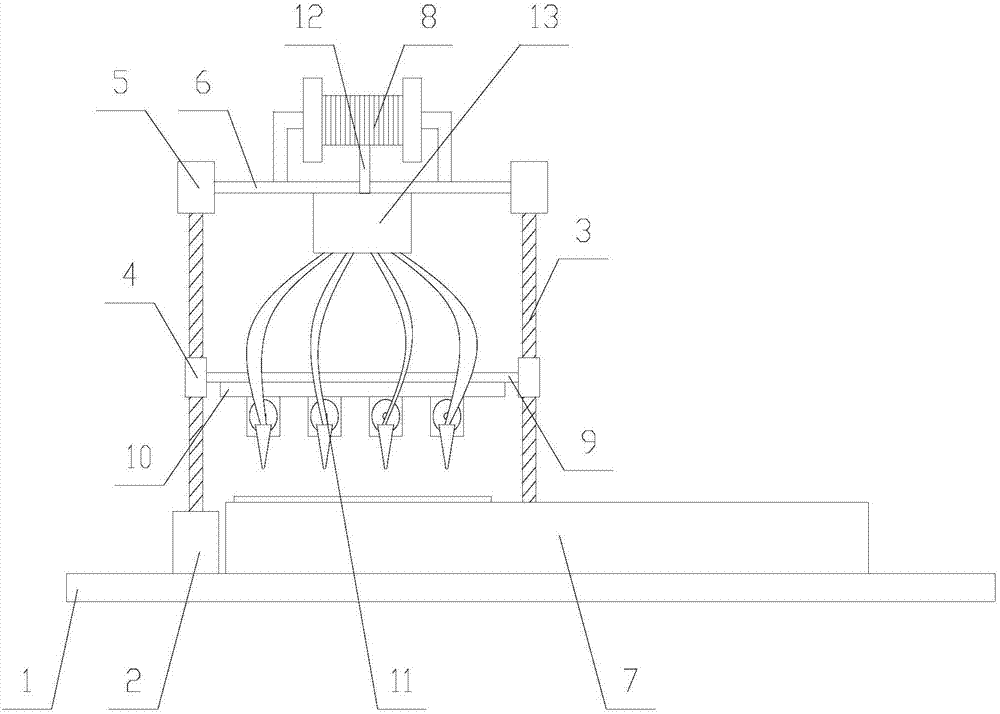

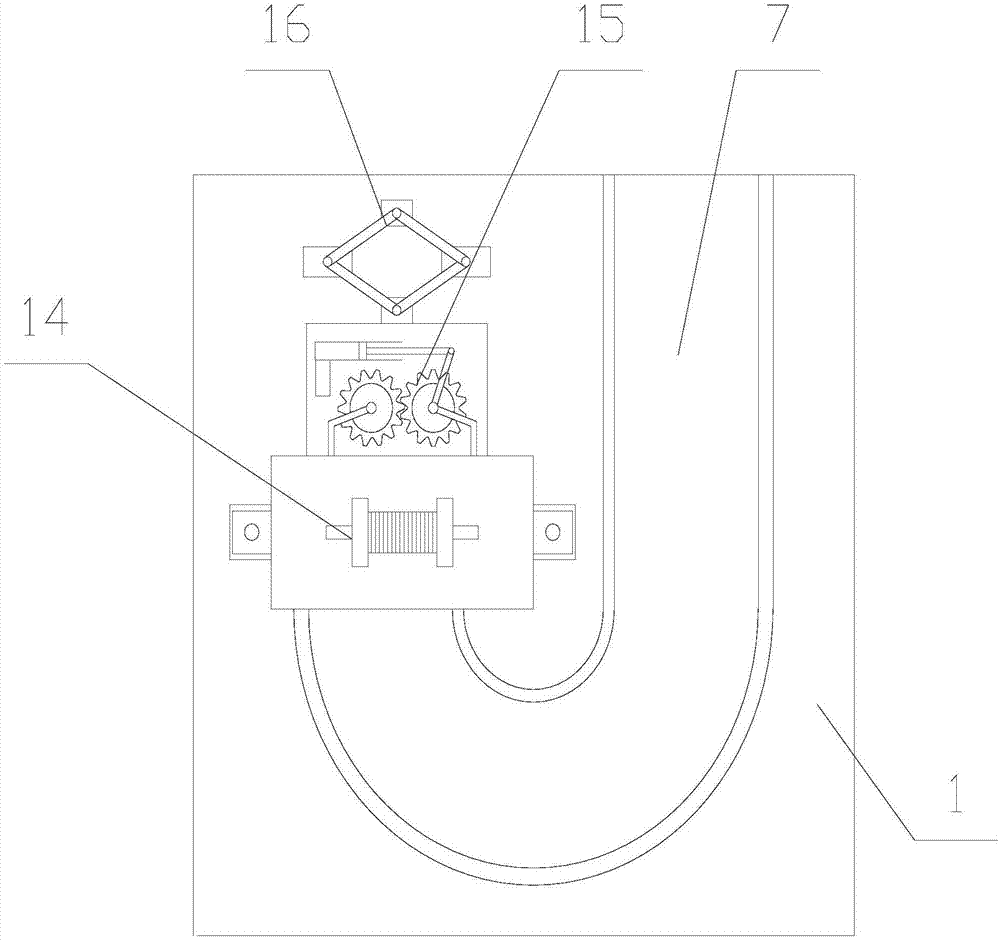

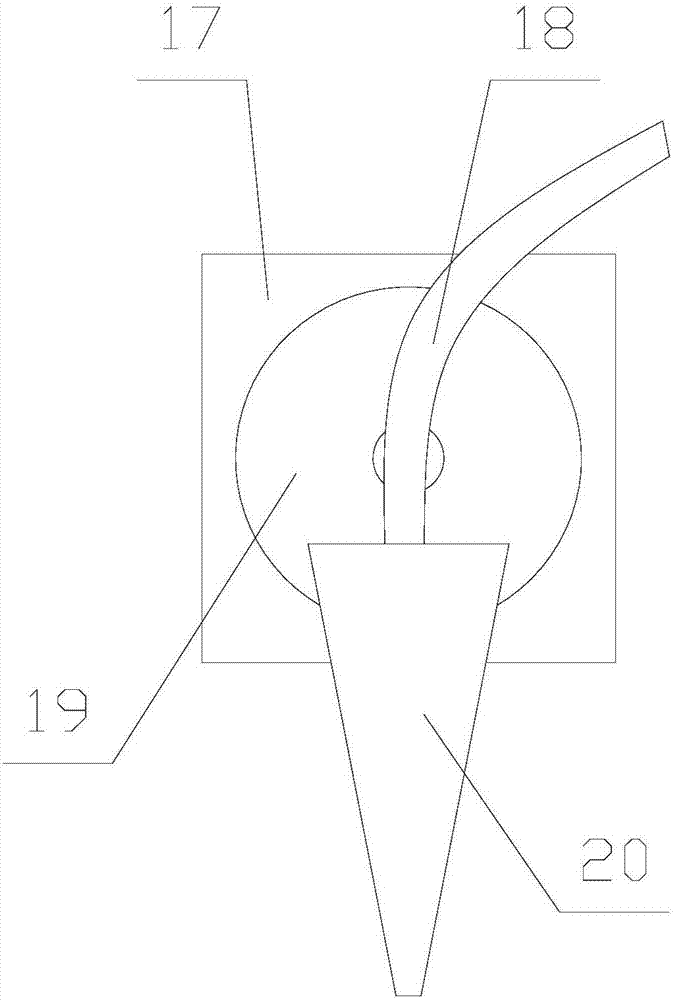

[0024] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0025] Such as Figure 1-Figure 5 As shown, a high-efficiency automated 3D printing system suitable for mass production includes a working platform 1, a printer 14 arranged above the working platform 1, a grabbing mechanism 15 and a pushing mechanism 16, and the grabbing mechanism 15 is arranged on the pushing mechanism 16 and the printer 14, the pushing mechanism 16 is connected to the grabbing mechanism 15 in transmission;

[0026] Described printer 14 comprises printing device and the lifting unit that is arranged on both sides of printing device, and described printing device comprises top plate 6, material tray 8, flat plate 9, planar moving mechanism 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap