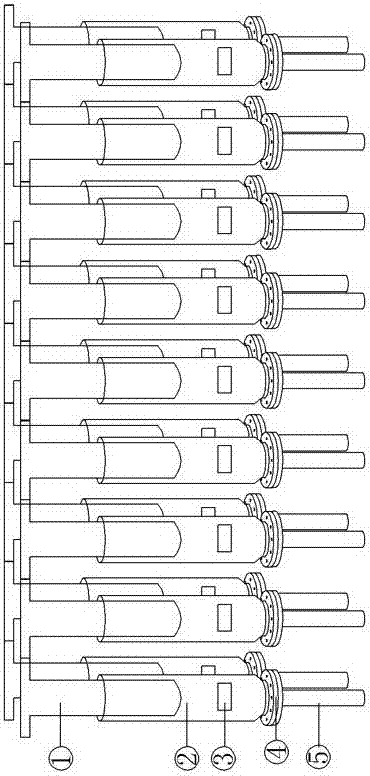

Eighteen-column rod-maker

A raw material barrel, circular technology, applied in the direction of manufacturing tools, presses, material forming presses, etc., can solve the problems of uneven heating and combustion of raw materials, waste of raw materials for production, insufficient dry distillation and evaporation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] In the figure, eighteen pressurized circular bodies ① are inserted into eighteen raw material barrels ② at the same time, and the raw materials that enter the eighteen raw material barrels ② from the eighteen feed ports ③ are simultaneously pressurized and encrypted. There is a feeding port ③ under each raw material barrel ②. Flanges ④ of the same size with an outer diameter of 0.18 meters and a thickness of 0.035 meters are connected to the lower ends of the eighteen raw material barrels ②, and the middle planes of the eighteen flanges ④ are vertically connected to each other with a length of 0.45 meters and an outer diameter of 0.12 meters. Circular die barrel body ⑤ of the same size. Eighteen flanges ④ and the middle of eighteen circular mold barrel bodies ⑤ have holes of the same size. Under the action of external high-strength pressure, the eighteen pressurized circular bodies ① pressurize and encrypt the production raw materials in the eighteen raw material barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com