FDY digitization automatic package matched logistics device

An automatic packaging and logistics technology, applied in the direction of packaging, packaging machines, transportation and packaging, etc., can solve the problems of large demand for personnel, low efficiency, high energy consumption, etc., to reduce safety risks, improve stability, avoid slipping and The effect of load-bearing parts slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

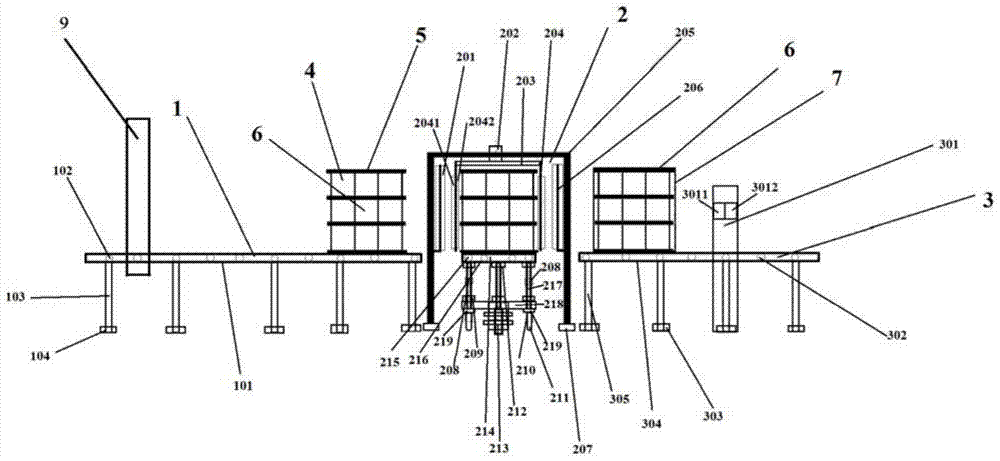

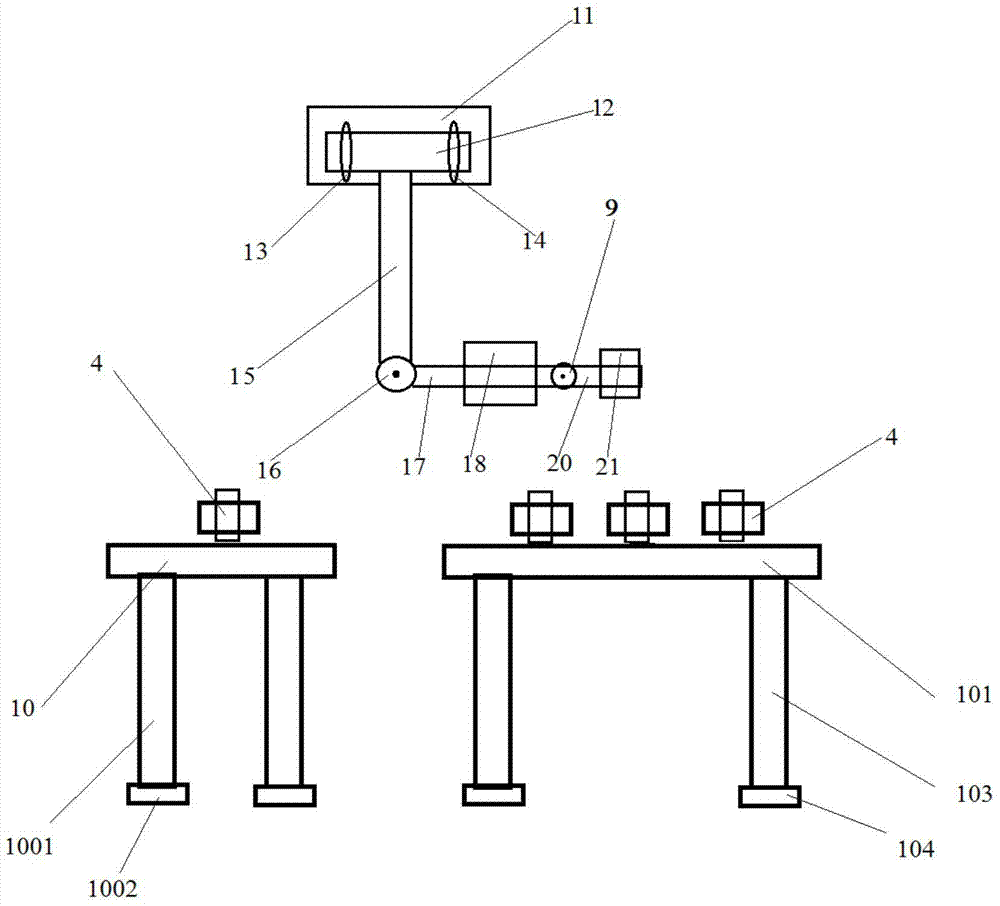

[0059] Please see attached figure 1 , a FDY digital automatic packaging supporting logistics device, FDY waste fiber and functional modified chip samples are melted through an intelligent online adding device to obtain a modified polyester melt, and the modified polyester melt is directly spun through the online adding device After the melt is mixed, it is melt-spun to obtain a polyfiber product, and the polyfiber product is transported to the FDY digital automatic packaging supporting logistics device, which is characterized in that the FDY digital automatic packaging supporting logistics device includes a silk cake from left to On the right are silk cake conveying system 9, silk cake conveying system 10, roller conveying system 1, packaging system 2 and information logistics system 3. In addition, the two systems of the silk cake conveying system 10 and the roller conveying system 1 are installed in parallel, and the distance between them is 15-30 cm. 1. The distance betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com