Conveying and folding mechanism used for fabric folding

A folding mechanism and fabric folding technology, which is applied in the direction of folding thin materials, thin material processing, transportation and packaging, etc., can solve the problems that the folding width cannot be adjusted according to the needs, and the folding requirements cannot be met, so as to achieve good folding effect and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

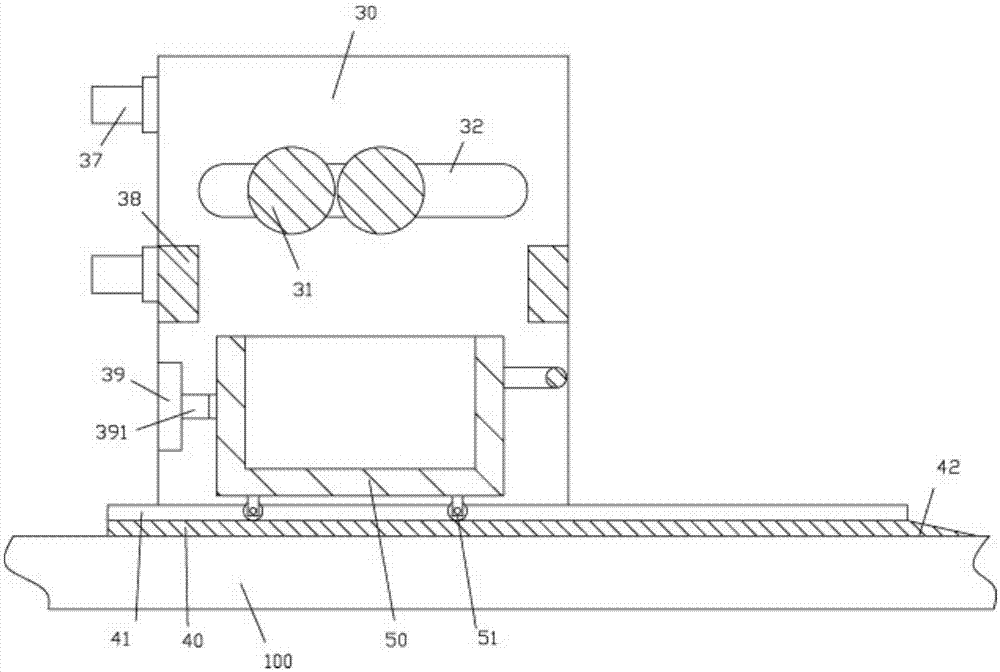

[0021] Examples, see e.g. Figure 1 to Figure 2 As shown, a kind of conveying and folding mechanism for cloth folding includes a main base plate 100, and the front and rear sides of the top surface of the main base plate 100 are fixed with folding support plates 30, and the main base plate 100 between the two folding support plates 30 is fixed on the main base plate 100. There are at least two parallel conveying rails 40, the top surface of the conveying rails 40 has a conveying groove 41, the discharging cart 50 is between the two folding support plates 30, and the bottom surface of the discharging cart 50 is provided with a plurality of wheels 51, The wheels 51 are inserted into the conveying groove 41;

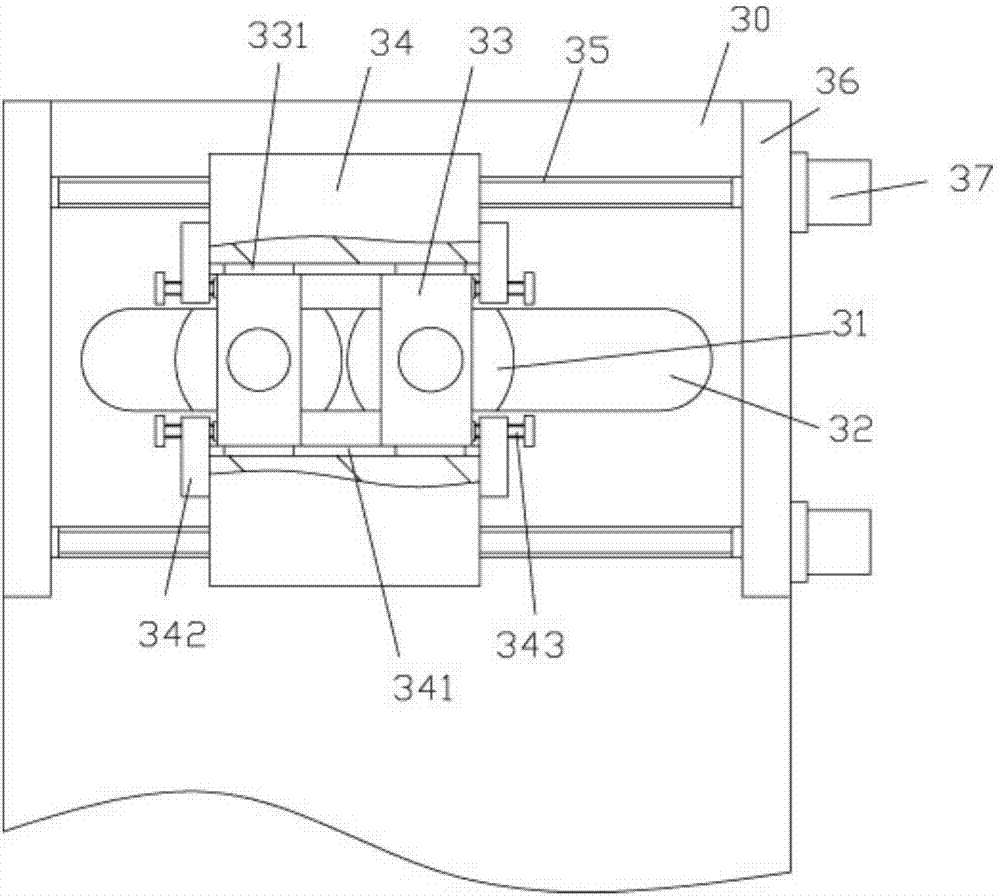

[0022] Two moving rollers 31 are arranged between the two folding support plates 30, and the two ends of the two moving rollers 31 protrude from the transverse slots 32 provided on the folding support plates 30 and are hinged on the corresponding folding moving blocks 33 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com