Aggregate grading design method for improving strength of cement-emulsified asphalt mixture

A technology of cement emulsified asphalt and design method, which is applied in the direction of climate change adaptation, coagulation pavement paved on site, construction, etc., which can solve the problem of limited constraints, aggregate gradation that cannot meet engineering requirements, and difficult control of gradation curves Problems such as smoothness and continuity, to achieve the effect of simple operation and less control variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The emulsified asphalt mixture gradation design method of this embodiment comprises the following steps:

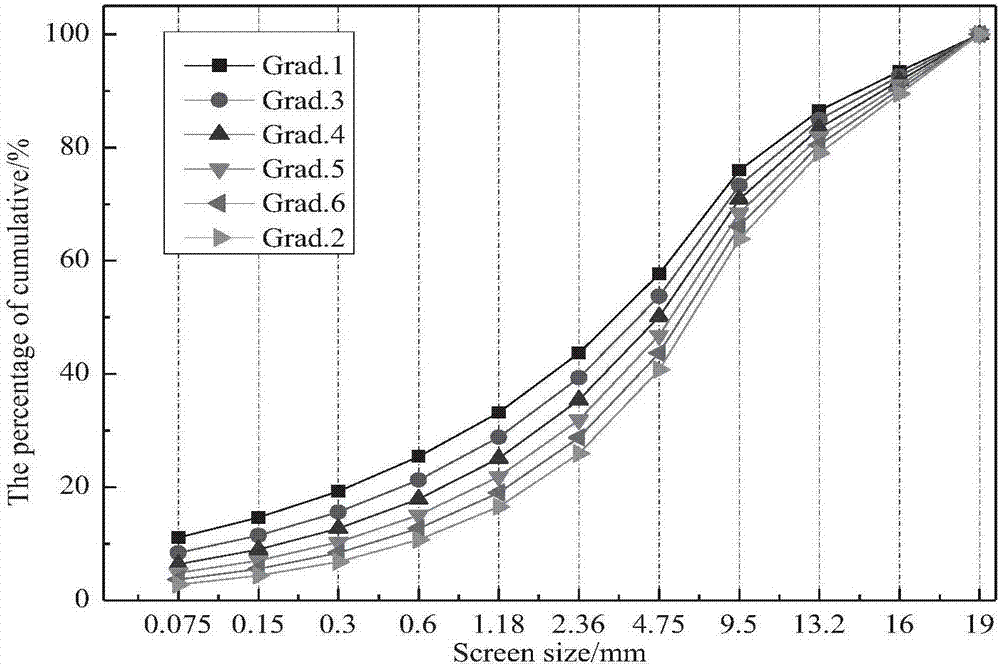

[0025] (1) In this embodiment, AC-16 is taken as an example, and the n value is taken as 5. The upper limit of the gradation corresponding to the multi-stage sieve size, the sieve size at each level and the lower limit of the gradation corresponding to the sieve size at each level are shown in Table 1;

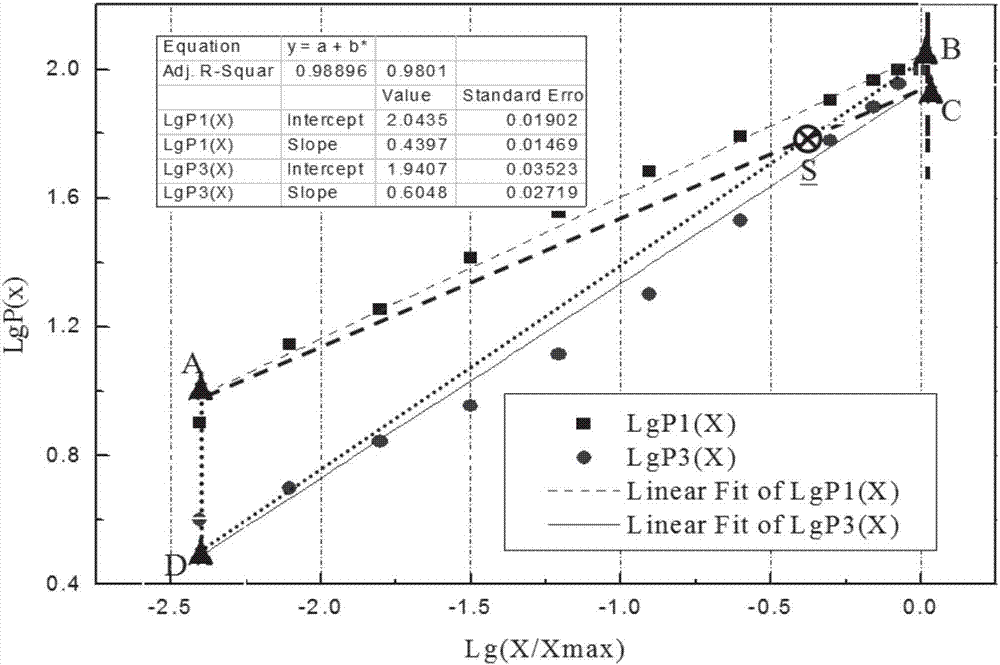

[0026] (2) Use the fractal theory to calculate the gradation cumulative pass percentage P(x) and x / x max Take double logarithms respectively (X is the sieve hole size, x max is the maximum sieve hole size), the results are shown in Table 1;

[0027] Table 1 Aggregate Grading (AC-16)

[0028]

[0029] (3) Use the least squares method to perform the best linear fitting on the gradation curve (the upper and lower limits of AC-16) under the logarithmic coordinates to obtain straight line 1 and straight line 2, and make a vertical line at the largest and smallest s...

Embodiment 2

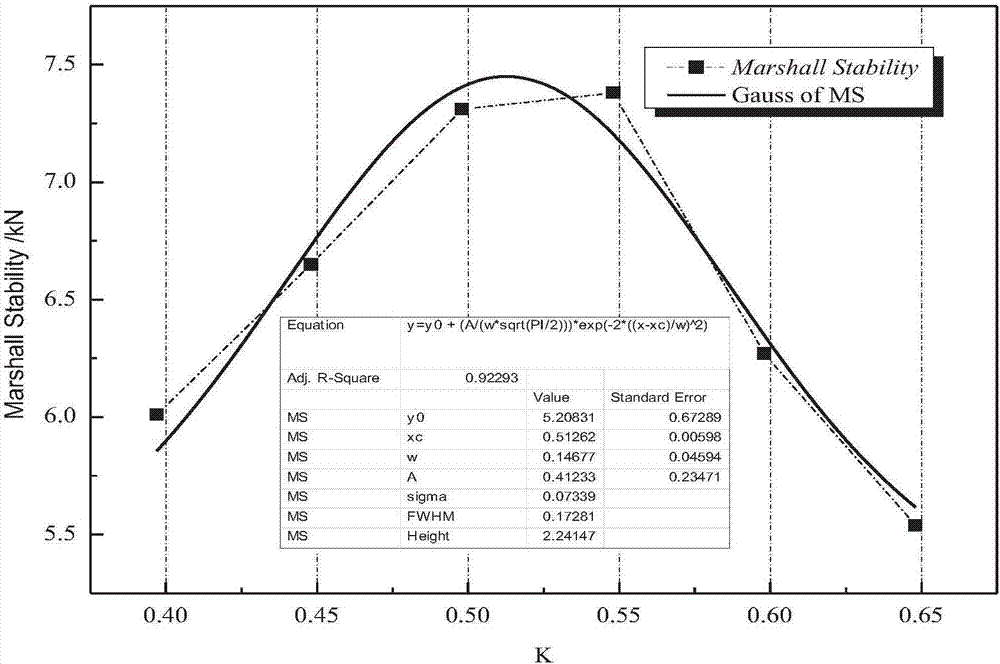

[0056] Design an AC-16 type aggregate gradation according to the principle of the trial algorithm, and then verify the difference in performance between the gradation designed by this method and the gradation designed by the method of the present invention. The advantages of the design gradation of the present invention are described.

[0057] This embodiment adopts trial algorithm, and the obtained results are shown in Table 6.

[0058] 9.5-16mm: 4.75-9.5mm: 2.36-4.75mm: 0-2.36mm: mineral powder = 28:24:18:25:5. The test materials are the same as in Example 1, and the mass ratio of emulsified asphalt:cement:limestone aggregate is 96:36:1164. The results of related performance experiments are shown in Table 7.

[0059] Table 6 synthetic gradation

[0060]

[0061] Table 7 The parameter index of synthetic graded mixture

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com