Concrete structure and method for leveling prefabricated concrete pavement slab

A prefabricated assembly and prefabricated concrete technology, applied in the direction of roads, roads, road repairs, etc., can solve problems such as unfavorable control of construction quality and construction progress, taking up a lot of time and manpower and material resources, shortening maintenance time, etc., to save construction period and cost. , Reduced process, not easy to overturn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

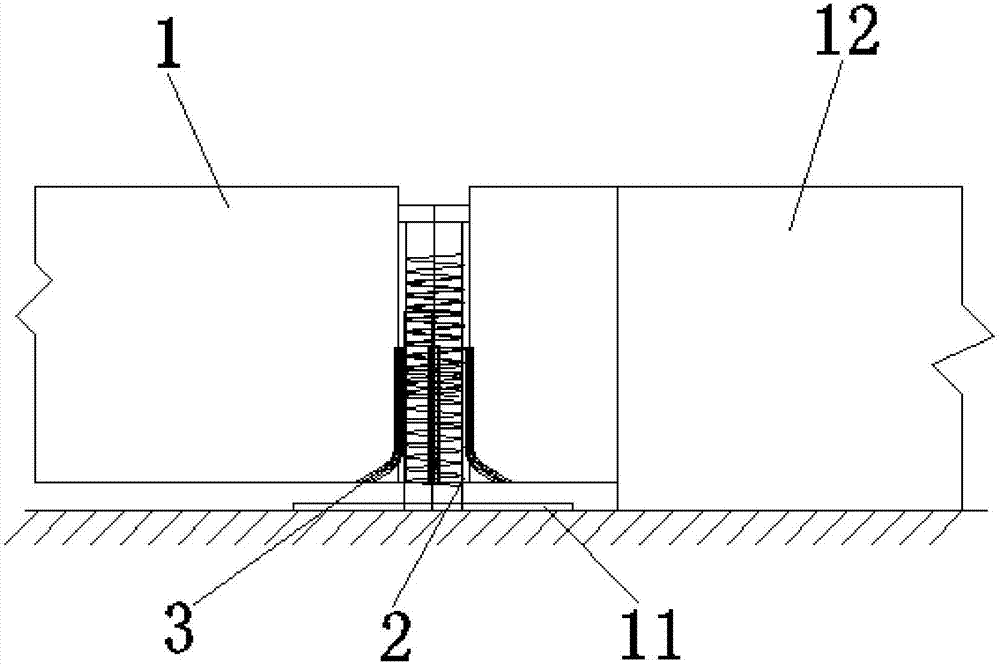

[0027] Such as Figure 1-5 Shown, a kind of method for leveling prefabricated concrete road slab comprises the steps:

[0028] S1: Screw the plug hole bolt 4 into the upper and lower ends of the claw-shaped embedded part 2 to seal the claw-shaped embedded part 2;

[0029] S2: placing the claw-type embedded part 2 on the bottom of the precast concrete form 1, and pouring concrete into the precast concrete form 1;

[0030] S3: After the concrete is initially set in the precast concrete formwork 1, the plug hole bolt 4 is removed;

[0031] S4: Screw the hoisting bolt 4 into the claw-type embedded part 2, and hoist the precast concrete formwork 1 to a preset position through the hoisting bolt 7;

[0032] S5: Remove the lifting bolt 7, screw the leveling bolt 10 into the claw-type embedded part 2, and level the precast concrete formwork 1 to a preset height through the leveling bolt 10, the A certain gap is formed between the prefabricated concrete formwork 1 and the original co...

Embodiment 2

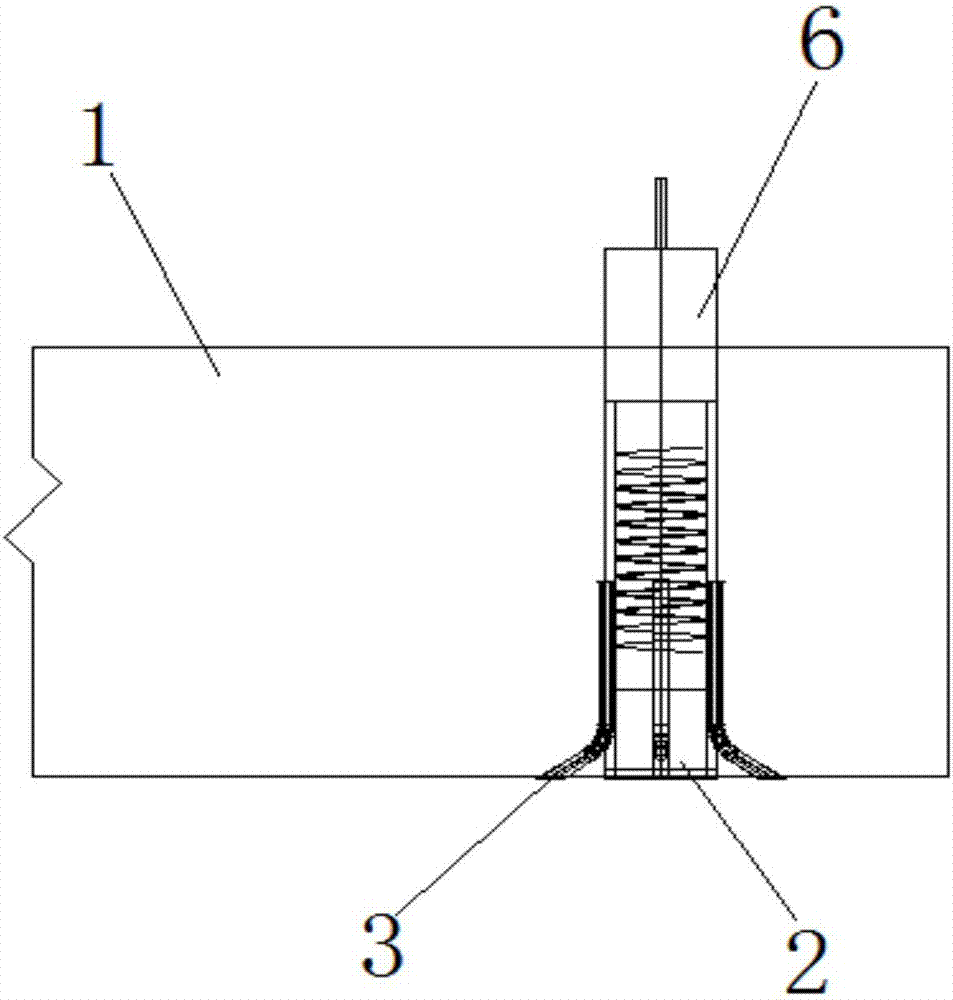

[0037] Such as Figure 1-5 As shown, the concrete structure includes a precast concrete formwork 1, and claw-type embedded parts 2 are arranged in the precast concrete formwork 1.

[0038] The claw-shaped embedded part 2 is a steel round pipe with internal threads.

[0039] A plurality of claw-shaped support structures 3 are welded to the lower part of the steel circular tube.

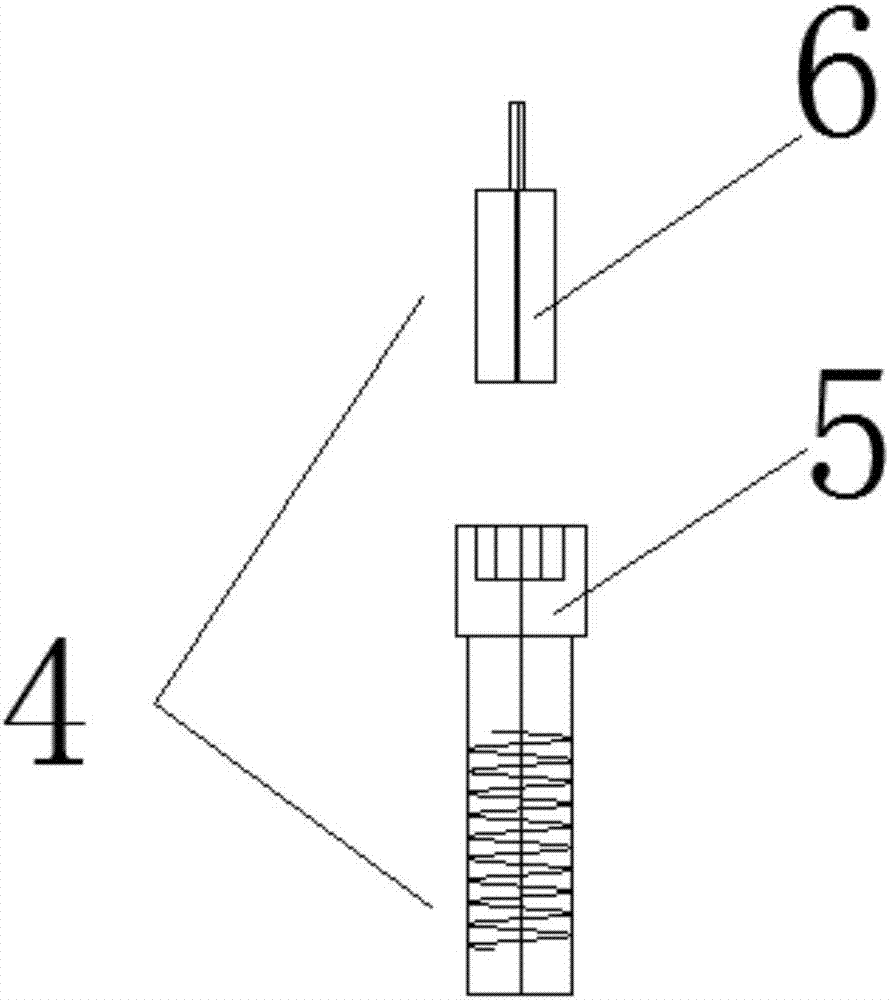

[0040] The claw-shaped embedded part 2 is adapted to the plug hole bolt 4, and the plug hole bolt 4 is composed of a steel hexagon socket bolt 5 and a plastic regular hexagon plug hole 6.

[0041] The claw-type embedded part 2 is adapted to the lifting bolt 7, and the lifting bolt 7 is composed of a bolt 8 and a lifting ring 9 welded on the top of the bolt.

[0042] The claw-shaped embedded part 2 is adapted to the leveling bolt 10, and the leveling bolt 10 is a regular hexagonal bolt inside.

[0043] In the specific technical solution of the present invention, the main body of the claw-shaped embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com