Vapor Recovery System for Steam Wax Remover

A technology of recovery system and wax removal vehicle, which is applied in the direction of cleaning equipment, wellbore/well components, isolation devices, etc., can solve the problems of wasting steam, large energy waste, and low efficiency, and achieve the effect of reducing waste and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

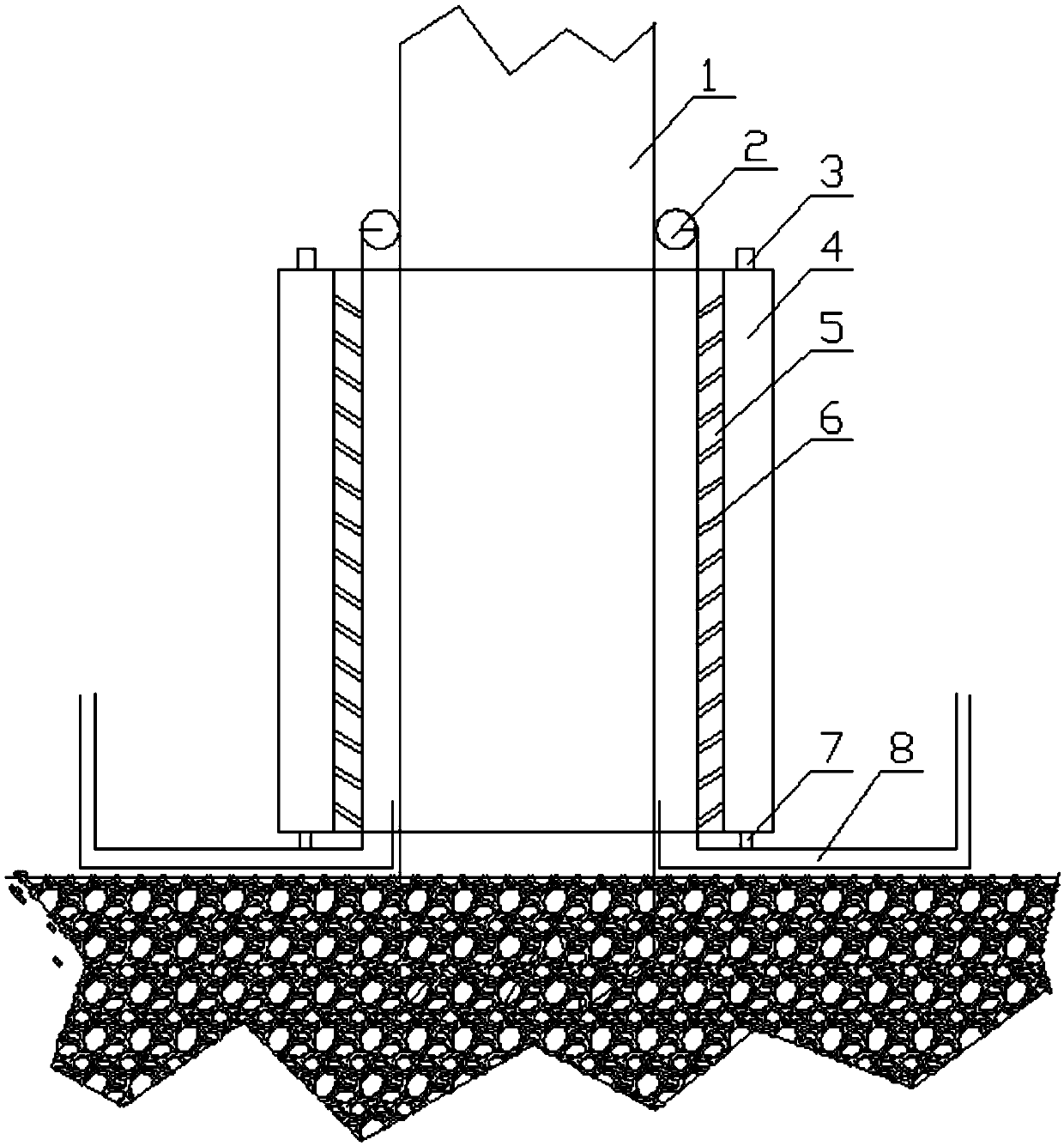

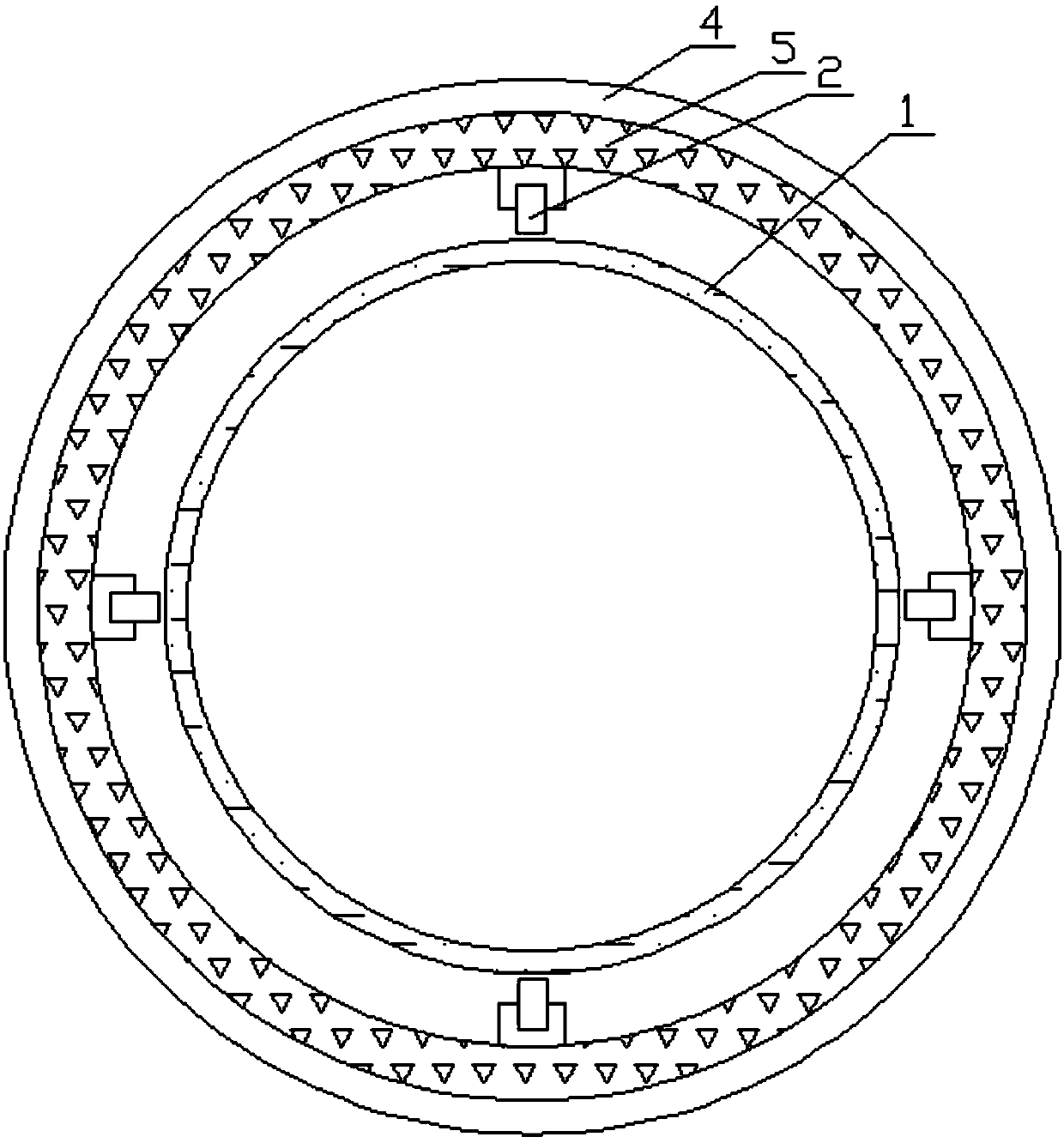

[0021] Such as figure 1 and figure 2 As shown, the steam recovery system of the steam wax removal vehicle includes an oil suction pipe 1, and also includes a casing and a steam insulation layer 5, both of which are cylinders, and the steam insulation layer 5 is placed inside the casing, A cavity 4 is formed between the shell and the steam isolation layer 5, and the cavity 4 is sealed up and down; the upper surface of the cavity 4 is provided with a plurality of steam inlets 3; the wall of the steam isolation layer 5 is uniformly provided with A plurality of steam injection holes 6; there is a gap between the inner side of the steam isolation layer 5 and the oil suction pipe 1, and a steam recovery pipe 8 on the wall of the oil suction pipe is arranged at the bottom of the gap.

[0022] The central axis of the steam injection hole 6 inside the steam isolation layer 5 is higher than the central axis of the steam injection hole 6 outside the steam isolation layer 5; the angle r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com