Core pulling rivet with internally-arranged lock ring

A technology of blind rivets and lock rings, which is applied to rivets, screws, threaded fasteners, etc., which can solve the problems of easy fall off of lock rings and failure of lock ring installation, and achieve the effect of simple accessories, improved reliability and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings.

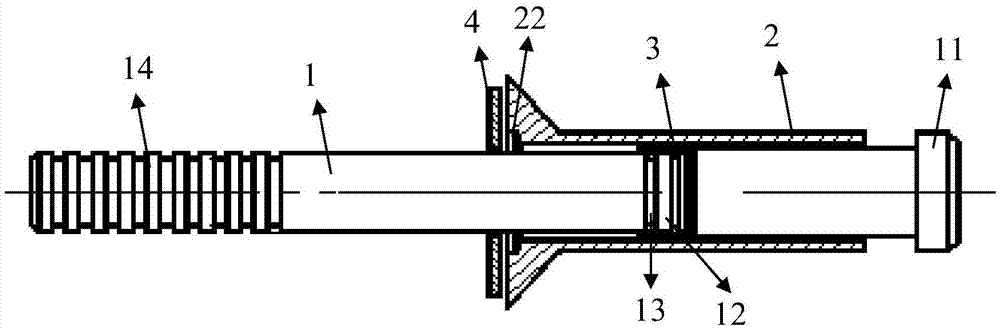

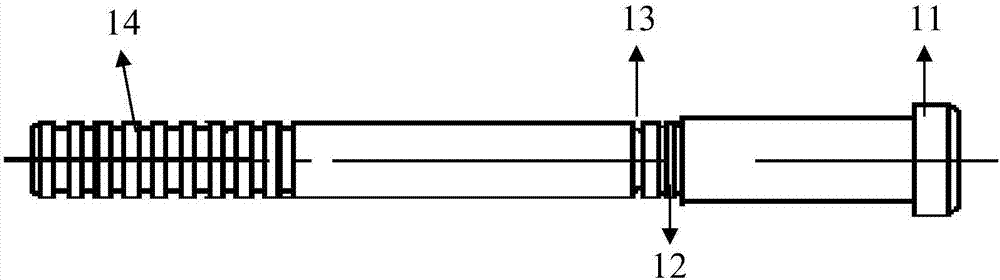

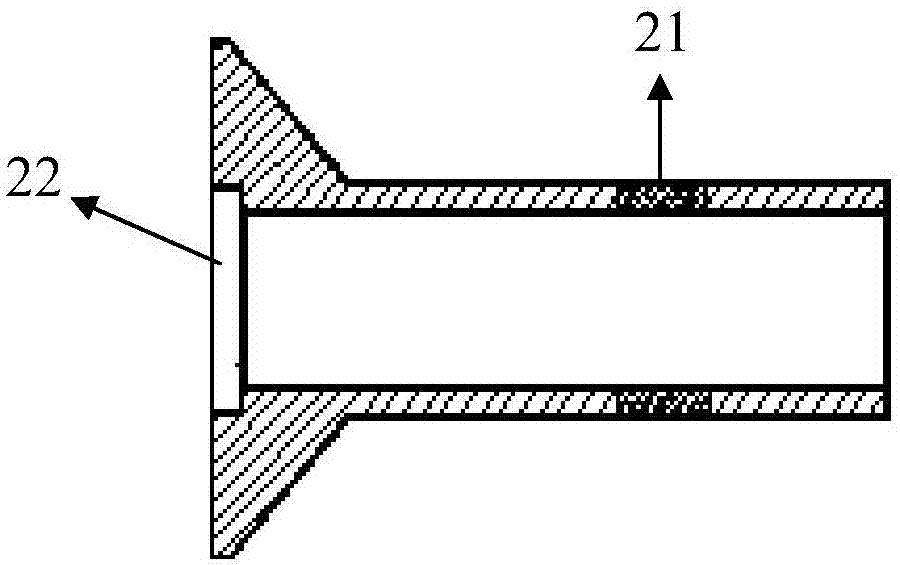

[0025] The structure created by the present invention is as figure 1 As shown, it includes a mandrel 1, a nail sleeve 2, a lock ring 3 and an anvil 4; The lock ring groove 12, the tail is provided with a clamping section 14; the lock ring groove 12 is located between the limiting platform 11 and the broken neck groove 13; the nail sleeve 2 is set on the core rod 1, The tail of the nail sleeve 2 can be limited by the limit platform 11 of the core rod 1, the length of the nail sleeve 2 is greater than the length of the distance between the step surface of the limit platform 11 and the broken neck groove 13, The nail sleeve 2 is provided with a section of deformable section 21. When the nail sleeve 2 is in the limiting position limited by the limiting platform 11, the deformable section 21 is located between the limiting platform 11 and the lock ring groove 12. between;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com