A high-precision explosion source location device for offshore platform tests

An offshore platform, high-precision technology, applied in the direction of measuring devices, blasting, impact testing, etc., can solve the problems of large deflection of slender rods, non-reusable operation, broken positioning devices, etc., to reduce installation costs and simple structure , the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

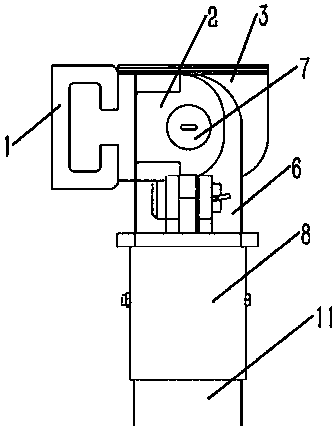

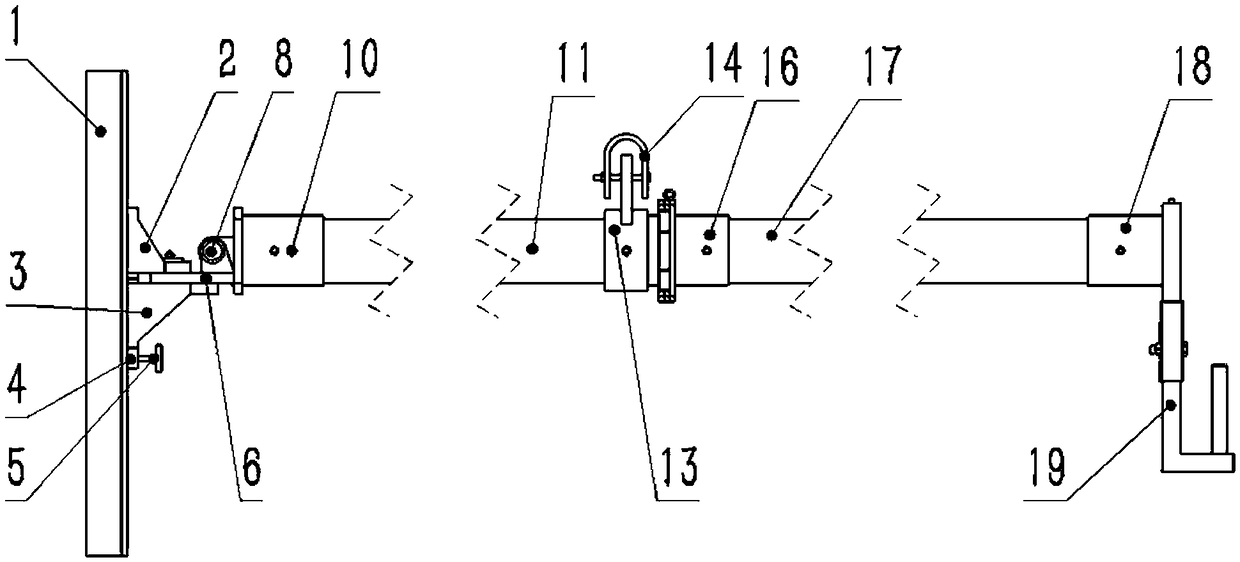

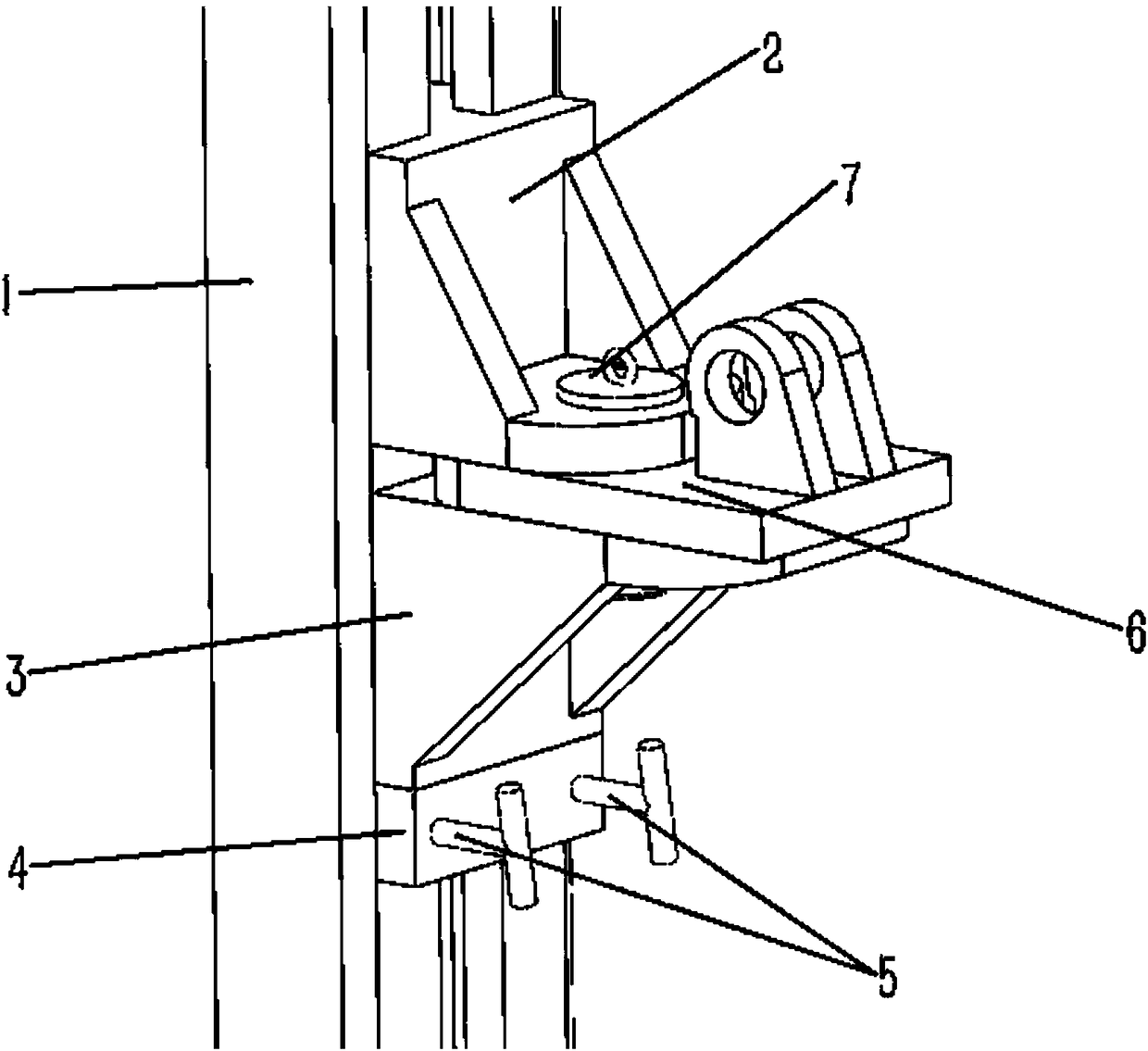

[0021] combine Figure 1 to Figure 8 , a device for mechanical positioning of a high-precision explosion source for an impact platform sea test of the present invention includes a fixed slide rail 1, an upper end slider 2, a lower end slider 3, a moving positioning block 4, a slider fastening bolt 5, a rotating Block 6, end pin 7, first-level connecting cylinder 8, movable pin 9, nail penetration 10, first-level extension rod 11, connecting piece 12, cushioning piece positioning piece 13, U-shaped cushioning rubber 14, hinge plate 15, two The first-stage connecting cylinder 16, the second-stage extension rod 17, the end mount 18, the buoy support 19, bolts, nuts, etc.; Sliding track: the upper end slider 2 and the lower end slider 3 are installed on the fixed slide rail, and can move freely in the track of the fixed slide rail 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com