Ceramic tile flatness measuring device

A measuring device and flatness technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of time-consuming and labor-intensive, affecting the aesthetic effect, low paving efficiency, etc. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

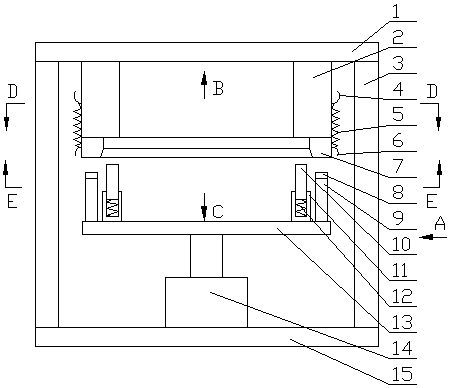

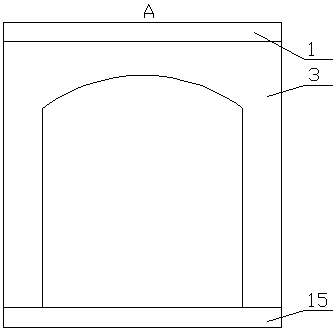

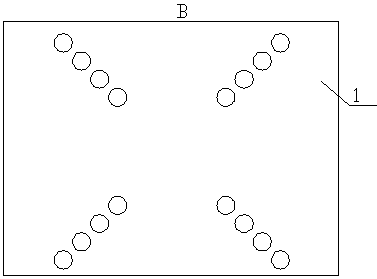

Embodiment Construction

[0021] The design principle of the present invention is developed based on the characteristics of the technical process of tile laying. When laying tiles, the joint corners of each adjacent four tiles are set as leveling points. In this way, if the flatness of each tile is very high , the flatness of the overall paving can be guaranteed, but if the flatness of some tiles is not up to standard, even if the flatness of the joint corners of every four adjacent tiles meets the standard, the edge joints of adjacent tiles may There will be an uneven effect. This kind of uneven defect is difficult to find visually without comparison with reference objects before paving, but after paving, it is very easy to see if there is a comparison between adjacent tiles. easily detected by the naked eye. Therefore, the measuring device of the present invention, before paving and pasting, screens out the tiles whose edge flatness is not up to standard by comparison, and pre-treats them in advance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com