Rapid elimination method for shaft forging flaw detection phantom wave

An ultrasonic and phantom technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, process detection response signals, instruments, etc., can solve the problems of increasing losses, misjudgments, etc., to reduce losses, improve misjudgments, and improve flaw detection accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

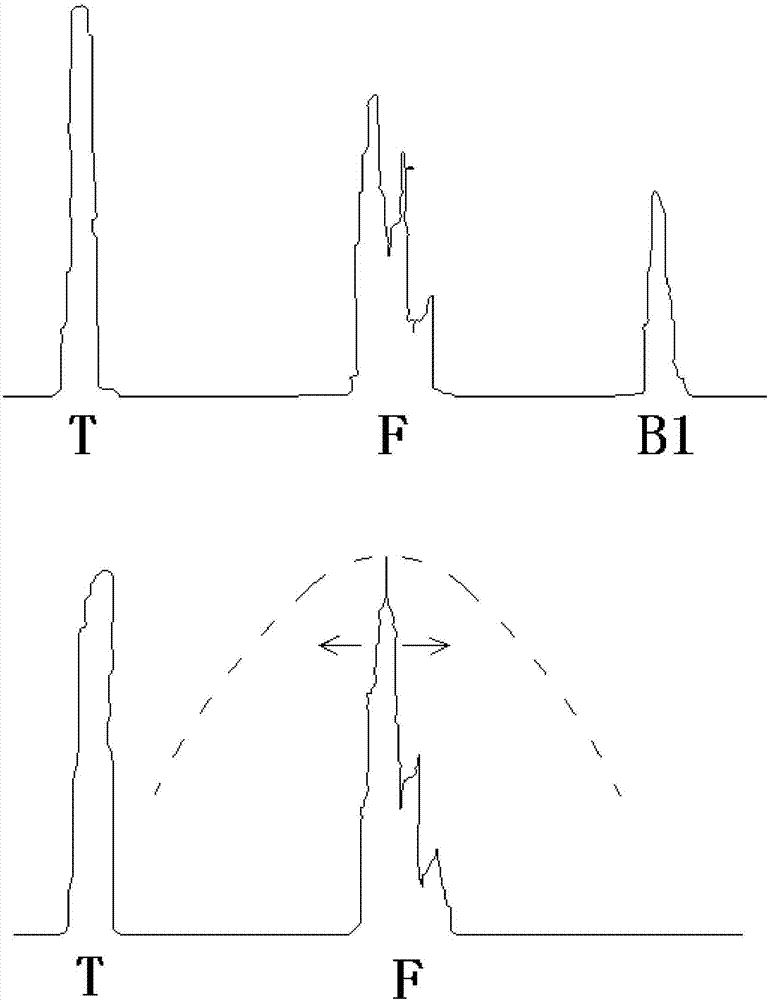

[0030] When using a 2-2.5M probe to radially detect shaft forgings, phantom waves may appear on the oscilloscope of the ultrasonic flaw detector. It is enough to detect the displayed parts. If the wave F on the oscilloscope disappears, the wave F is a fantasy wave; otherwise, the wave F is a defect wave, indicating that the shaft forging has defects and should be replaced or repaired in time.

Embodiment 2

[0032] In general flaw detection, adjust the sound path of the primary bottom wave B1 to the eighth grid of the oscilloscope. When the wave F is found to be displayed before the primary bottom wave B1, adjust the sound path knob of the ultrasonic flaw detector to increase the sound path to 1680mm. If the wave F on the oscilloscope disappears, the wave F is a fantasy wave; otherwise, the wave F is a defect wave, indicating that the shaft forging is defective and should be replaced or repaired in time.

[0033] The invention discloses a method for rapidly eliminating phantom waves in ultrasonic flaw detection of shaft forgings. When there is a signal wave F that is not sure whether it is a phantom wave or a defect wave, it adopts the method of adjusting the repetition frequency of the flaw detection instrument, changing the frequency of the probe and increasing the detection sound path. Any one of the three detection methods can detect whether the wave F is a defect wave. These t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com