NURBS curved surface reconstruction-based geometric error representation method

一种几何误差、曲面重构的技术,应用在几何CAD、仪器、计算等方向,能够解决系统精度无法满足设计要求、无法加工表面几何误差信息统一、损失装配仿真分析精度等问题

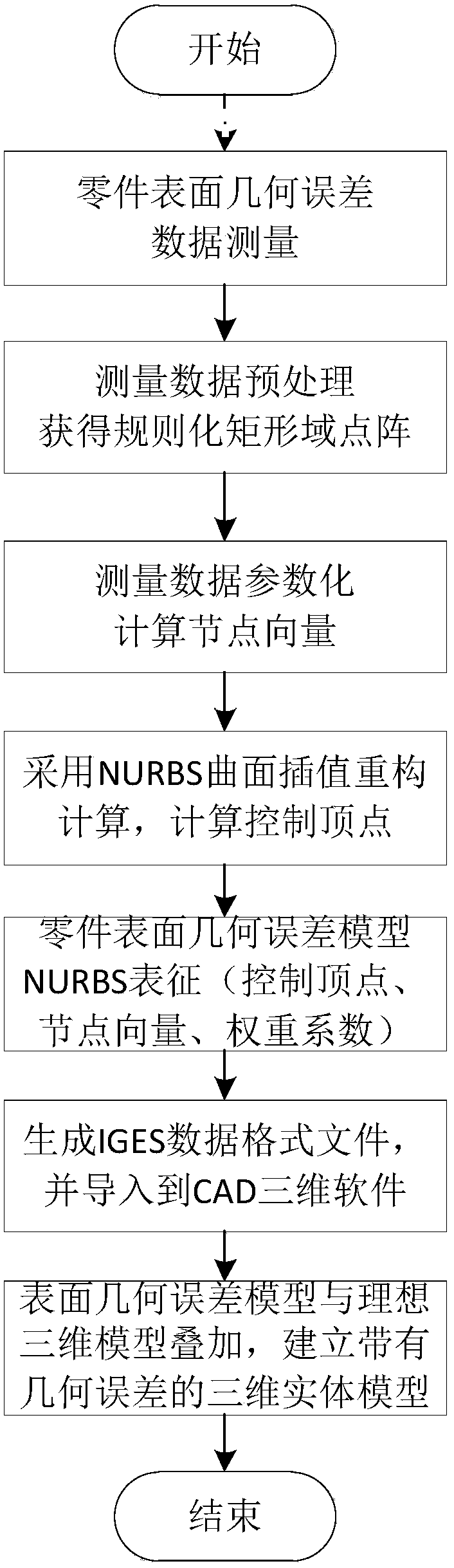

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

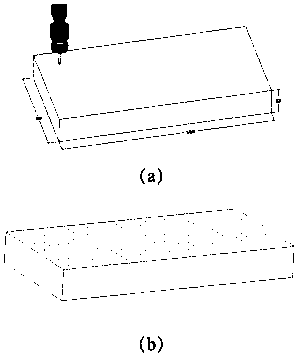

[0031] (1) To measure the geometrical error data of the surface of the part, using appropriate digital measurement methods to obtain accurate actual part surface data is the most basic link in the modeling of geometrical error. Use high-precision measuring instruments such as three-coordinate measuring machines to measure parts. The actual surface is machined, and the measurement data of the double-ordered topological rectangular mesh feature on the surface of the machined part is obtained;

[0032] (2) Preprocessing of measurement data, performing probe radius compensation on the measured data, and eliminating bad points to obtain regular measurement data points on the surface of the part, that is, the shape value point Q k,l (k=0,1,…,n; l=0,1,…,m), rectangular field value The number of data points in two directions of grid points is n+1, m+1;

[0033] (3) Randomly determine the degree of NURBS surface as p and q, and the shape point Q k,l The weight factor is w k,l =1;

...

Embodiment 2

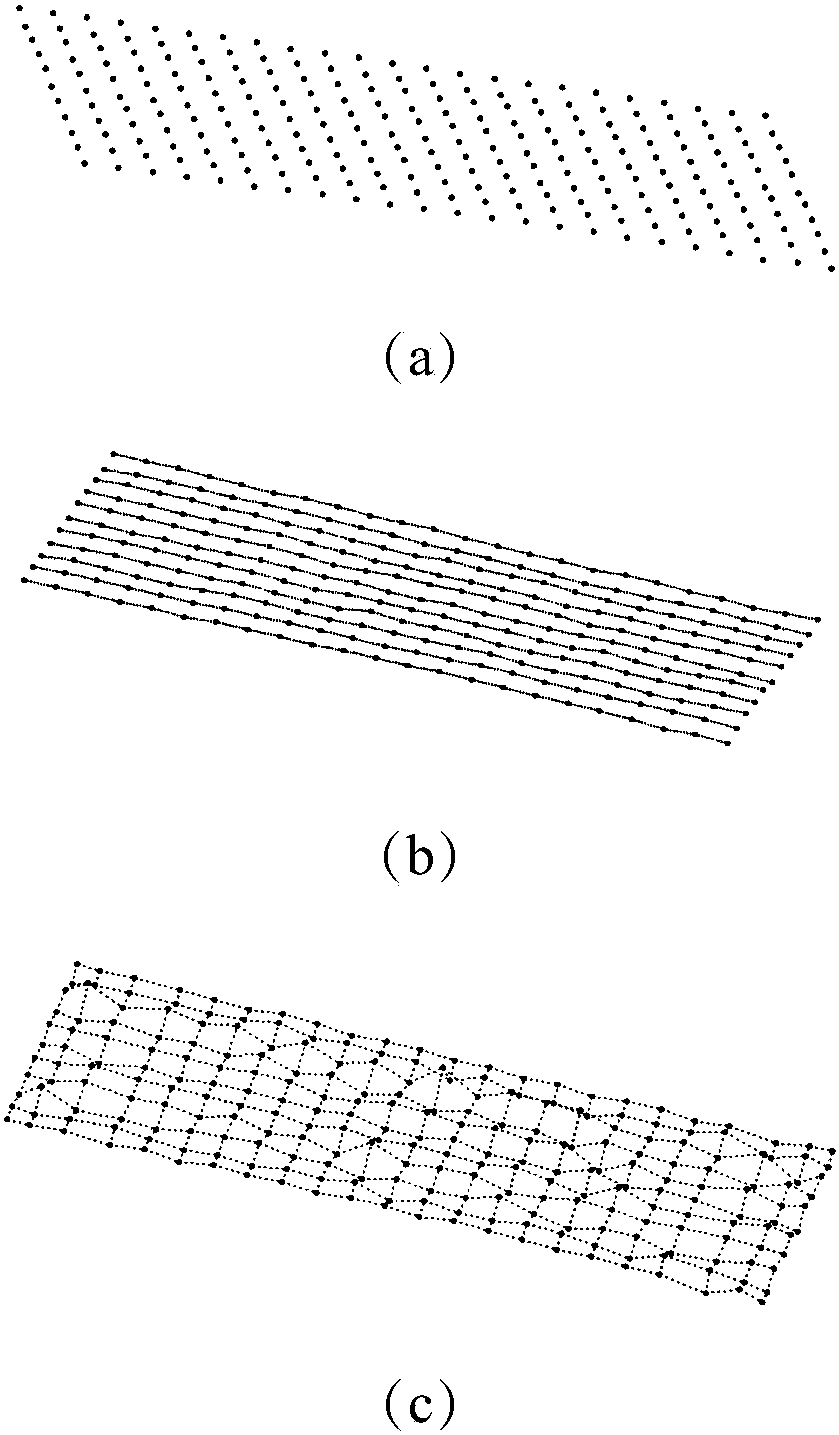

[0058] (1) Using a high-precision three-coordinate measuring machine to collect data on a milling plane on a flat part, the size of the flat part is 120cm×60m×15m, the three-coordinate measurement accuracy is: (2.2+L / 330)um, and the measurement method is: For contact measurement, the probe radius of the measuring probe used in the three coordinates is 1.5mm. The sampling interval is: 5mm, and the three-dimensional coordinates XYZ of 253 measurement points in 23 rows and 11 columns with topological rectangular grid features are obtained, such as figure 2 shown;

[0059] (2) Preprocessing of the measurement data, performing probe radius compensation on the measured data, and eliminating the bad points to obtain the regularized measurement data points on the surface of the part, that is, 23 × 11 type value points Q k,l (k=0,1,...,n; l=0,1,...,m), n=22, m=10, such as figure 2 (b);

[0060] (2) Determine the degree of the NURBS surface as p=3 and q=3, and the type value point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com