Device for repeatedly splicing outdoor cable terminal station

A splicing device, outdoor cable technology, applied in the direction of cable terminals, etc., can solve problems such as affecting the normal operation of the original line, long construction period, power failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

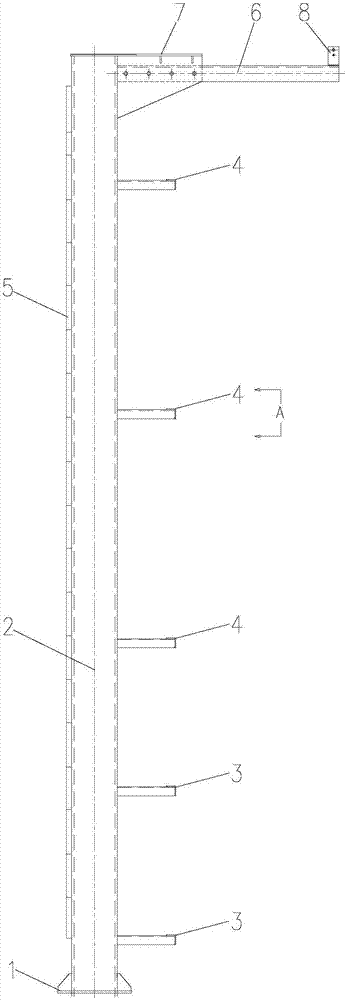

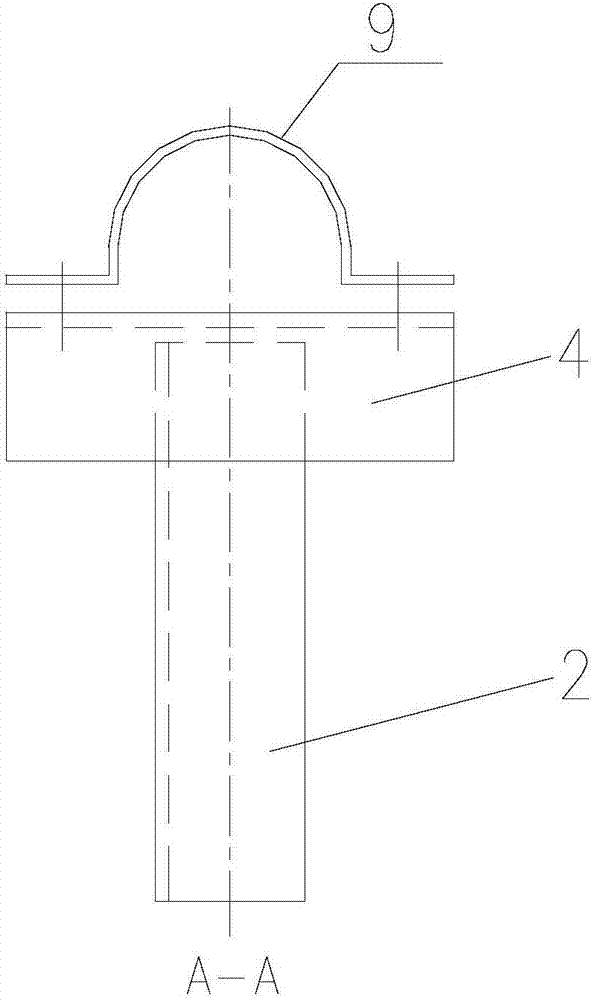

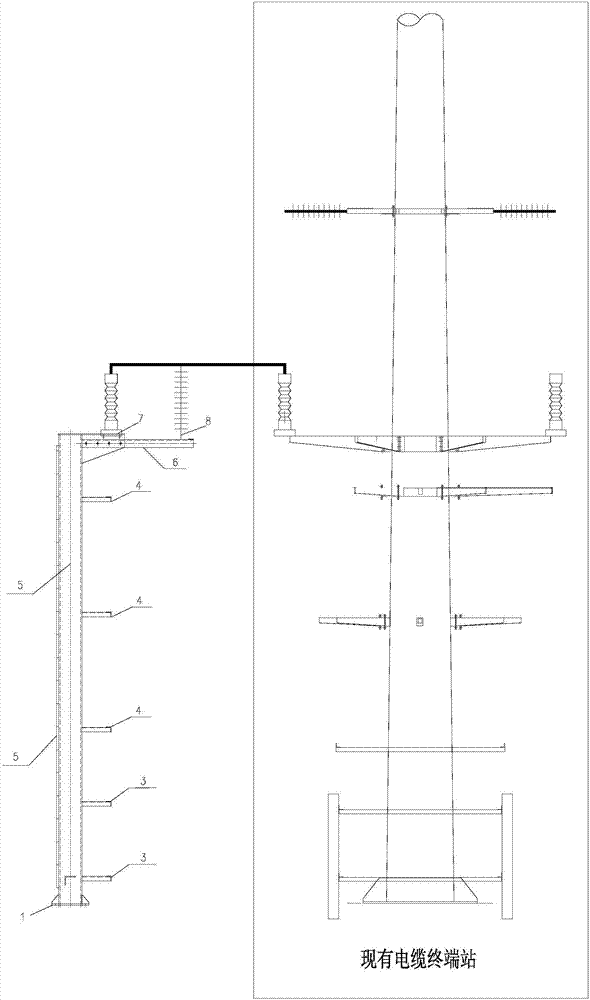

[0017] according to figure 1 As shown, a multiple splicing device for an outdoor cable terminal station, including a column steel pipe 2, is characterized in that: the bottom end of the column steel pipe 2 is provided with a bottom flange 1, and the bottom flange 1 is used to fix the column steel pipe 2. The outer diameter of the bottom flange 1 is 650mm, and a ladder 5 and cables are provided along the column steel pipe 2. The ladder 5 is convenient for construction and maintenance personnel to check up and down. The cable is wrapped with a protective tube, and the protective tube is used for To protect the cable, the protective tube is fixed by the protective tube fixing bracket 3, and the cable is fixed by the cable fixing bracket 4, specifically, the cable passes through the engineering hoop 9 on the cable fixing bracket 4 and is fixed on the cable fixing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com