Tower structure of vertical axis wind turbine rotor

A wind turbine, vertical axis technology, applied in the field of tower structure, can solve the problems of reduced rotor airflow efficiency, affecting rotor blade airflow, etc., and achieves the effects of increasing mechanical power, reducing on-site fabrication and installation costs, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

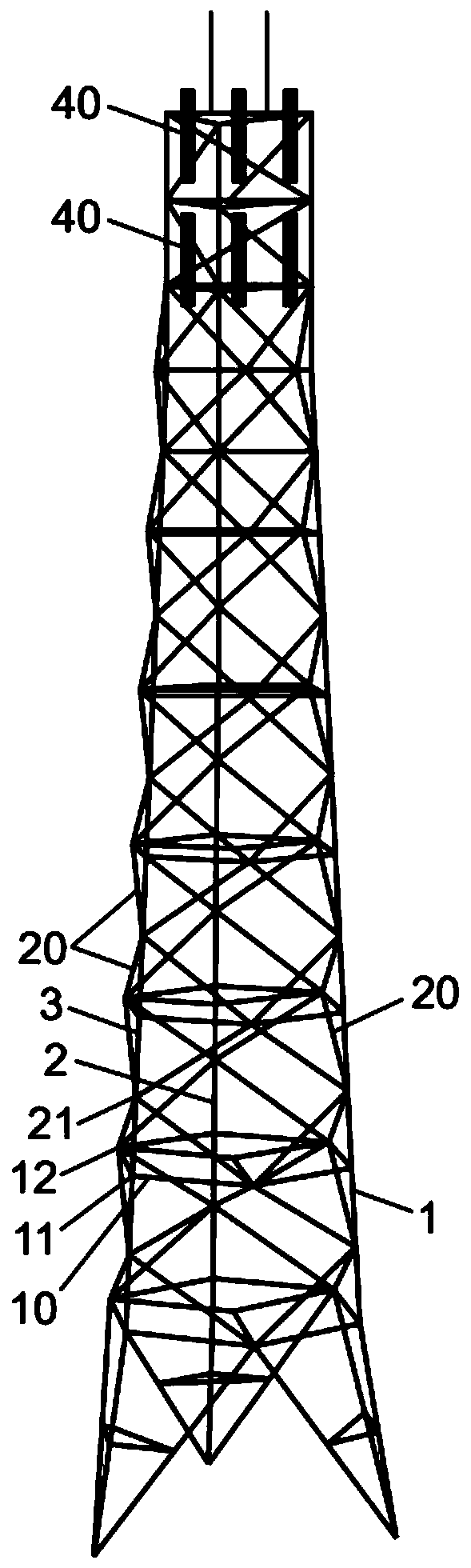

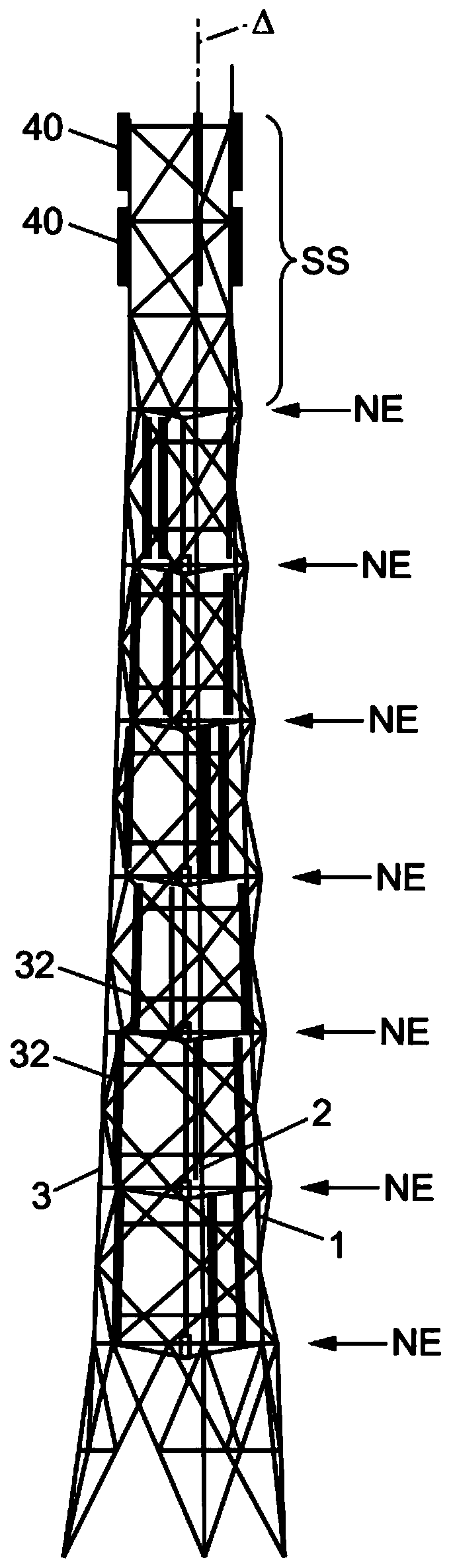

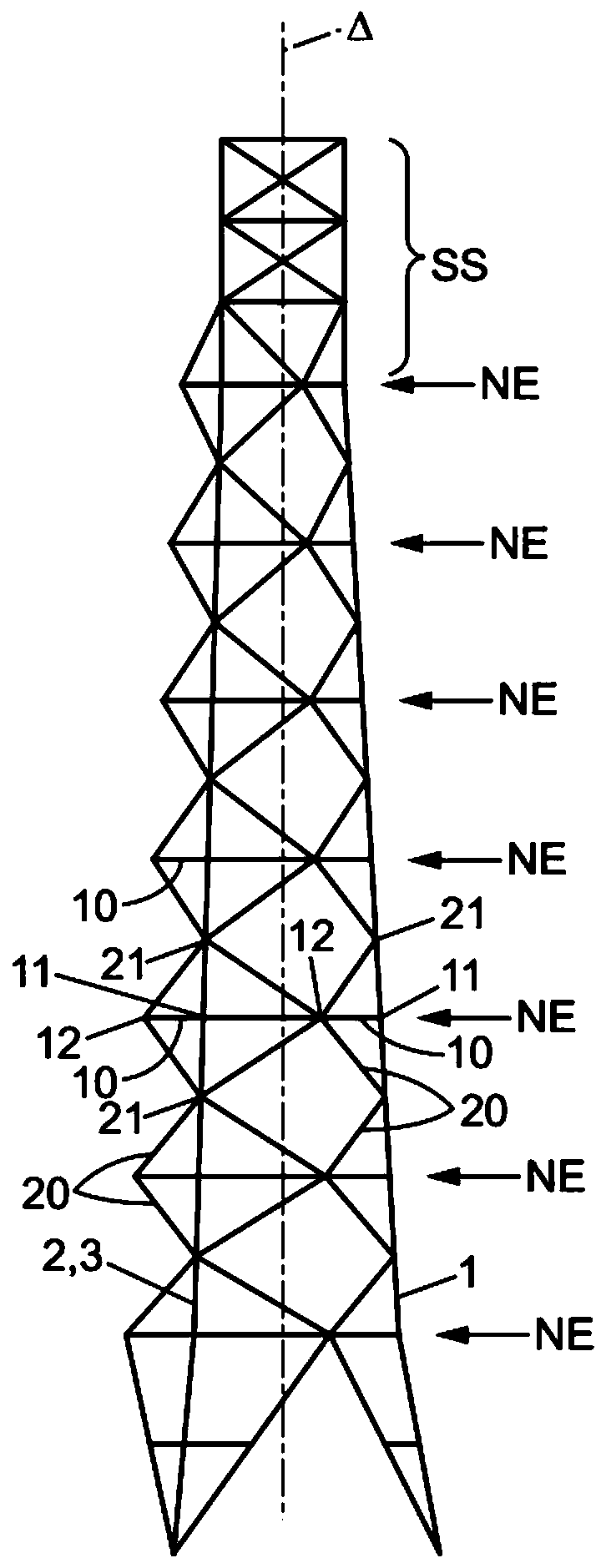

[0065] The axis Δ is vertical on the ground, and the tower structure assembly is threefold symmetric about the axis Δ. Uprights 1 to 3 are identical and each extend from the bottom of the structure to its top. The lower end of each column thus constitutes one of the three feet of the tower structure. The part of the tower structure below the lowest platform level is usually called the base or chassis, and the part between the lowest platform level and the highest platform level is usually called the running height, optionally added to the upper The structural member is called the roof.

[0066] In the first described embodiment, each column is parallel to the meridian containing the axis Δ, and the distance between the columns decreases towards the top of the structure, up to the highest platform level.

[0067] In any horizontal cross-section between the base and the top of the structure, the columns 1-3 define the vertices of an equilateral triangle.

[0068] Each platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com