Method and assistance system for recognising a fault in a system

An auxiliary system, technology for identifying equipment, applied in the field of interference and auxiliary systems for identifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

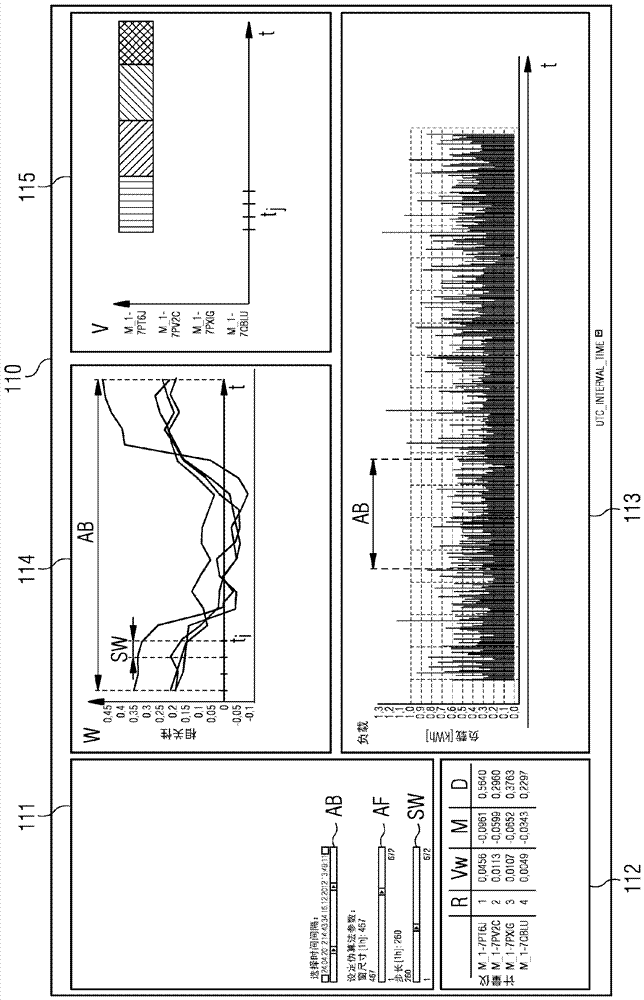

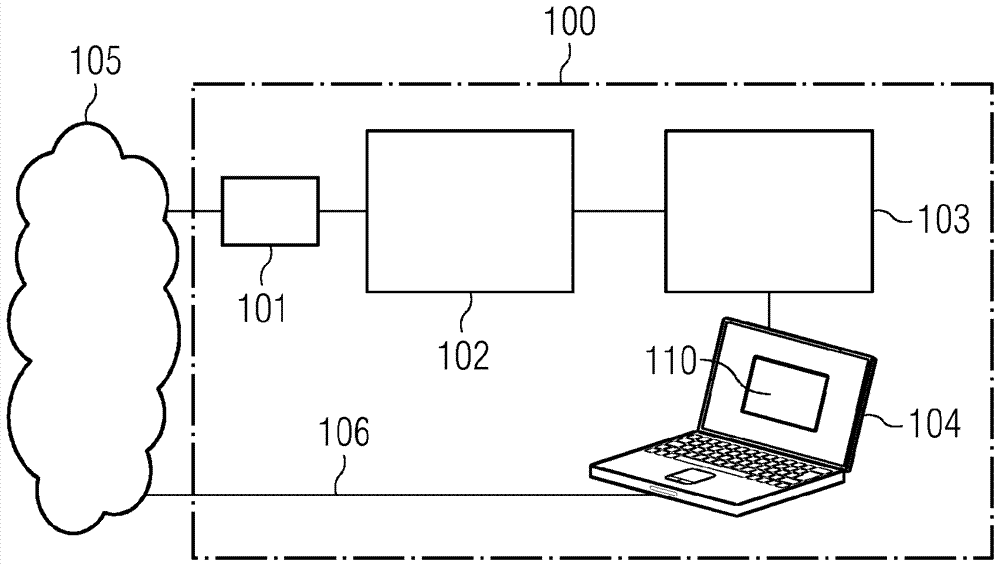

[0052] In plants such as industrial plants or manufacturing plants or also in electricity or water distribution networks, load curves over parameter values such as time or pressure are recorded, for example by means of field devices or consumption meters. In order to detect disturbances or unauthorized interventions in installations or to detect unauthorized withdrawals of electricity or water in the distribution network, these load curves can be studied by auxiliary systems for anomalies in these load curves and thus determined that the resulting those parts of these load curves. These components can then be changed or the abuse eliminated.

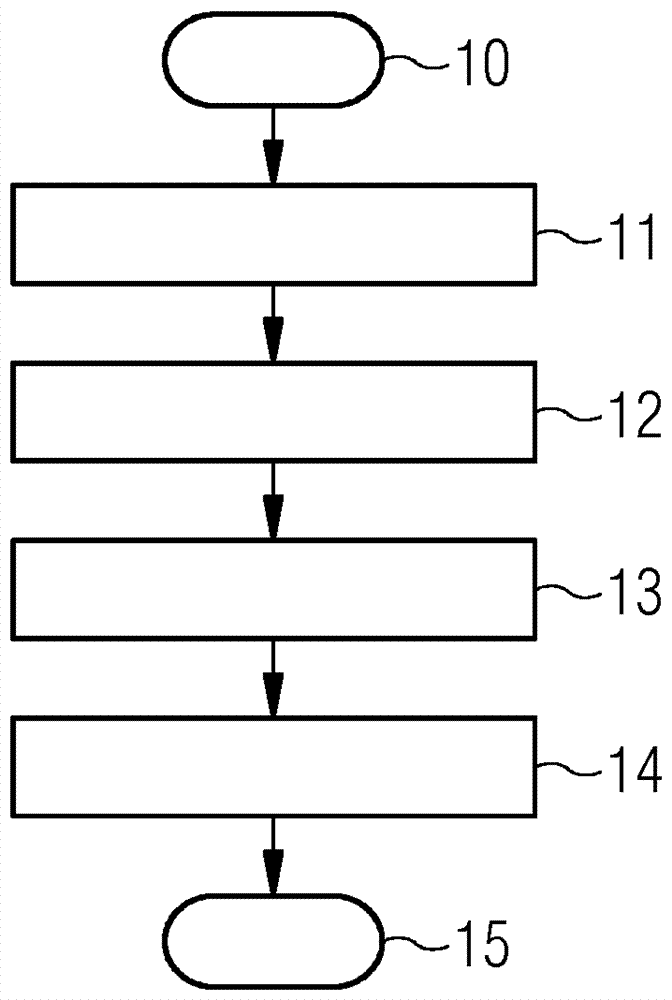

[0053] exist figure 1 The various method steps for detecting disturbances in a plant by detecting a load curve with an unusual course are schematically shown in . In the output state 10 there are several load curves, each load curve being generated by a specific component of the system. These load curves can already exist, for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com