Voice frequency core wire disengaging device

A technology for disengaging devices and core wires, which is applied in transportation and packaging, delivery of filamentous materials, and thin material processing, etc. It can solve the problems of wasting raw materials, economic loss, core wire stuck, time loss, etc., and avoid economic losses and time loss, avoiding the effect of stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

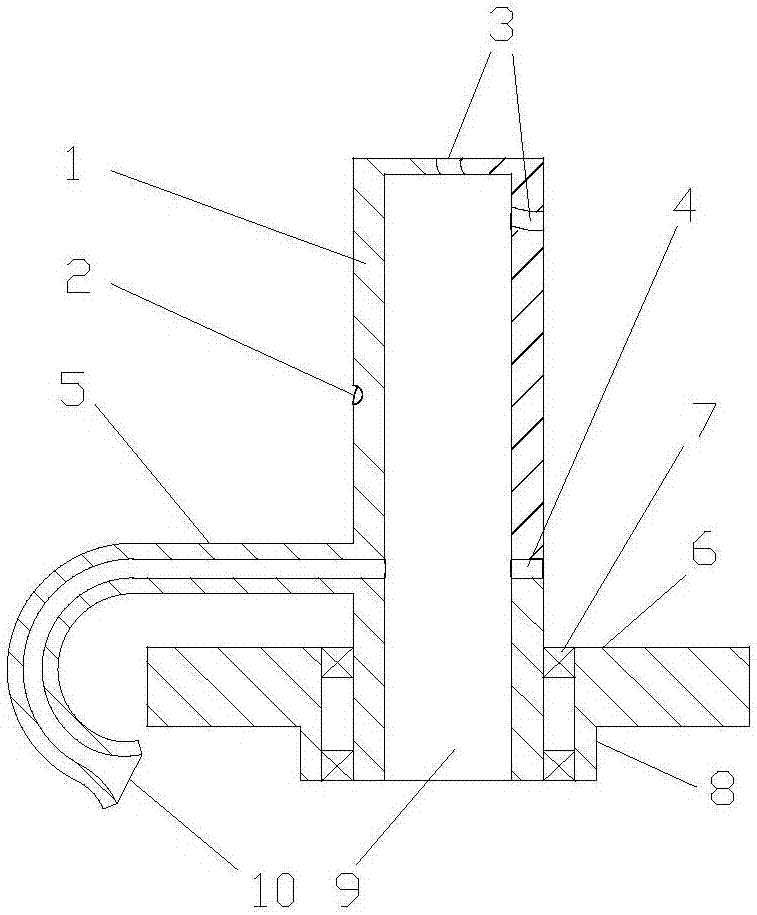

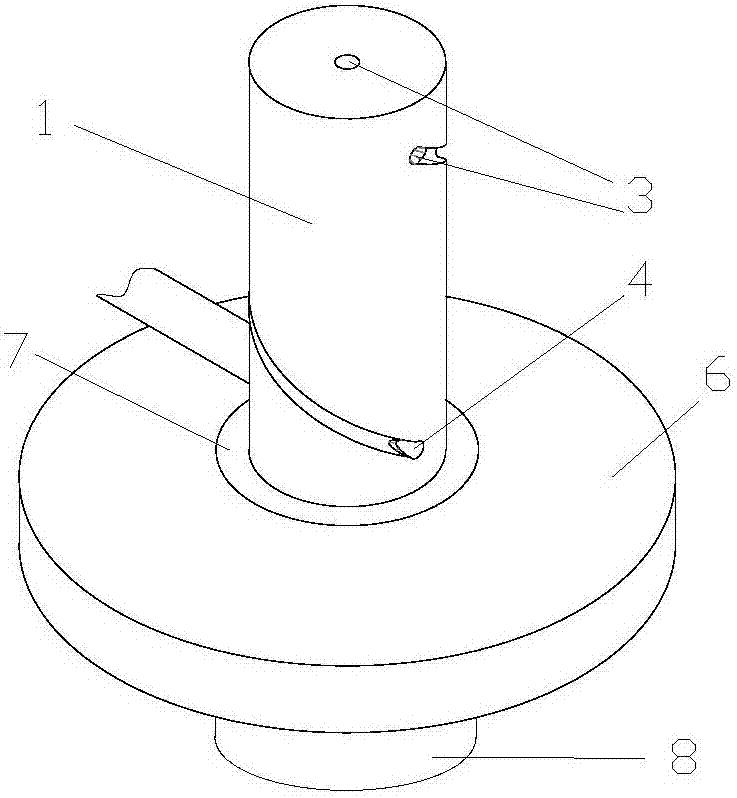

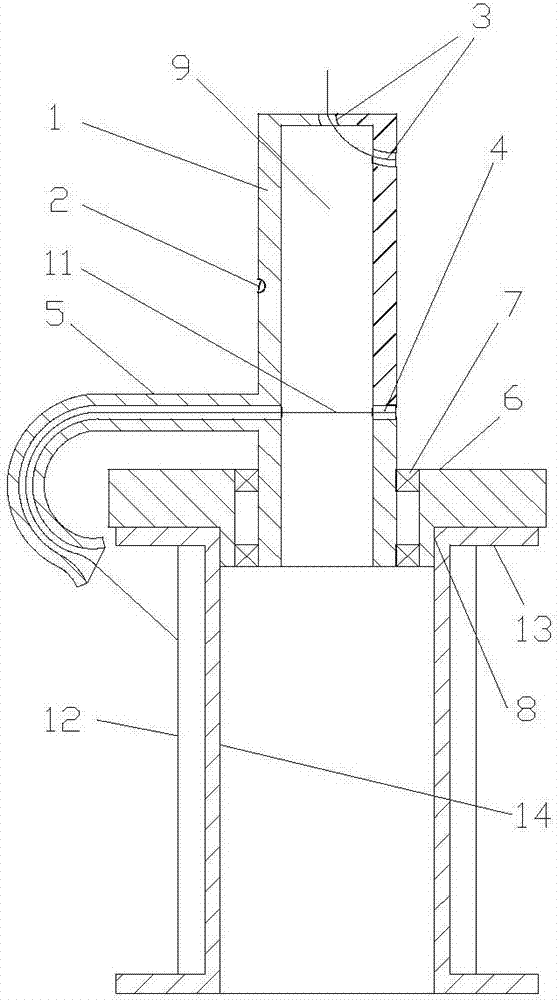

[0018] Example. An audio core wire release device, such as figure 1 and figure 2 As shown, it includes a cylindrical rotating shaft 1, a circle of coaxial helical grooves 2 is provided on the outer peripheral surface of the rotating shaft 1, and an upper through hole 3 communicating with the upper end of the groove 2 is arranged on the upper end surface of the rotating shaft 1, and the rotating shaft The side wall of the shaft 1 is provided with a lower through hole 4 that radially penetrates the shaft 1 and communicates with the lower end of the groove 2; the side wall of the shaft 1 is provided with a substantially J-shaped tubular body 5 communicating with the lower through hole 4. The J-shaped hook of the body 5 faces down and goes around the base 6. The hooked end of the tubular body 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com