Hoisting and righting method for tension tendon of tension leg platform

A technology of tension leg platforms and tension tendons, which is applied in the field of hoisting and righting of tension leg platforms and tension tendons of tension leg platforms, can solve problems such as difficult welding process, high cost and expensive manufacturing materials, and reduce construction work Risk, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

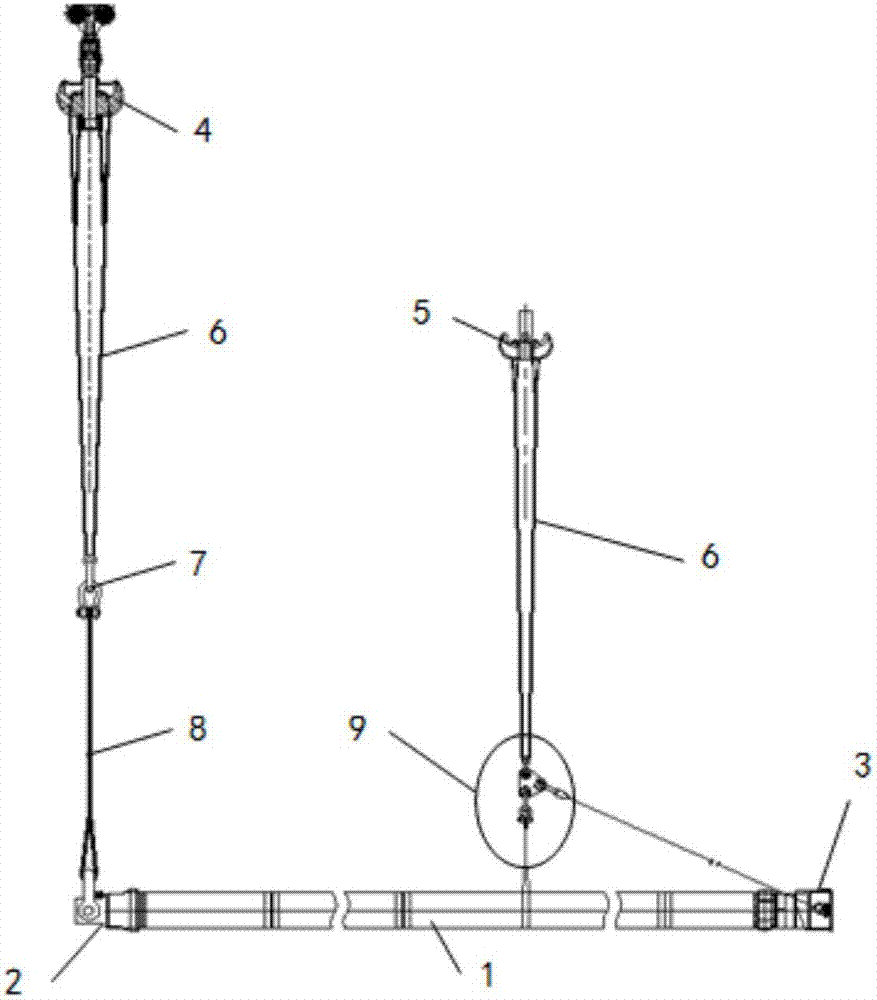

[0029] like figure 1 — Image 6 As shown, the present invention adopts the following installation steps:

[0030] Step 1: respectively arrange the upper section of the tension tendon and the main section 1 on the deck of the floating crane;

[0031] The second step: connect the hoist 2, the second rigging 8, the snap ring 7, and the first rigging 6 to form a floating sling hoisting device, so as to facilitate the pre-hanging rigging of the floating hook 4 and the installation of the hoist 2 ;

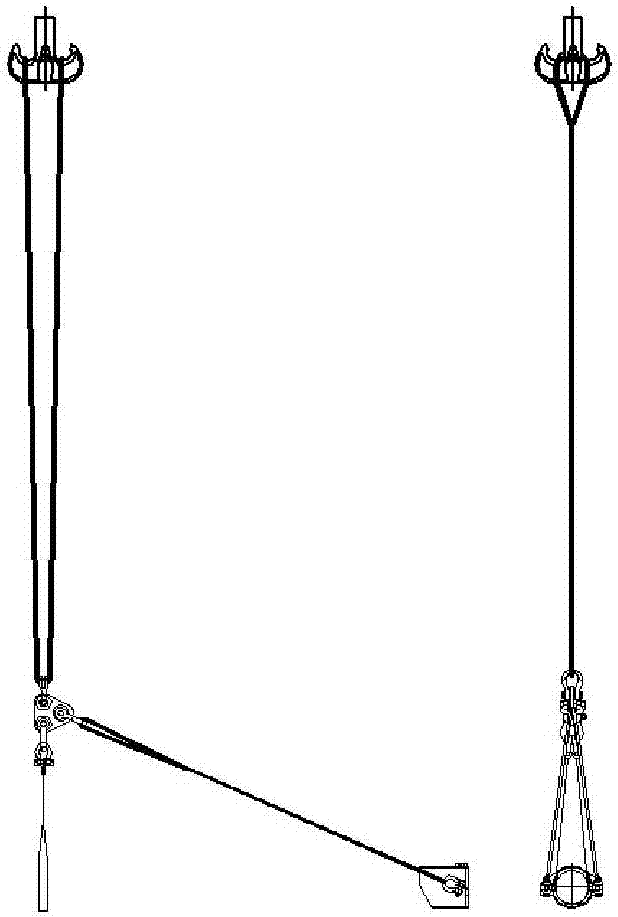

[0032] Step 3: If figure 2 As shown, the triangular plate auxiliary hoisting device 9 is pre-connected, so that the crawler hook 5 is pre-hanged on the rigging and the lifting bucket 3 is installed;

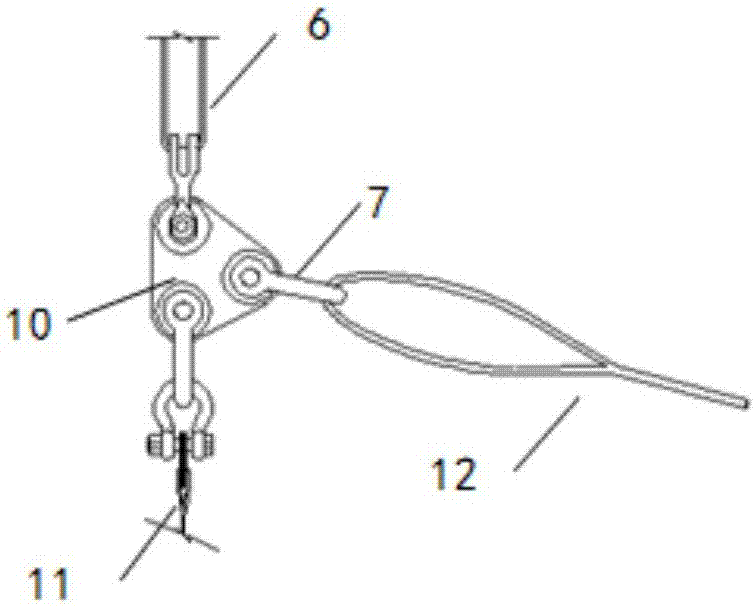

[0033] like image 3 As shown, the above-mentioned triangular plate auxiliary lifting device 9 includes: a triangular plate lifting lug 10, a snap ring 7 connecting the upper end of the triangular plate lug 10 and a first sling 6, a snap ring 7 connecting the lower end of the triangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com