Horizontally reinforced grouting underpinning working well and its manufacturing method

A technology of horizontal reinforcement and production method, applied in the direction of infrastructure engineering, construction, sheet pile wall, etc., can solve the problems of shaft wall inclination, surrounding ground subsidence, affecting the surrounding environment, etc., and achieve the effect of ensuring vertical verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

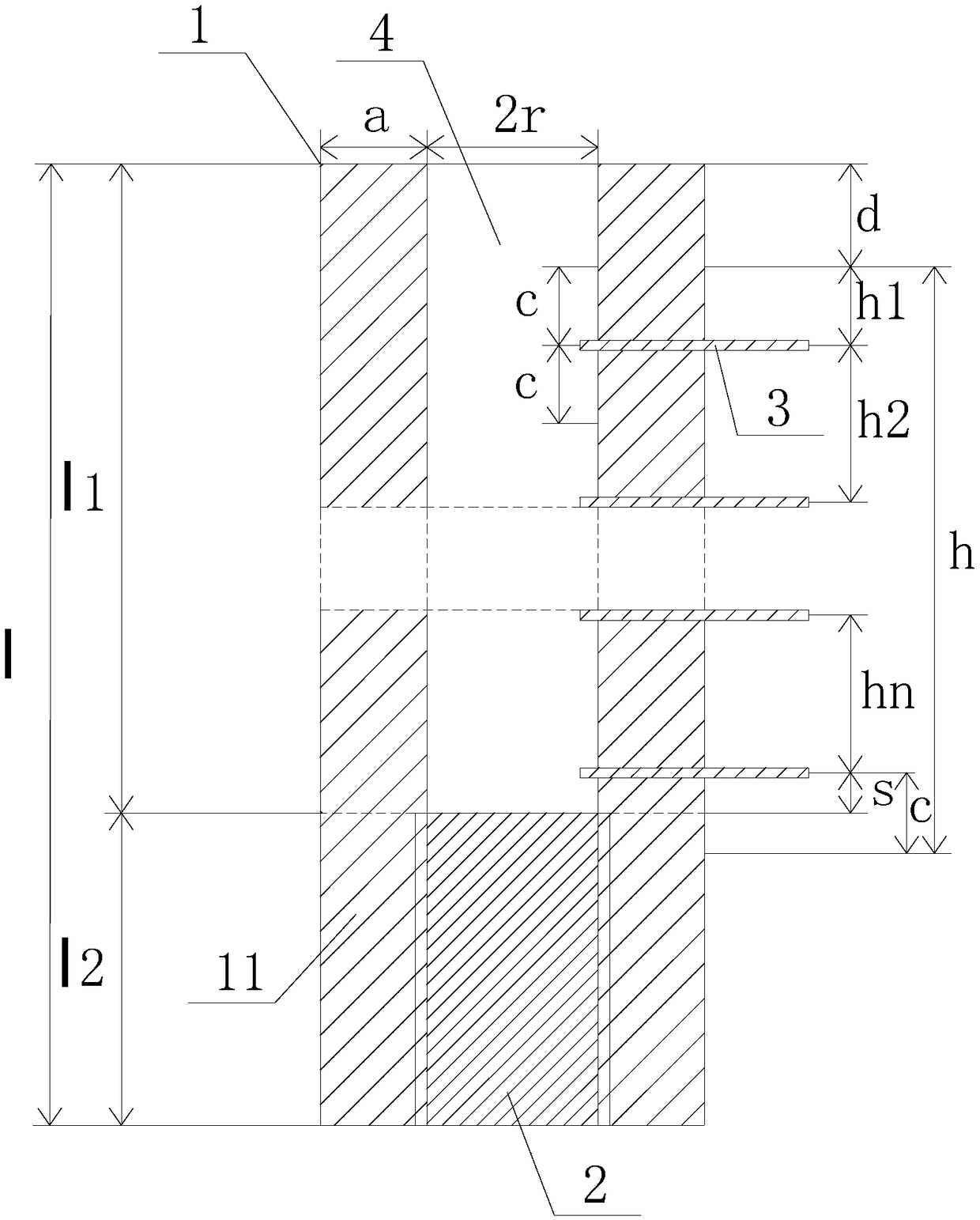

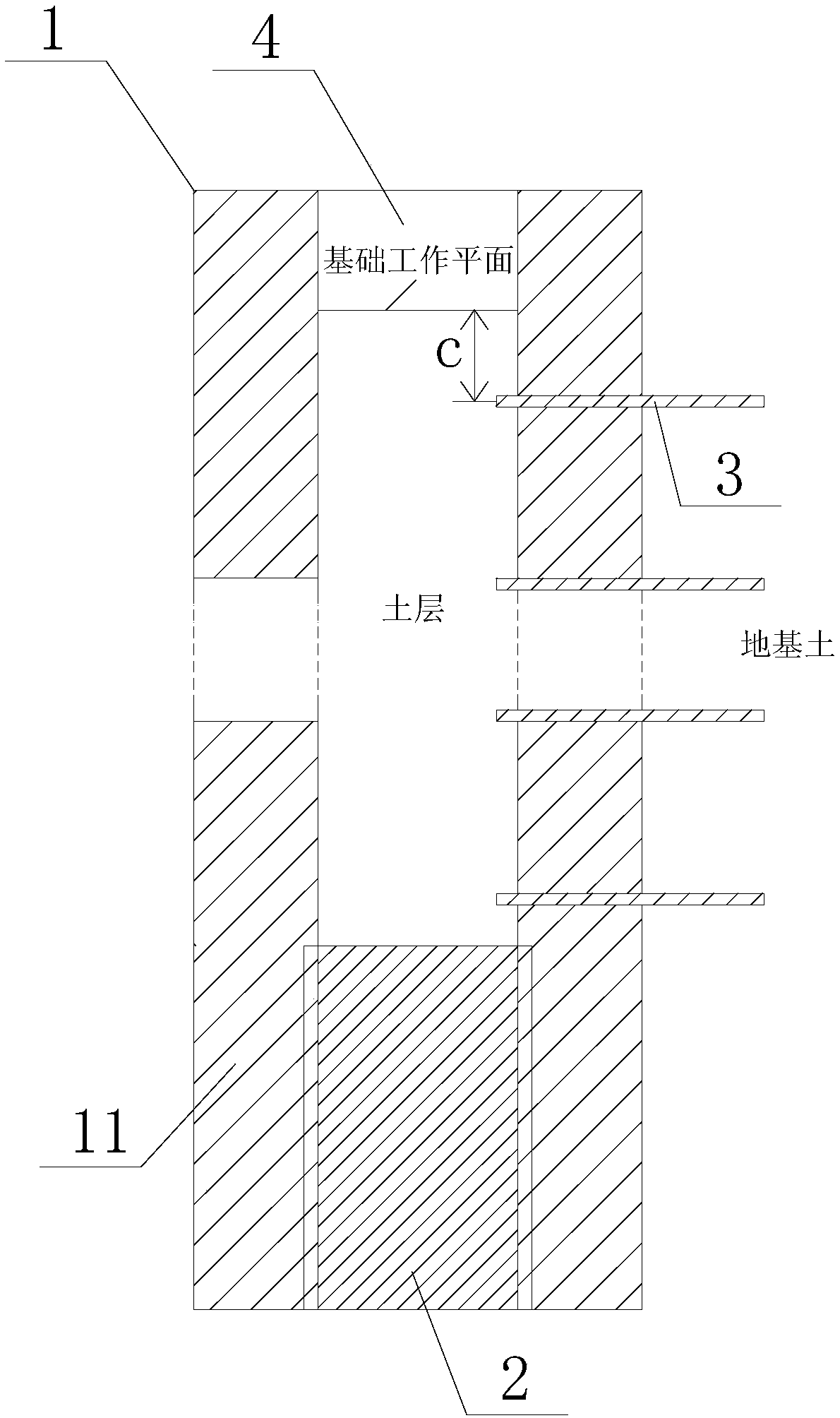

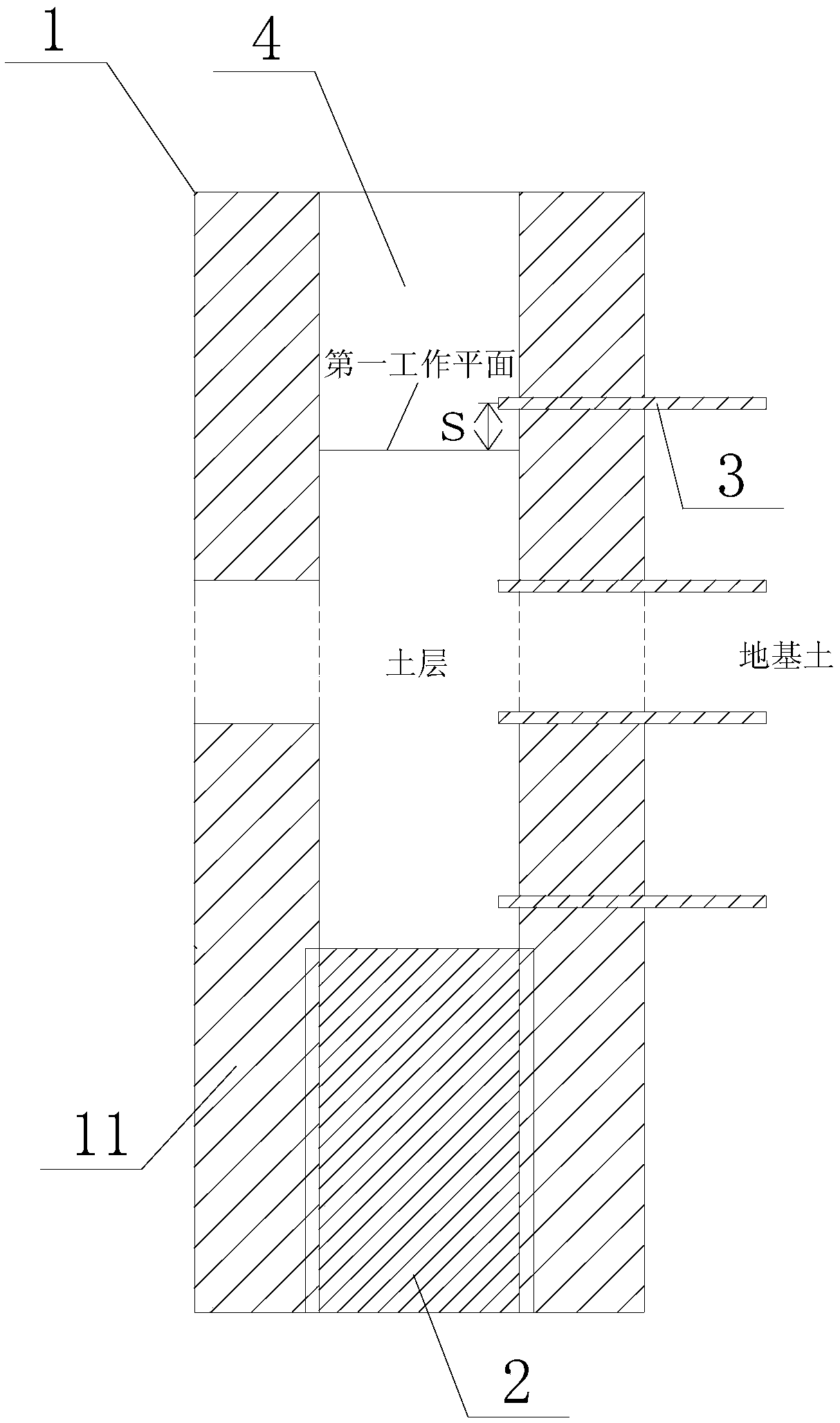

[0048] Embodiment 1, a kind of laterally reinforced grouting underpinning working well, such as Figure 1-7 As shown, it includes ring pile 1 and bottom cover pile 2; ring pile 1 is an approximate ring column formed by annular overlapping of at least four pile bodies 11 (eighteen pile bodies 11 are used in the figure), and the pile bodies 11 are mutually The lap joint length is t1, which can effectively isolate water and resist earth pressure. The bottom cover pile 2 is arranged at the bottom of the middle through hole of the ring pile 1, the bottom surface of the bottom cover pile 2 is parallel to the bottom surface of the ring pile 1, and the bottom cover pile 2 is overlapped with each pile body 11 of the ring pile 1, and the lap length is t2, thus The bottom of the through hole in the middle of the sealed annular pile 1 can effectively isolate water and resist earth pressure. General back cover pile 2 is one, also can adopt a plurality of back cover piles 2 to overlap when...

specific example 1

[0079] A building, the design requirement is: the depth of foundation d=1.0m, the foundation soil reinforcement thickness h=3.0m that needs, the grout diffusion radius of reinforced pipe under the foundation is c=1.5m, use the present invention to make working well:

[0080] The overlapping length t1=0.2m between two adjacent pile bodies 11 is preset, the overlapping length t2=0.2m between the bottom cover pile 2 and the annular pile 1, the radius r=0.8m of the working well space 4, and the construction distance s= 0.5m.

[0081] 1. According to the reinforcement thickness h of the foundation soil, determine the number n of reinforcement pipes 3:

[0082] n=h / (2c)=3 / (2×1.5)=1;

[0083] 2. Determine the height l1 of the working well space 4:

[0084] l 1 =d+h 1 +s=1.0+1.5+0.5=3.0m;

[0085] 3. Determine the height l2 of the back cover pile 2:

[0086] A reinforced pipe 3: l 2 =1.0+(n-1)×0.5=1.0m;

[0087] Four, determine the total length l of ring pile 1:

[0088] l=l ...

specific example 2

[0097] A building, the design requirement is: the depth of foundation d=1.0m, the foundation soil reinforcement thickness h=6.0m that needs, the grout diffusion radius of reinforced pipe under the foundation is c=1.5m, use the present invention to make working well:

[0098] The overlapping length t1=0.2m between two adjacent pile bodies 11 is preset, the overlapping length t2=0.2m between the bottom cover pile 2 and the annular pile 1, the radius r=0.8m of the working well space 4, and the construction distance s= 0.5m.

[0099] 1. According to the reinforcement thickness h of the foundation soil, determine the number n of reinforcement pipes 3:

[0100] n=h / (2c)=6 / (2×1.5)=2;

[0101] 2. Determine the height l1 of the working well space 4:

[0102] l 1 =d+h 1 + h 2 +s=1.0+1.5+3.0+0.5=6.0m;

[0103] 3. Determine the height l2 of the back cover pile 2:

[0104] Two reinforced pipes 3: l 2=1.0+(n-1)×0.5=1.0+(2-1)×0.5=1.5m;

[0105] Four, determine the total length l of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com