Thin film used for non-formaldehyde environmental friendly wood floor and preparation method thereof

A wooden floor, environmental protection technology, applied in the direction of construction, building structure, floor, etc., can solve the problems of slow release, wooden floor waterproof, poor moisture-proof effect, unhygienic and environmental protection, etc., and achieve good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

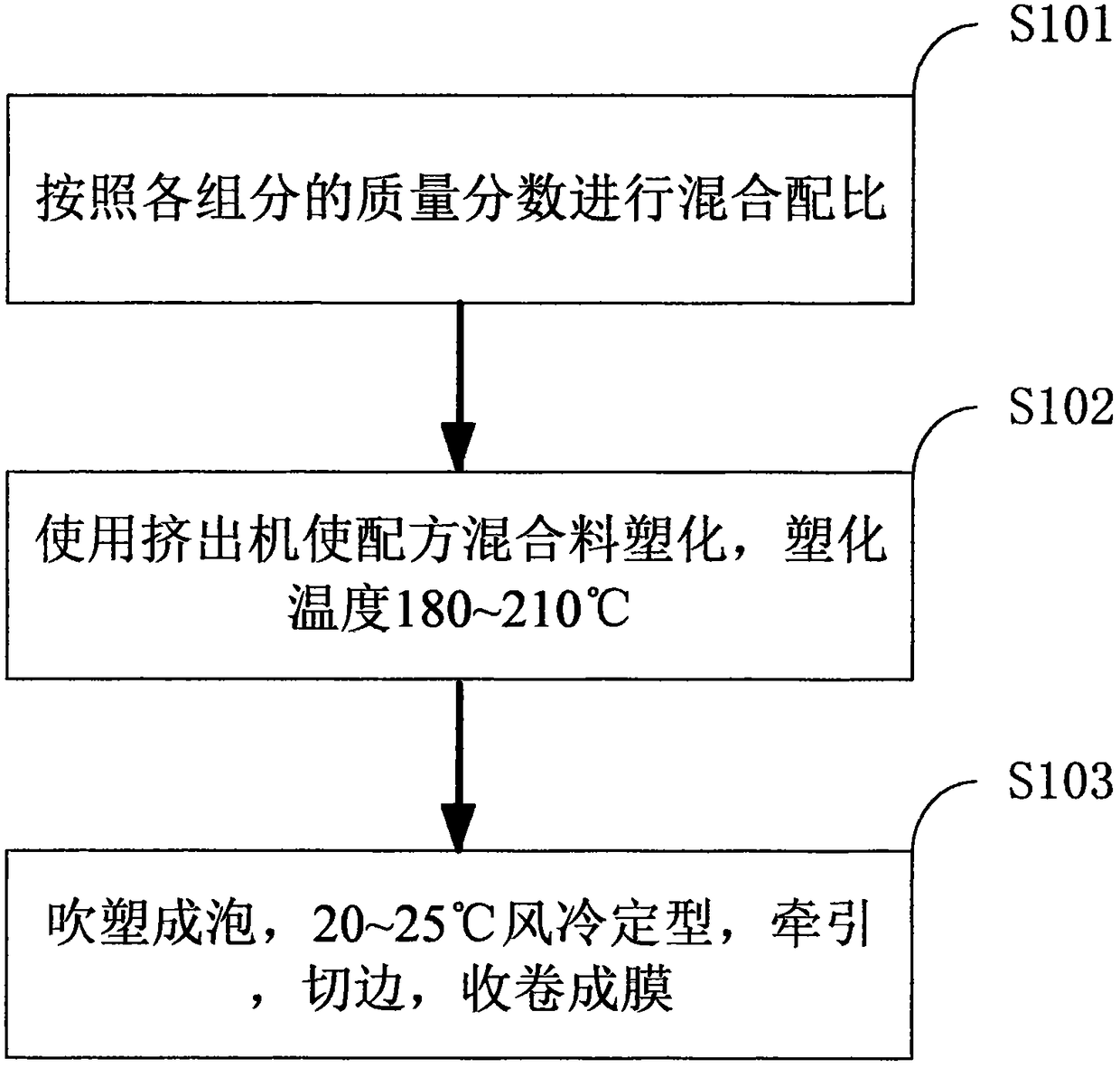

[0029] Such as figure 1 As shown, the preparation method of the film for formaldehyde-free environmental protection wooden floor that the embodiment of the present invention provides comprises:

[0030] S101: mixing and proportioning according to the mass fraction of each component;

[0031] S102: Using an extruder to plasticize the formula mixture, the plasticizing temperature is 180-210°C;

[0032] S103: Blow molding into foam, air-cooled at 20-25°C for shaping, traction, trimming, and winding into film.

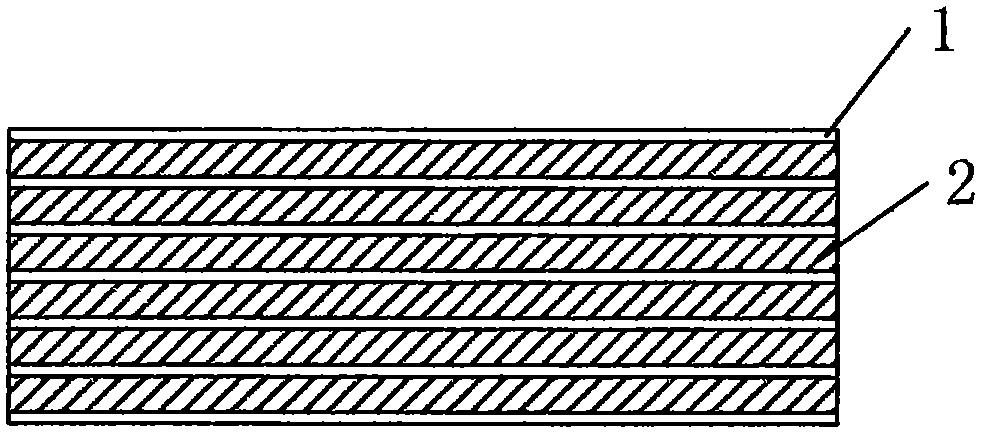

[0033] figure 2 It is a formaldehyde-free environment-friendly wooden floor structure provided by the embodiment of the present invention, which is composed of film 1 and wood chips 2 .

Embodiment 1

[0035] Select 100 parts of HDPE, 1 part of EVA with a VAC content of 10%, 1 part of MA-PE with an acid value of 8 and 20 parts of fillers;

[0036] Use an extruder to plasticize the formula mixture, and the plasticizing temperature is 180°C;

[0037] Blow molding into foam, air-cooled at 20°C for shaping, traction, edge trimming, and winding into film.

Embodiment 2

[0039] Select 100 parts of HDPE, 7 parts of EVA with a VAC content of 20%, 10 parts of MA-PE with an acid value of 9 and 10 parts of fillers;

[0040] Use an extruder to plasticize the formula mixture, and the plasticizing temperature is 200°C;

[0041] Blow molding into foam, air-cooled at 22°C for shaping, traction, edge trimming, and winding into film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com