Greenhouse chemical fiber heat preservation cotton and equipment thereof

A technology for greenhouses and thermal insulation cotton, which is applied in the fields of greenhouse cultivation, botanical equipment and methods, fiber processing, etc., can solve the problems of poor mixing degree of raw materials, affecting the thermal insulation effect, etc., so as to improve the mixing degree, reduce the interference of feeding, Improve the effect of mixing and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

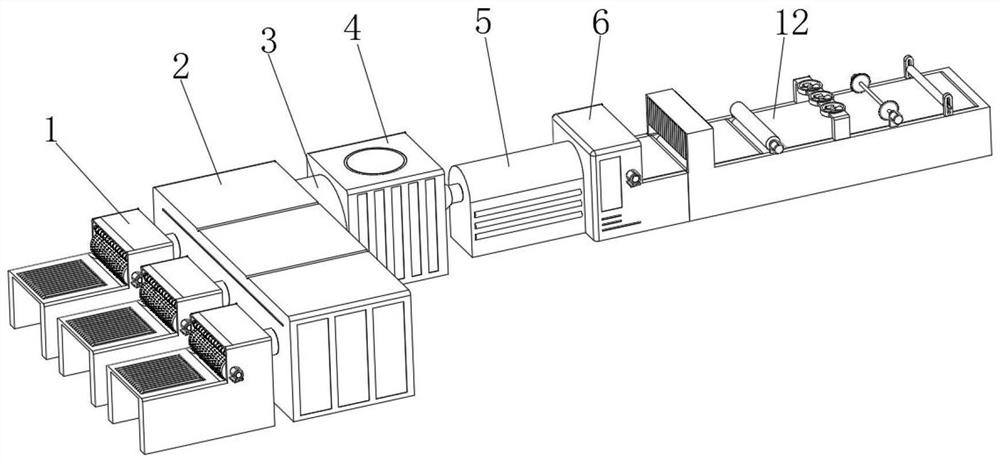

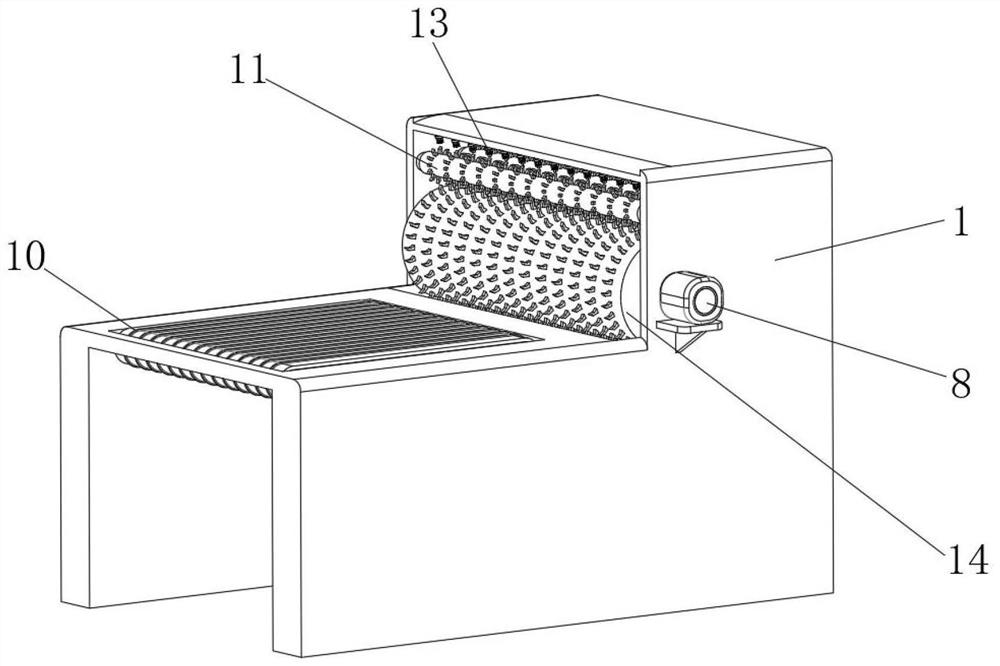

[0068] A kind of equipment for greenhouse chemical fiber thermal insulation cotton, such as Figure 1-9 As shown, it comprises opening device 1, mixing air chamber 2, wind conveying channel 3, secondary mixing chamber 4, baking chamber 5, carding machine 6 and conveying platform 33, and the output end of described opening device 1 is all connected with mixing The inside of the air chamber 2 is connected, and the mixing air chamber 2 is connected to the inside of the secondary mixing chamber 4 through the wind conveying channel 3. The output end of the secondary mixing chamber 4 is connected to the input end of the baking chamber 5, and the baking The output end of the chamber 5 is connected to the feed end of the carding machine 6, the delivery platform 33 is arranged on the discharge end of the carding machine 6, the opening device 1 is provided with a feed conveyor belt 9 for feeding, and the A mixing bucket 7 is welded on the outer wall of the secondary mixing chamber 4 nea...

Embodiment 2

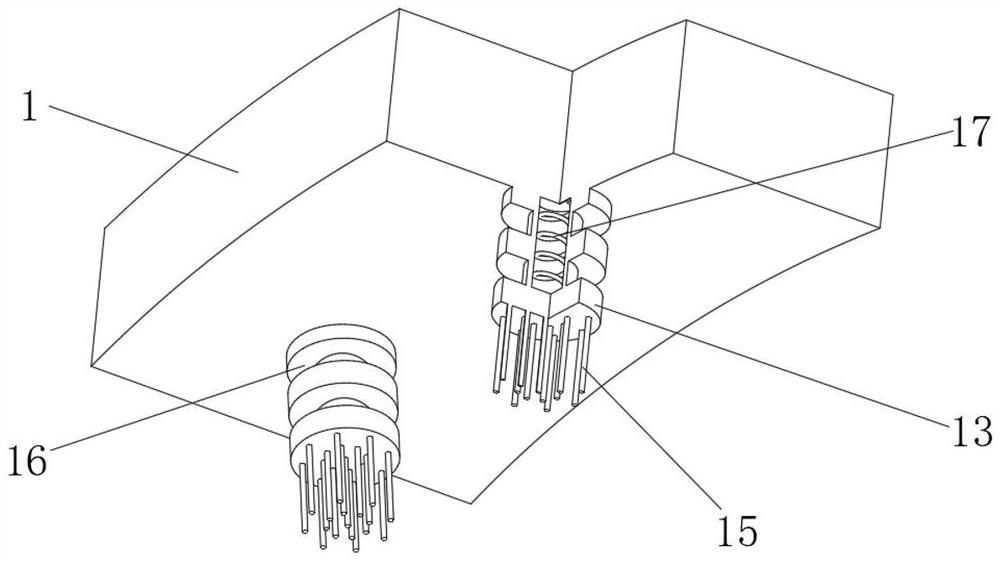

[0082] A kind of equipment for greenhouse chemical fiber thermal insulation cotton, such as Figure 10 As shown, in order to improve the opening effect; this embodiment makes the following improvements on the basis of Embodiment 1: the outer peripheral wall of the roller 11 is fixed with evenly distributed spiral seats 44 by screws, and the outer surface of the spiral seat 44 is integrated. Equidistantly distributed opening teeth 45 are arranged in the same way; by setting the screw seat 44 and the opening teeth 45, it can fully contact with the material, thereby further improving the opening effect and ensuring the product quality and functionality of the finished product .

Embodiment 3

[0084] A kind of greenhouse chemical fiber thermal insulation cotton, such as Figure 1-12 As shown, in parts by weight, the composition includes: 45-55 parts of polyester, 15-25 parts of polypropylene, and 30-40 parts of 4080 staple fiber.

[0085] The production technology of described thermal insulation cotton comprises the steps:

[0086] S1: Recycling car interiors as raw materials, washing and crushing;

[0087] S2: Put each raw material into the greenhouse chemical fiber insulation cotton equipment described in Example 1 according to the proportion, and open and mix through the opening device 1, the mixing air chamber 2, the wind conveying channel 3 and the secondary mixing chamber 4 in sequence deal with;

[0088] S3: Adjust the temperature of the baking chamber 5 according to the actual situation, heat-dry the mixed thermal insulation cotton, adjust the parameters of the carding machine 6, and comb the heat-dried material into shape;

[0089] S4: Control the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com